Hot-melting edge sealing fixture

A hot-melt and jig technology, which is applied in the field of film processing, can solve the problems of being small, breaking with a little force, breaking at the edge seal, and easy to break, so as to achieve difficult to break, high processing efficiency and low processing cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

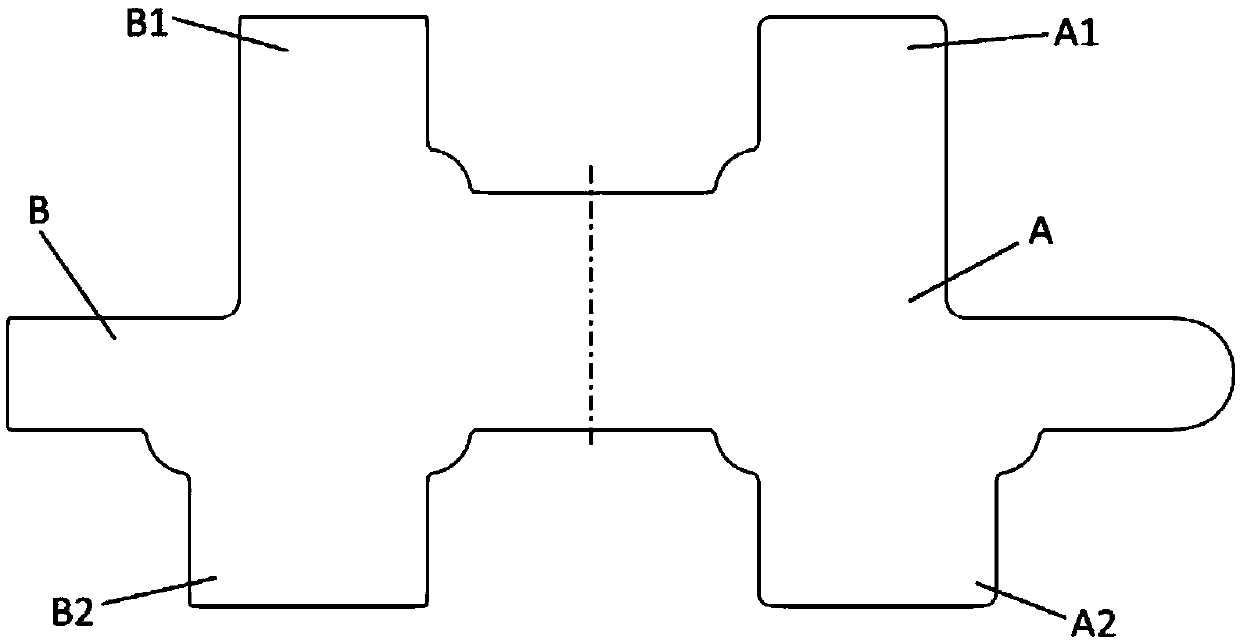

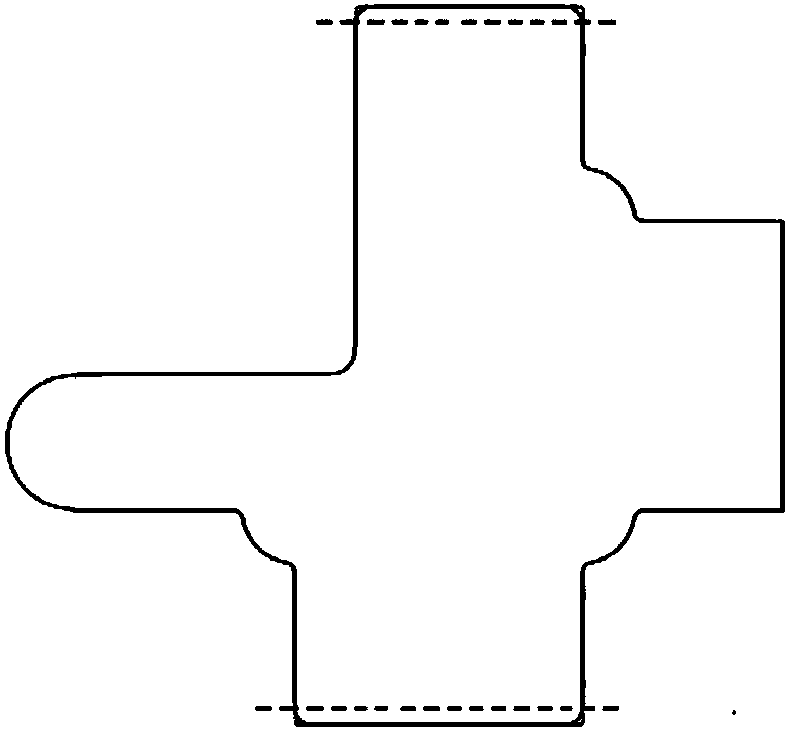

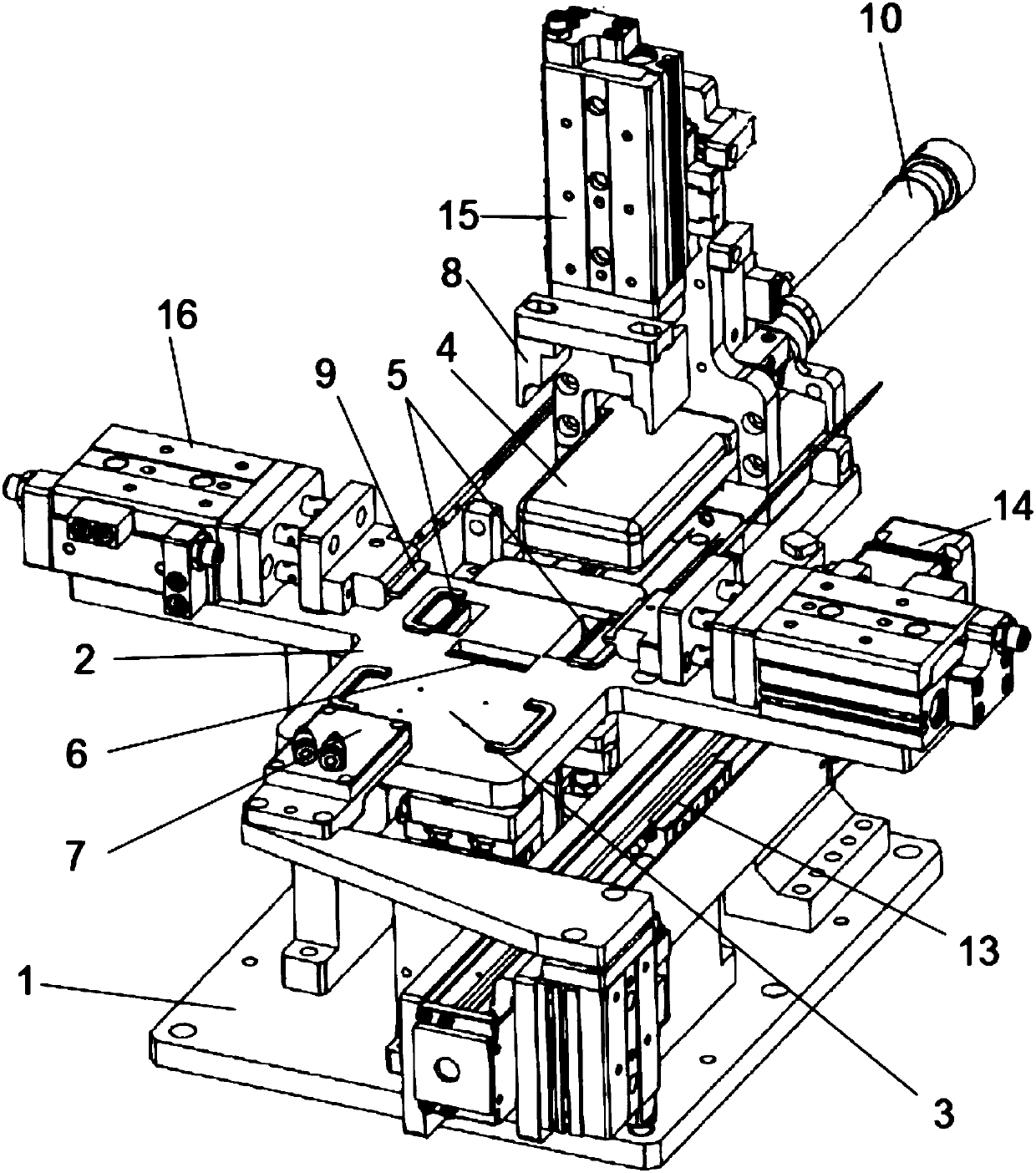

[0019] Such as Figure 3 to Figure 5 As shown, this embodiment provides a hot-melt edge sealing jig, which includes a jig seat and a worktable 2 fixed above the jig seat; a film fixing groove 3 is provided in the middle of the worktable 2; The film fixing groove 3 is provided with a film cavity fixing block 4 at the rear; the film fixing groove 3 is located at the fourth side B2 and the third side B1 of the film, respectively, with holes, and correspondingly arranged side folds in the holes The plate 5 is also provided with a hole in the front position between the two side lower folding plates 5, and a front folding plate 6 is provided in the hole; a push-up folding plate 7 is provided above the front end of the film fixing groove 3 The film cavity fixing block 4 is fixed on a moving frame provided behind the workbench 2, and the upper side of the moving frame is located directly above the film cavity fixing block 4 with a side upper folding frame 8; the side Both ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com