Fusion-splicing clamping device for C lens

A clamping and lens technology, which is applied to other home appliances, optical components, home appliances, etc., can solve the problems of coating surface damage, trouble, low efficiency, etc., and achieve the effect of low cost, convenient and efficient operation, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described with reference to the drawings.

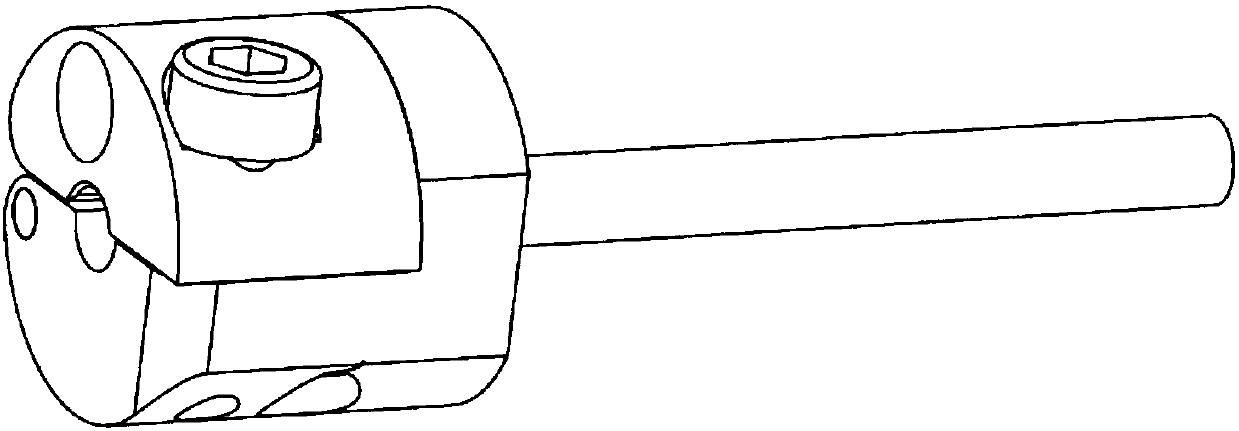

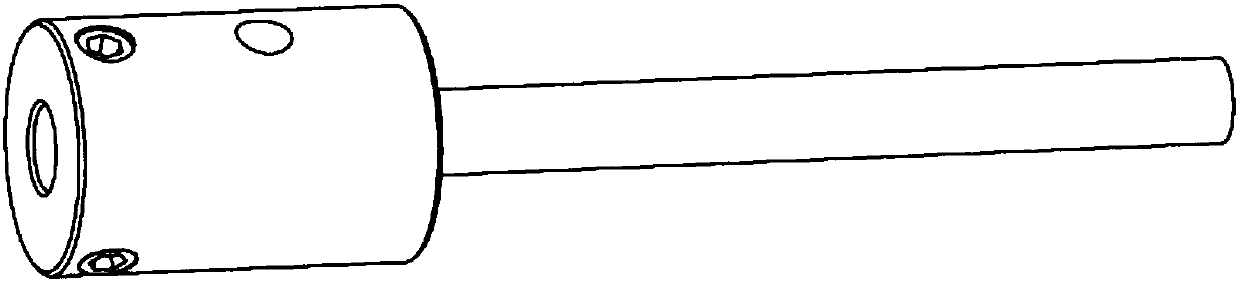

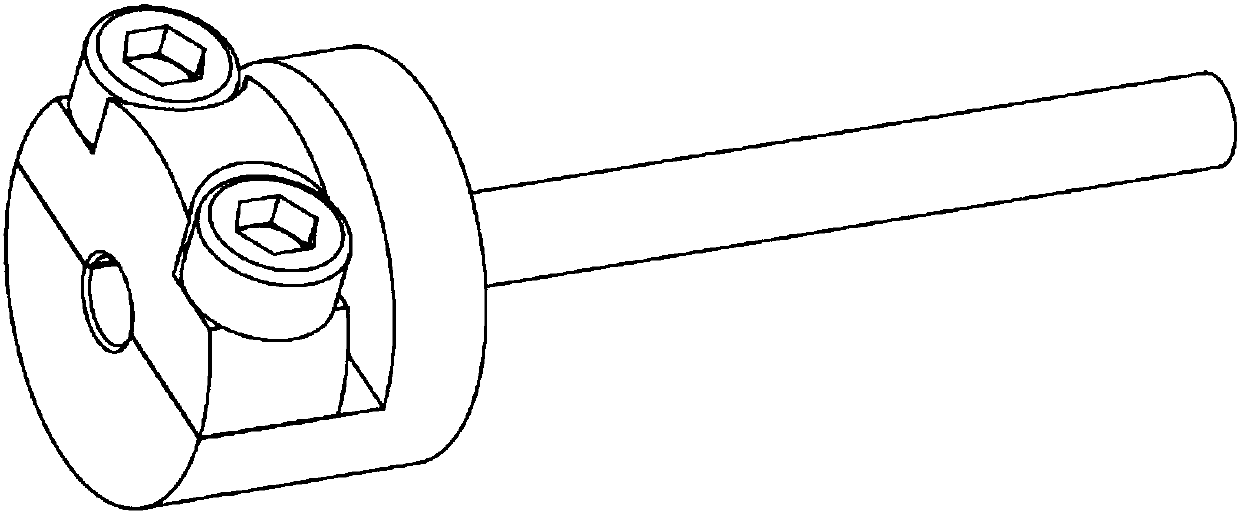

[0026] At present, there are two common methods. The first method is to put the C lens into the small hole of the holding device and press it with a set screw, such as figure 2 As shown, the drawback of this method is that it is easy to cause damage to the coating surface, because the C lens and the mounting hole are precisely matched, and the centering adjustment is required before installation, and the coating surface will inevitably touch the edge of the orifice and be damaged; second One method is to use a separate cover to compress the C lens with a screw, such as image 3 As shown, the disadvantage of this method is that the operations of pressing the C lens by pressing the cap and releasing the C lens are very troublesome and low in efficiency.

[0027] Such as figure 1 , Figure 4 , Figure 5 As shown, a C lens welding device includes a connecting rod 100, a clamping base 101, a gland 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com