A low-temperature plastic bottle dairy product filling production line with anti-scratch code marking

A dairy product and production line technology, which is applied in the field of special equipment for dairy product processing, can solve problems such as increased bad feedback information, unclear coding, and incomplete coding, so as to achieve accurate and complete production information records and marks, and improve the accuracy of coding work Degree, to avoid the effect of fancy codes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

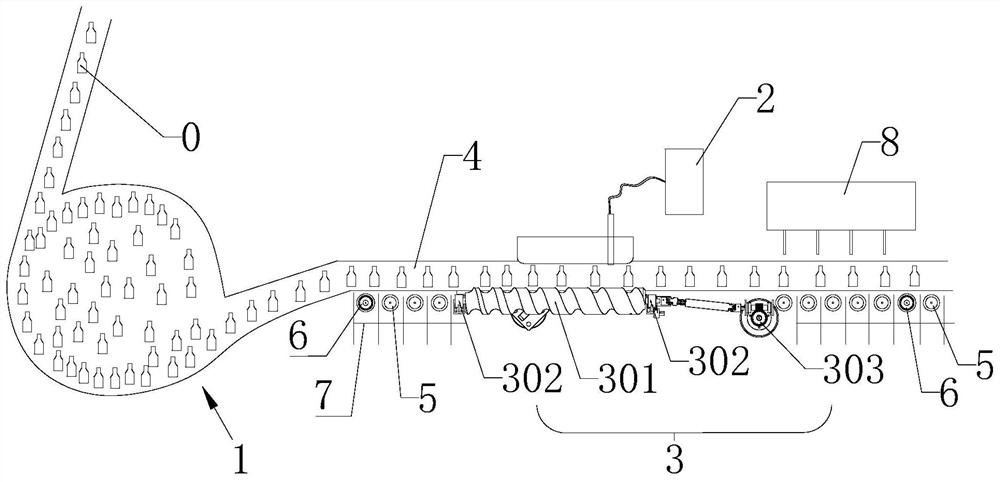

[0041] Such as figure 1The shown plastic bottle dairy product filling production line is provided with input guide rails in sequence, bottle unscrambler 1, conveying mechanism, inkjet printer 2, filling machine 8, and bottle divider 3 are set on the opposite side of the inkjet printer and the conveyor belt. Empty bottles 0 (unfilled plastic bottles of dairy products) enter the bottle unscrambler 1 through the input guide rail, sort and transport to the conveyor belt 4 of the conveying mechanism. A power shaft 6 and a driven shaft 5 are installed on the support frame 7 , the conveyor belt 4 is mounted on the power shaft 6 and the driven shaft 5 , and the conveyor belt 4 transports plastic bottles 0 of dairy products. A bottle separator 3 is provided on the opposite side of the conveyor belt 4 adjacent to the inkjet printer 2, and the bottle separator 3 is used to control the distance between the plastic bottles 0 (that is, empty bottles) on the conveyor belt, while maintaining ...

Embodiment 2

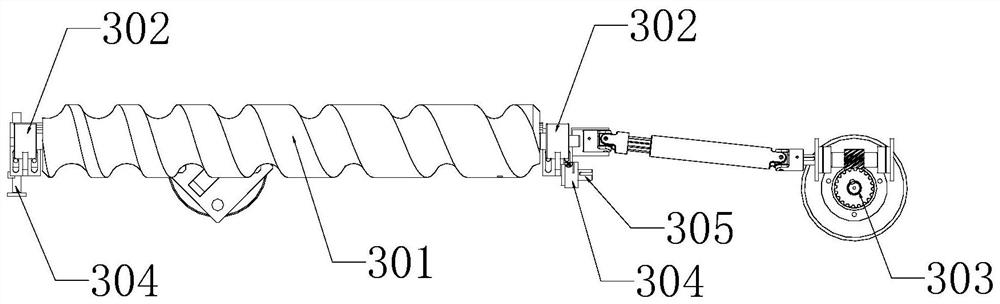

[0043] Such as figure 1 As shown, the dairy product filling production line is the same as in Embodiment 1, the inkjet printer is located upstream of the filling machine, and the empty bottle is first passed through the inkjet printer and then transported to the filling machine. The inkjet printer is installed on the side of the conveying mechanism, and cooperates closely with the conveying mechanism. On the opposite side is the screw of the bottle divider 3. The plastic bottle is adjusted and stabilized by the screw 301 to complete the excellent inkjet effect. The screw 301 is installed on the side of the conveyor belt through the corresponding screw installation base 302, and then connected to the bottle divider motor 303 through the ball shaft. The adjustment of the working state of the bottle divider can be realized by dynamically adjusting the speed of the bottle divider motor to achieve dynamic adaptation, and the fixed speed of the bottle divider motor can be set to ach...

Embodiment 3

[0047] The same dairy product filling production line as in Example 2, the production line also includes a hot air dryer, which is used to dry the water mist / droplets on the plastic bottle. At the same time, a plastic bottle sleeve labeling machine is also included after the filling machine, and the air dryer is arranged downstream of the plastic bottle sleeve labeling machine. After the plastic bottle is sleeved, it is dried by an air dryer, and the overall surface condition of the plastic bottle is better.

[0048] Furthermore, the bottle divider adopts a screw bottle divider, and the thread width at the rear end of the screw is 0.98-0.99 of the diameter of the plastic bottle. When the plastic bottle interacts with the screw, the plastic bottle at the rear end of the divider no longer vibrates, and the stability is very prominent , Compared with the 1:1 matching bottle divider, it has better stability. The continuous observation of 200+ plastic bottles is very clear and com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com