Bicycle tire production line

A technology for production lines and bicycles, applied in tires, other household appliances, household appliances, etc., can solve the problems of greater harm, great harm to human body, and slow manual operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

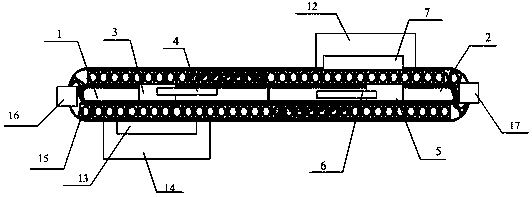

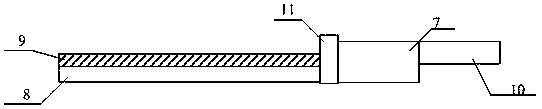

[0013] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0014] Such as Figure 1 to Figure 2 Shown, a kind of bicycle tire production line, it comprises the first production mechanism 1, the second production mechanism 2, transmission chain 9, mold 15, fixed template 18, transmission chain 9 is installed on the base 8, the first production mechanism 1 and the second The two production mechanisms 2 are all installed on the conveyor chain 9, several fixed templates 18 are installed on the conveyor chain 9, and several molds 15 are installed on the fixed template 18, and are driven by the conveyor chain 9 to rotate,

[0015] The first production mechanism 1 comprises the first manipulator base 3, the first manipulator 4, the second centrifuge 13, the second baffle 14 and the bristle brush 16, the first manipulator 4 is connected with the first m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com