Rapid paint grinding machine

A grinding machine and paint technology, applied in the field of grinding machines, can solve the problems of reducing the number of processing, tool damage, sample waste, etc., and achieve the effect of reducing feeding time, avoiding collision, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

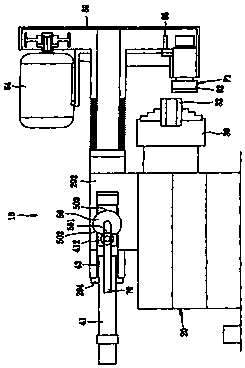

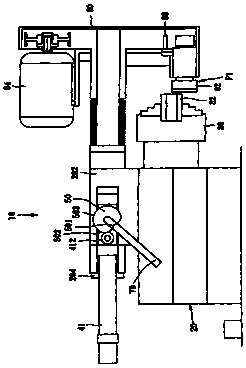

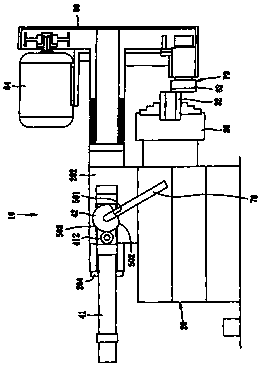

[0019] Such as figure 1 and Figure 4 As shown, a quick paint grinder 10 provided by an embodiment of the present invention mainly includes a base 20 , a fixing mechanism 30 , a conveying mechanism 40 , a wheel shaft 50 , a supporting frame 60 and a motor 70 .

[0020] There is a connecting portion 202 above the base 20 , and the connecting portion 202 is provided with a shield 204 .

[0021] The fixing mechanism 30 is fixed on the side of the base 20 . In this embodiment, the fixing mechanism 30 is embodied by a clamp, and the clamp holds a sample 32 .

[0022] The conveying mechanism 40 is arranged on the junction 202, and the conveying mechanism 40 can carry out axial displacement at the junction 202. The conveying mechanism 40 has a driving shaft 41, a telescoping rod 43, a driven shaft 44, a knob 45, a rotating shaft 46 and connectors 47.

[0023] The front end of the driving shaft 41 is sleeved in the joint 202 , and a roller 412 is provided on one side of the driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com