Patents

Literature

30results about How to "No manual handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

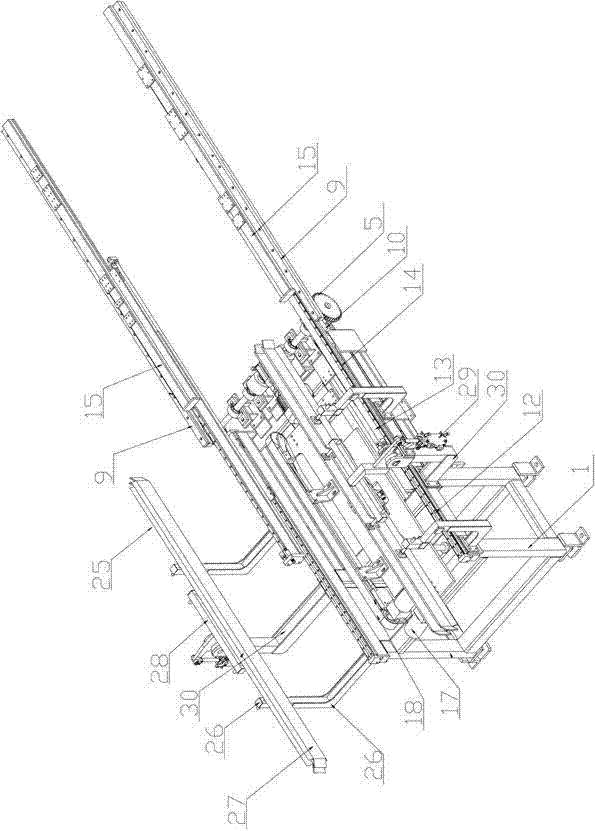

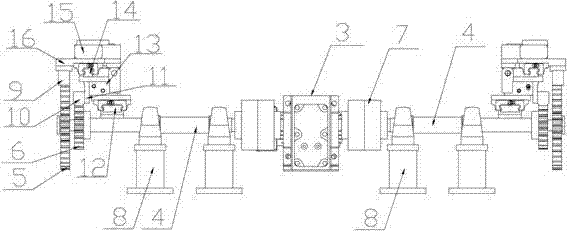

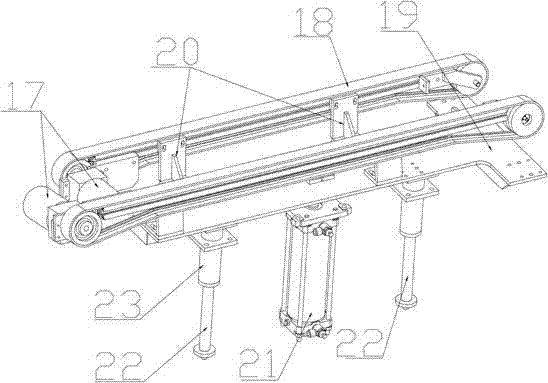

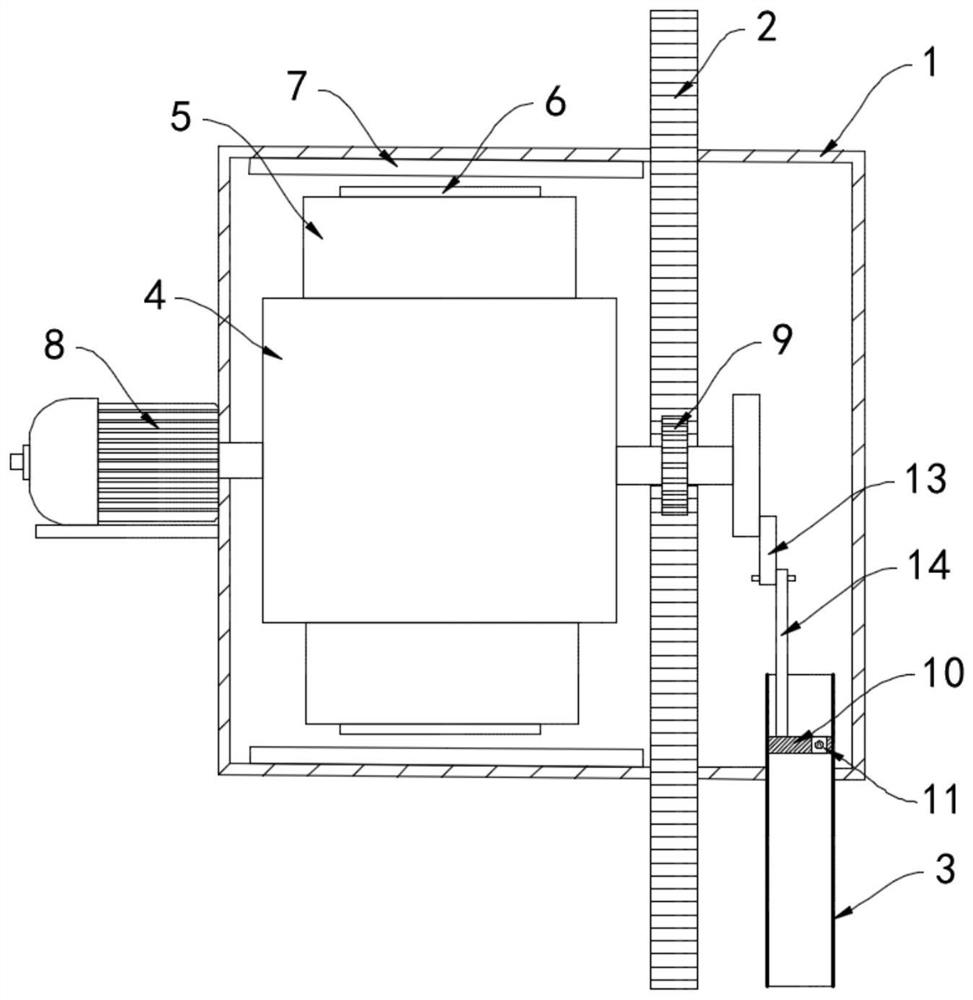

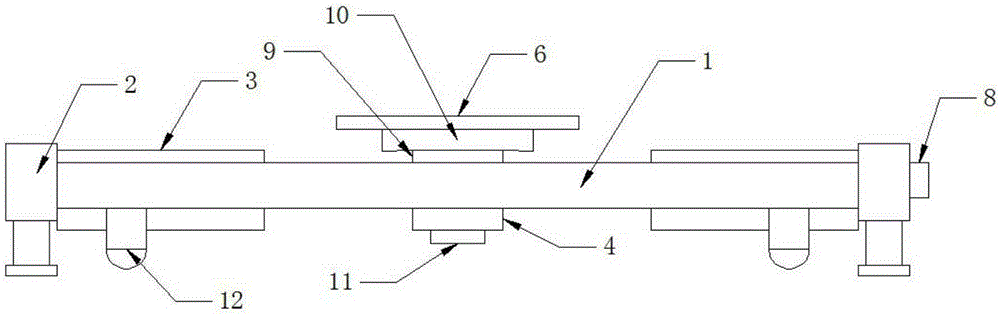

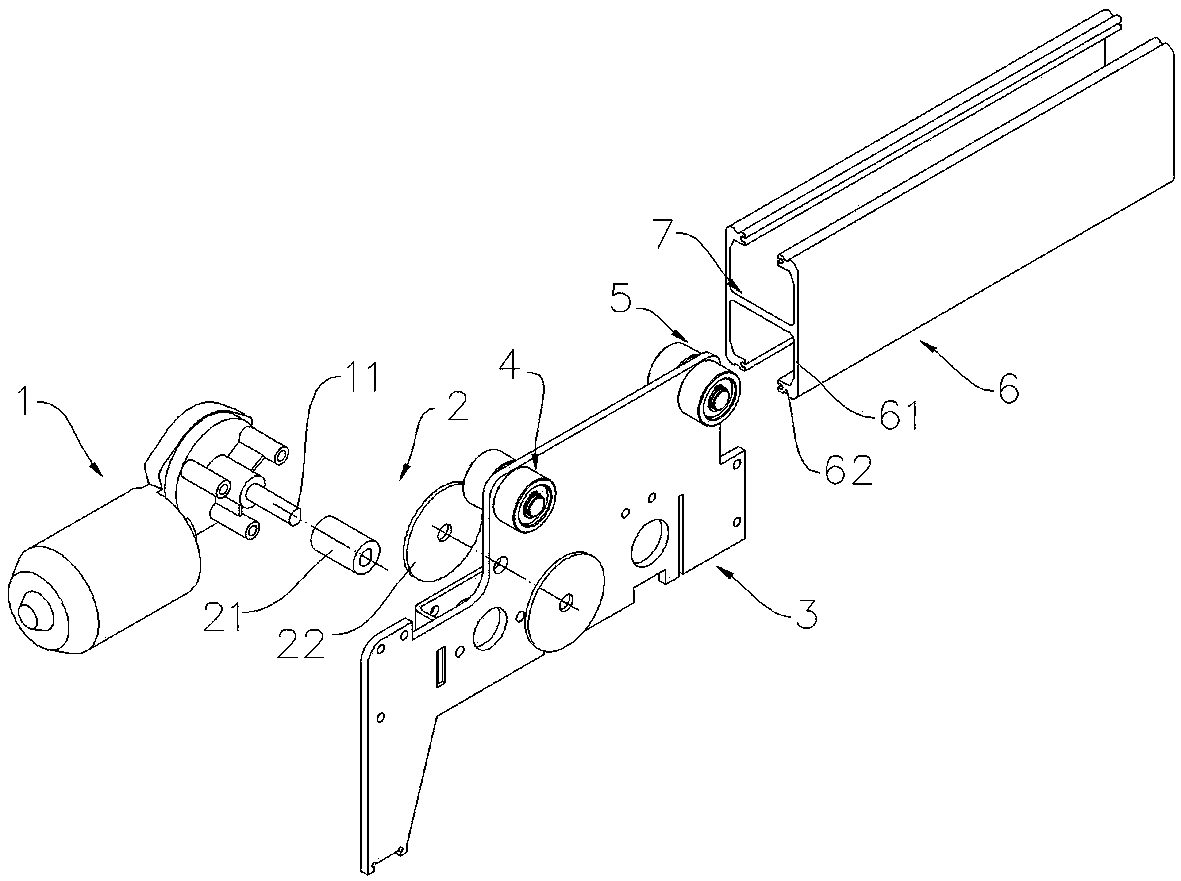

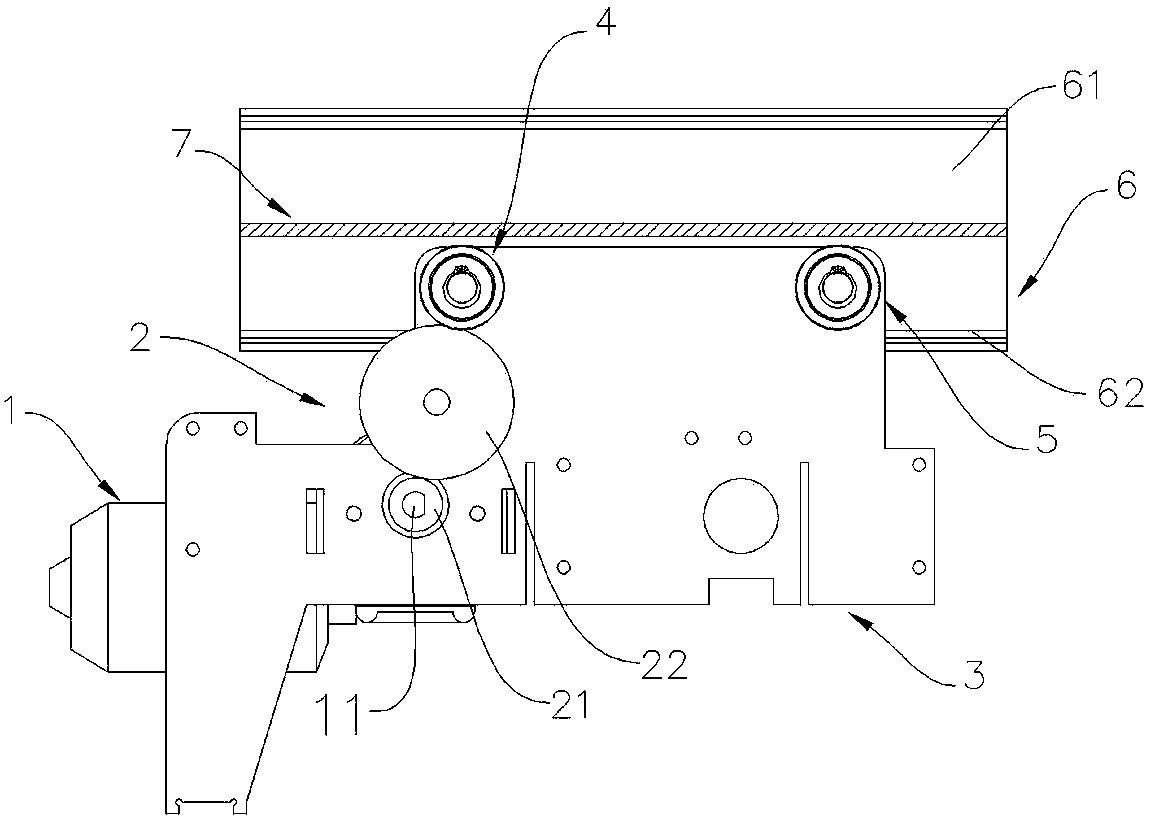

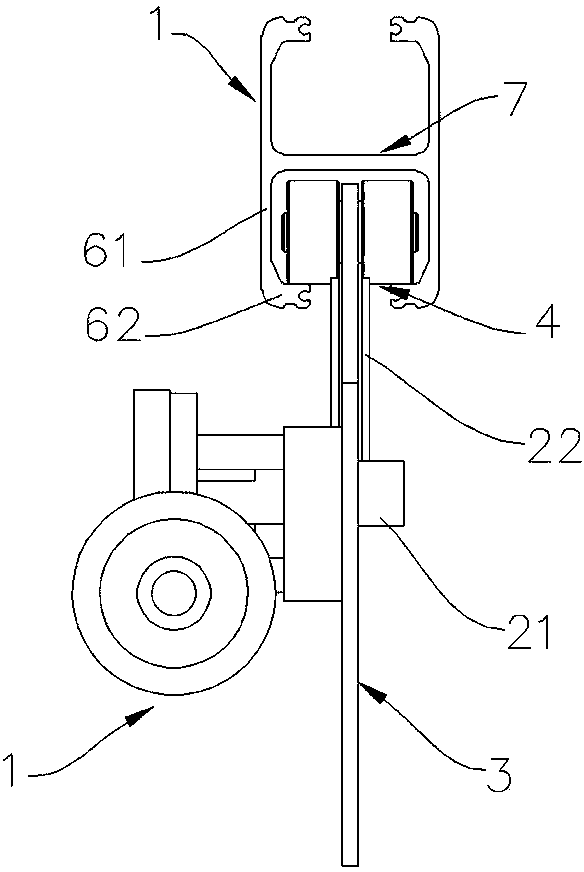

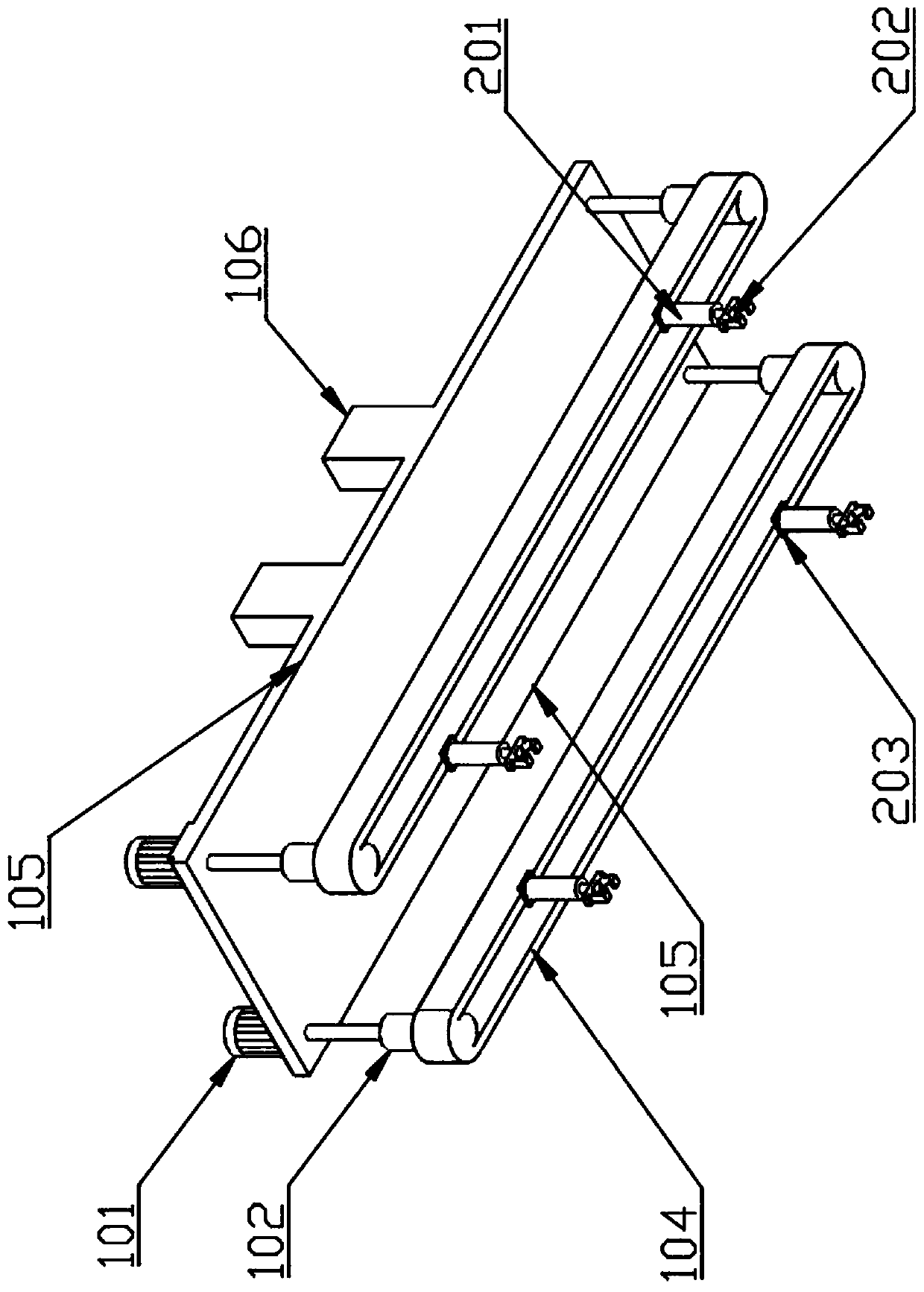

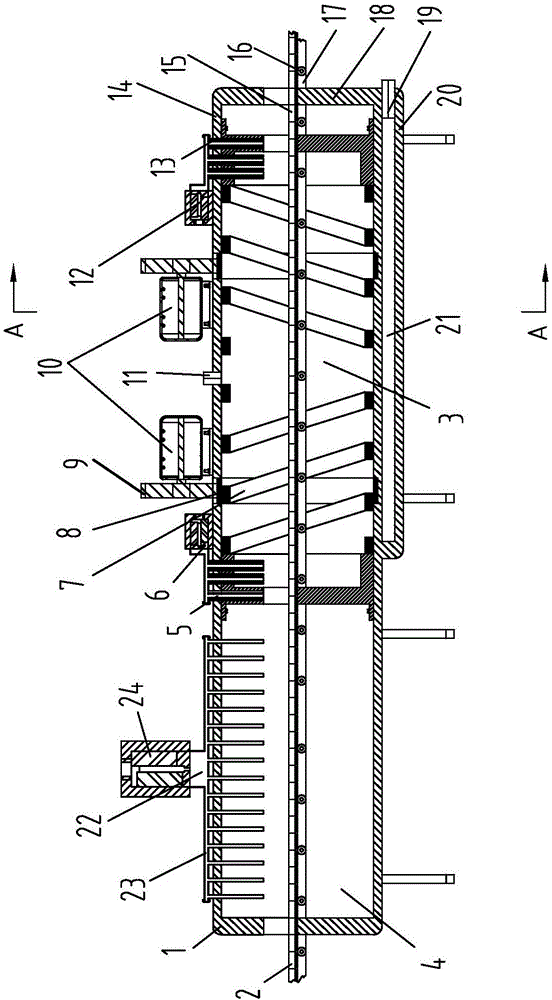

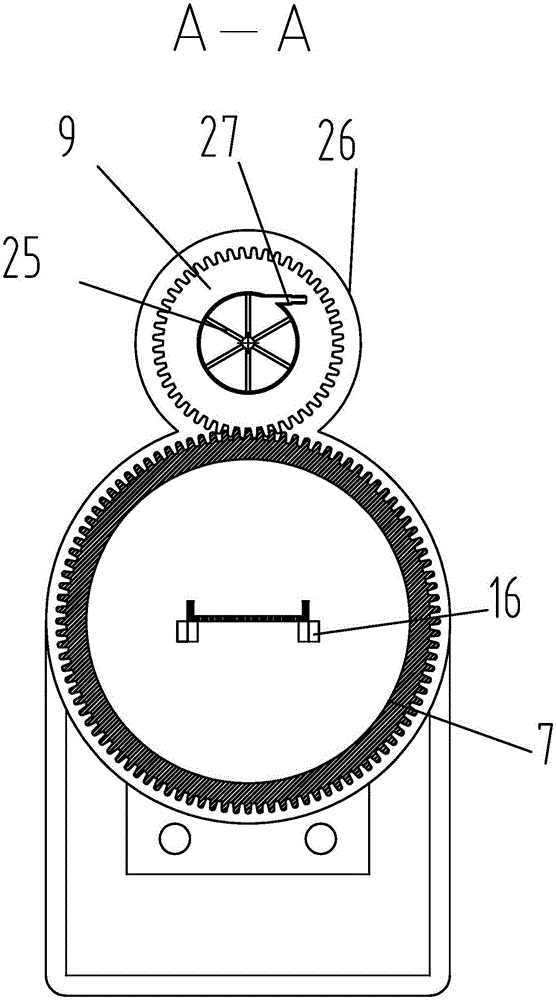

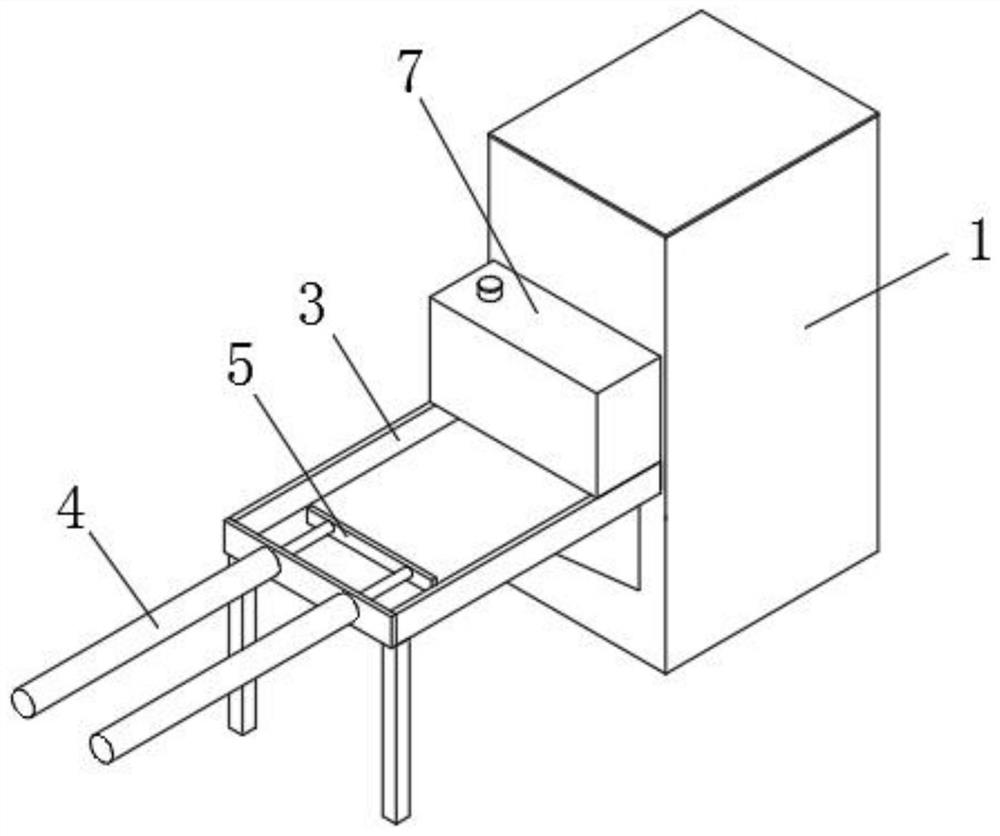

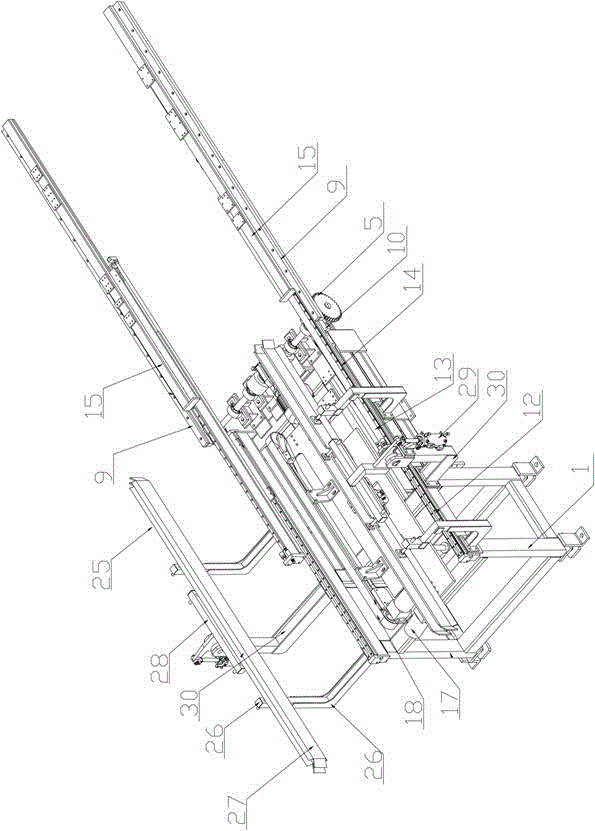

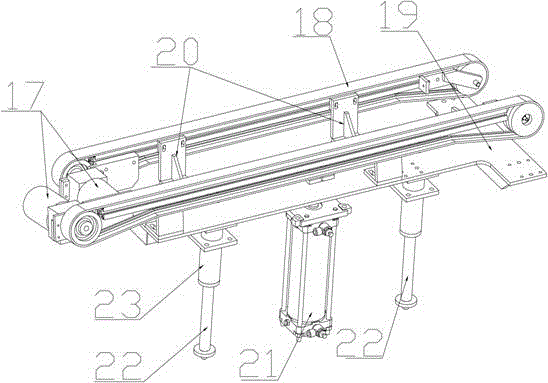

Conveying mechanism of automobile door

ActiveCN103482319AImprove delivery efficiencyKeep shapeConveyor partsMechanical conveyorsDrive shaftCar manufacturing

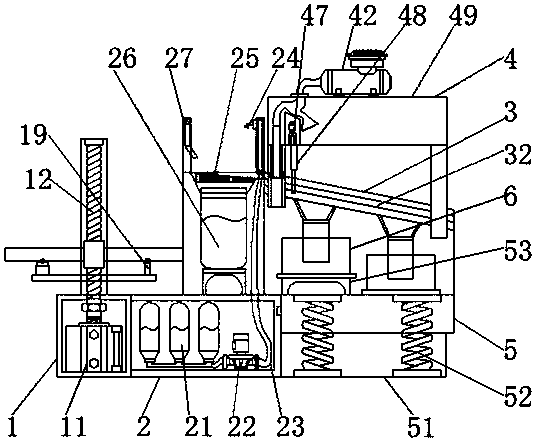

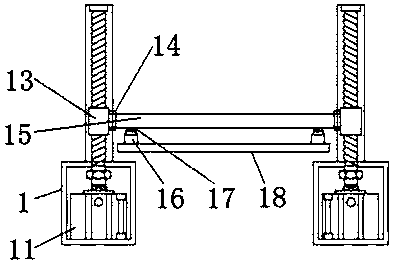

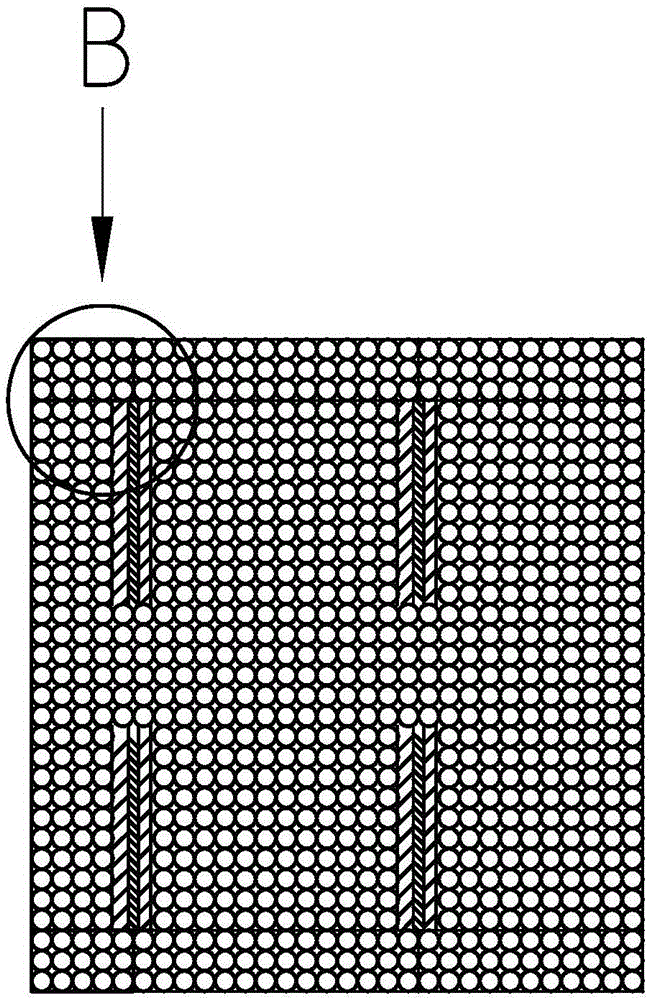

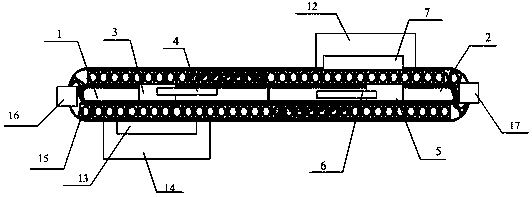

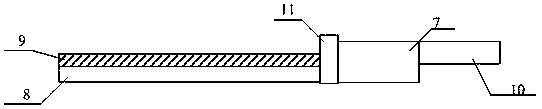

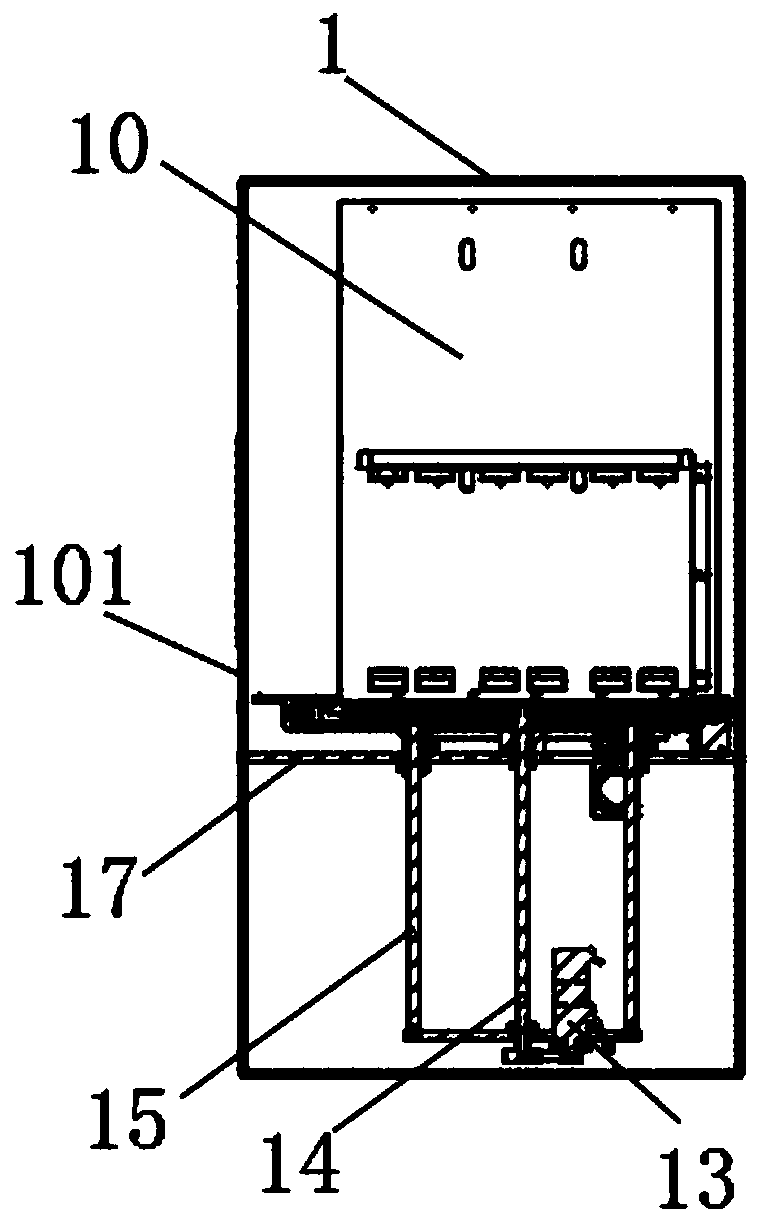

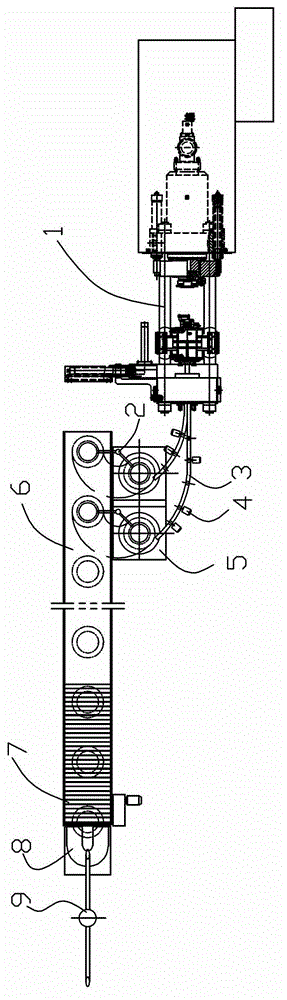

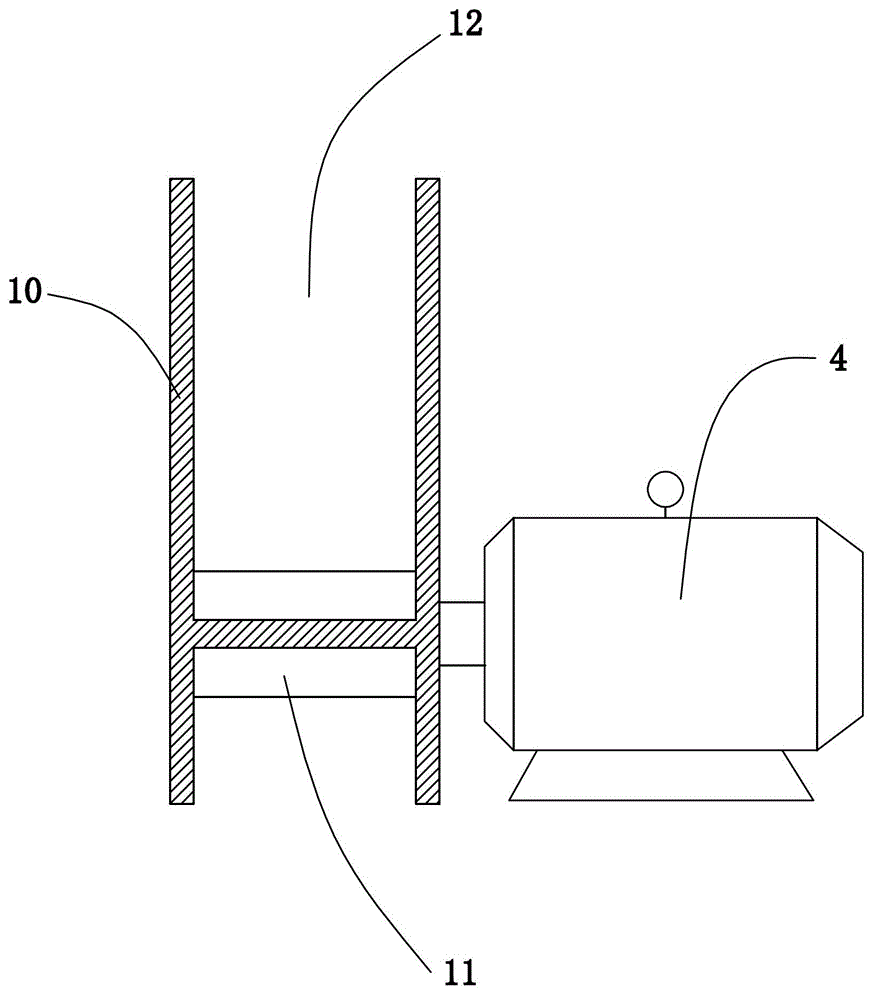

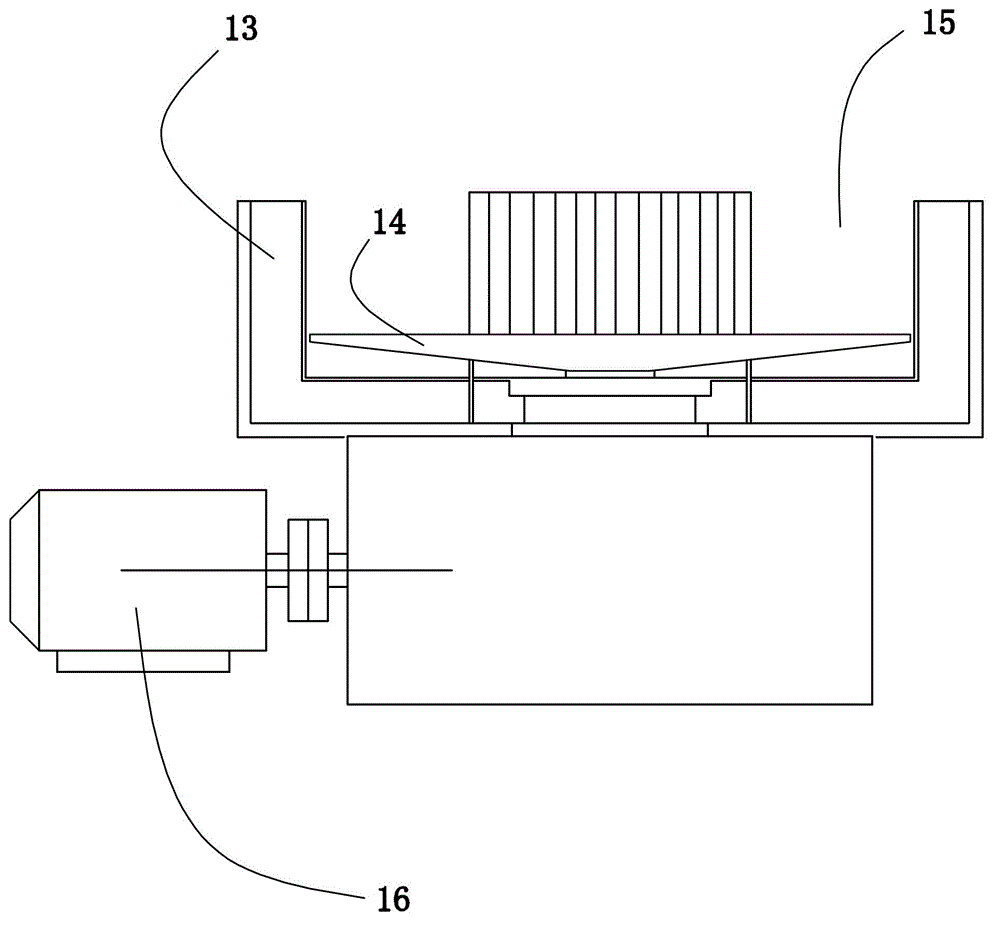

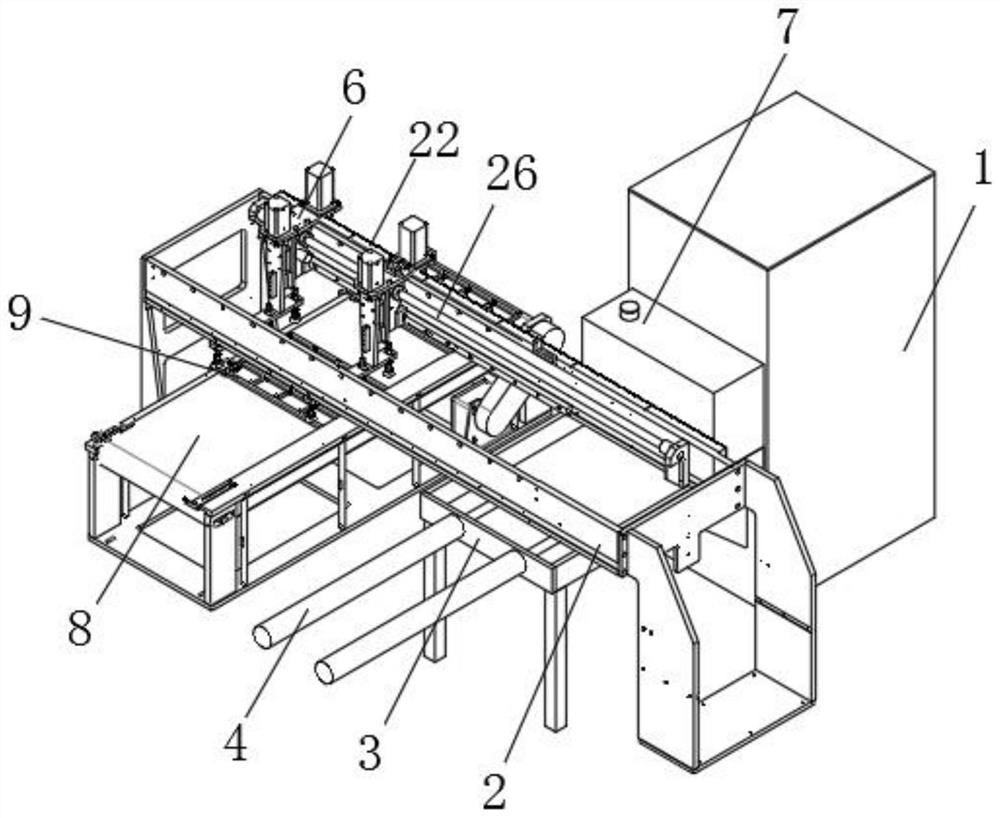

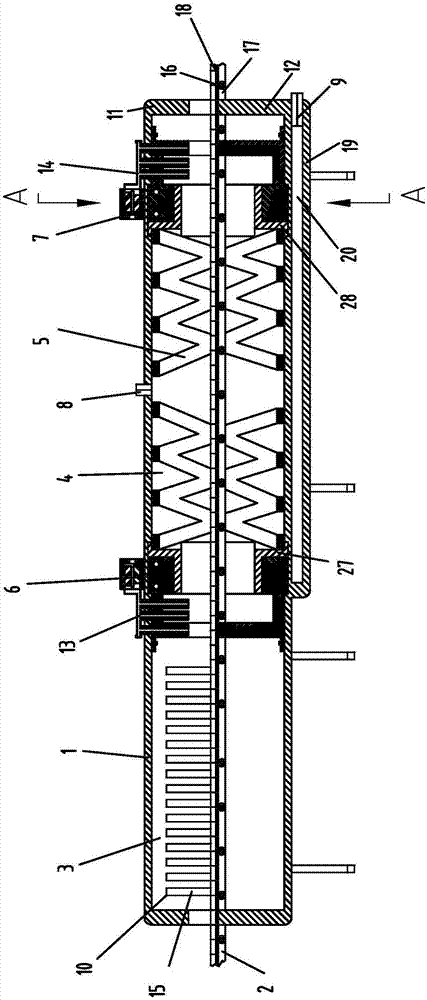

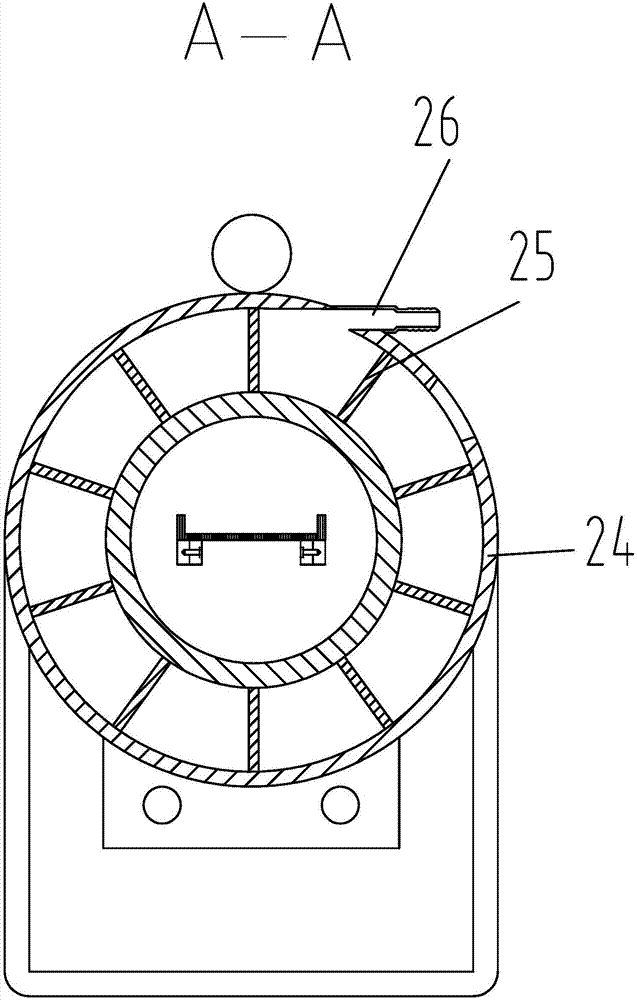

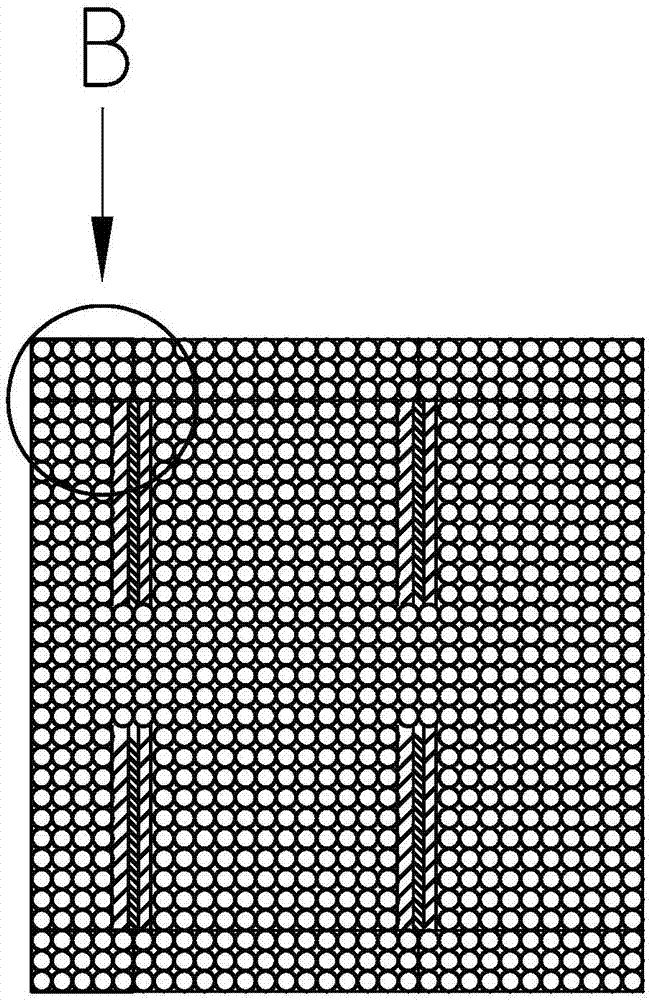

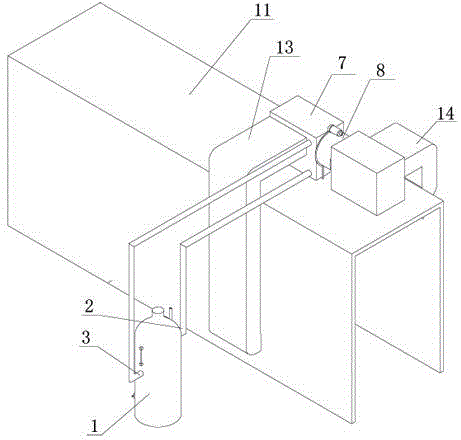

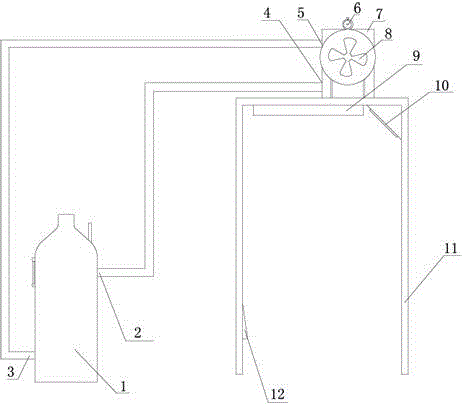

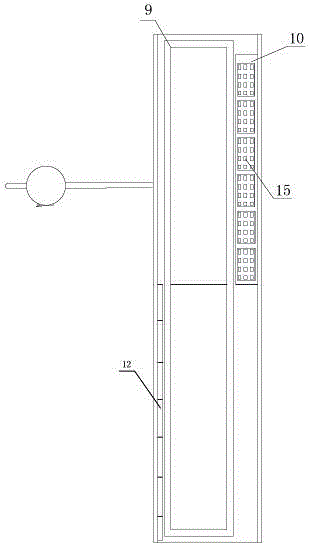

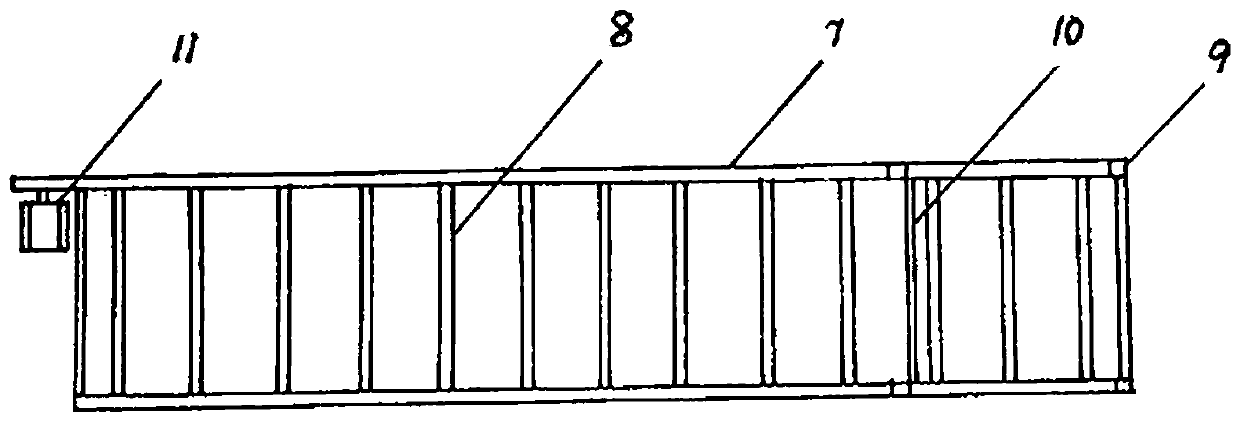

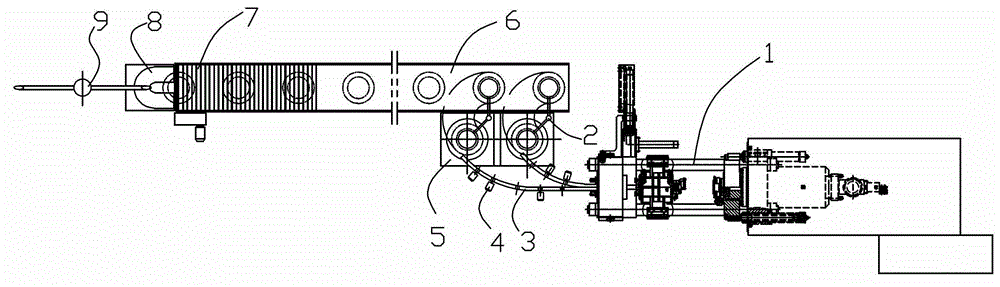

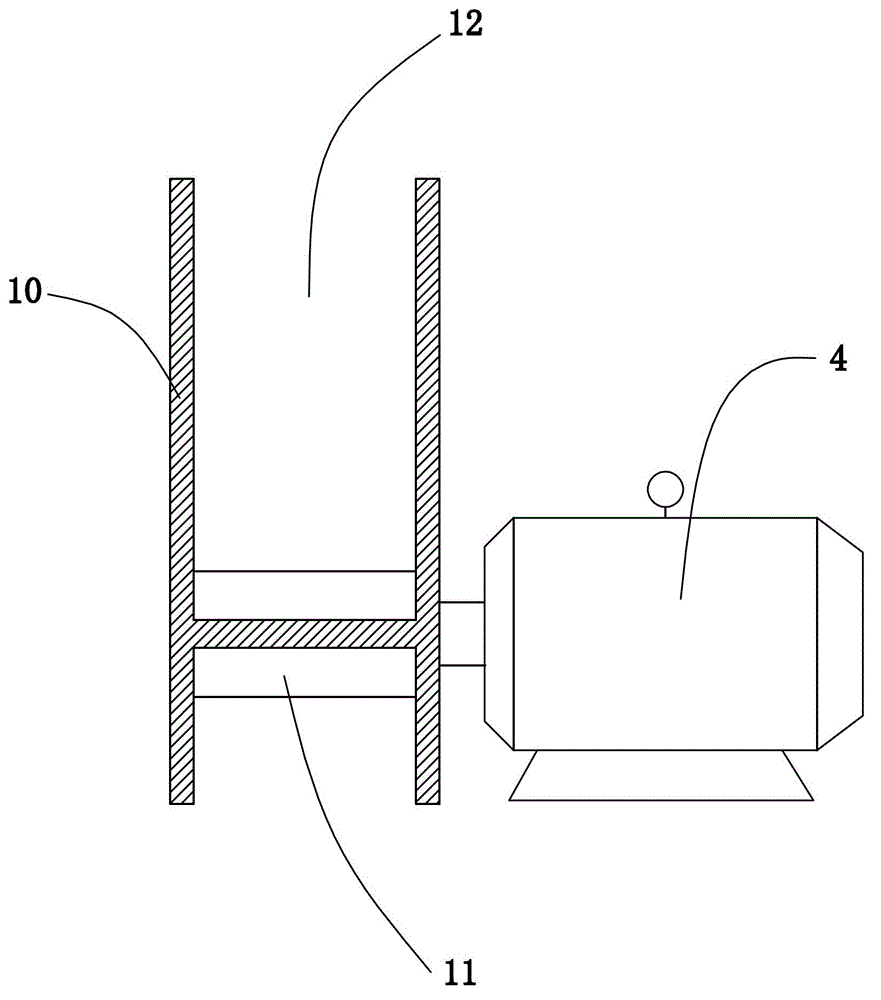

The invention relates to a conveying mechanism of an automobile door and belongs to the technical field of automobile manufacturing. The conveying mechanism of the automobile door comprises an underframe, a delivering mechanism, a transferring mechanism and guiding mechanisms, wherein the delivering mechanism, the transferring mechanism and the guiding mechanisms are arranged on the underframe, a climbing mechanism is arranged on the bottom of the delivering mechanism, the guiding mechanisms are symmetrically arranged on the two sides of the delivering mechanism and are fixed on the underframe, the transfering mechanism comprises a double-layered sliding rail, a motor, transmission shafts, main gears and pinions, the transmission shafts, the main gears and the pinions are arranged on the two ends of the motor respectively, the double-layered sliding rail comprises a lower sliding rail assembly and an upper sliding rail assembly, a first rack is correspondingly arranged above each main gear, a second rack is correspondingly arranged above each pinion, the first racks are meshed with the main gears, the second racks are meshed with the pinions, and the first racks and the second racks are fixedly connected to the upper sliding rail assembly and the lower sliding rail assembly respectively. The conveying mechanism of the automobile door has the advantages that the automation degree is high, the whole conveying process can be achieved stably, safety and reliability are guaranteed, quality of products is guaranteed, labor intensity of workers is relieved, and workpiece conveying efficiency is improved.

Owner:烟台宇信科技有限公司

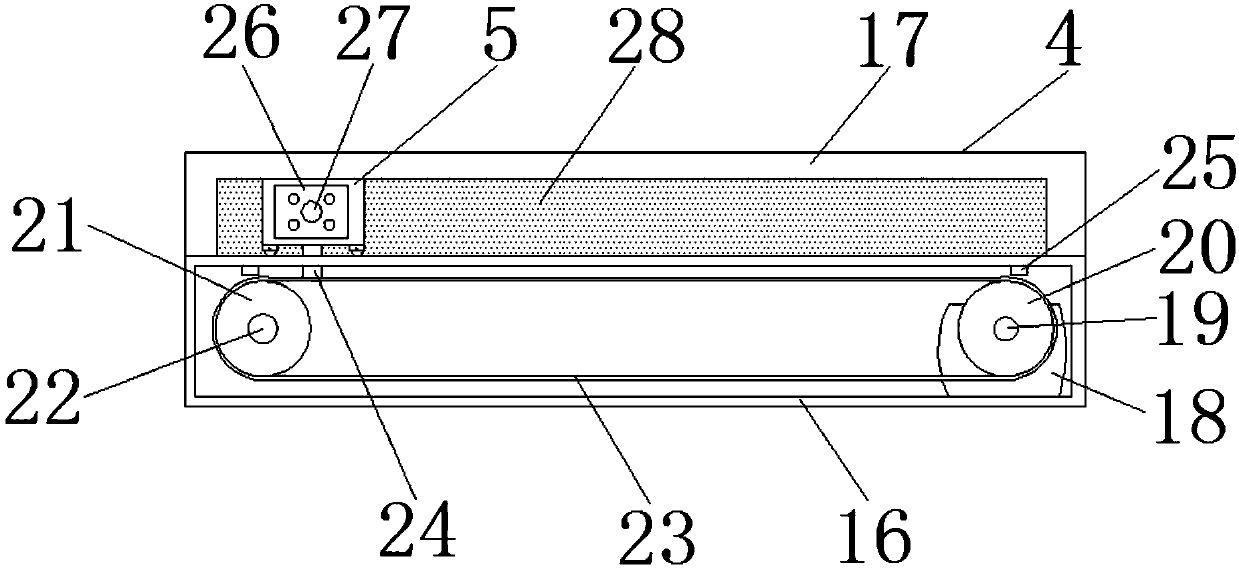

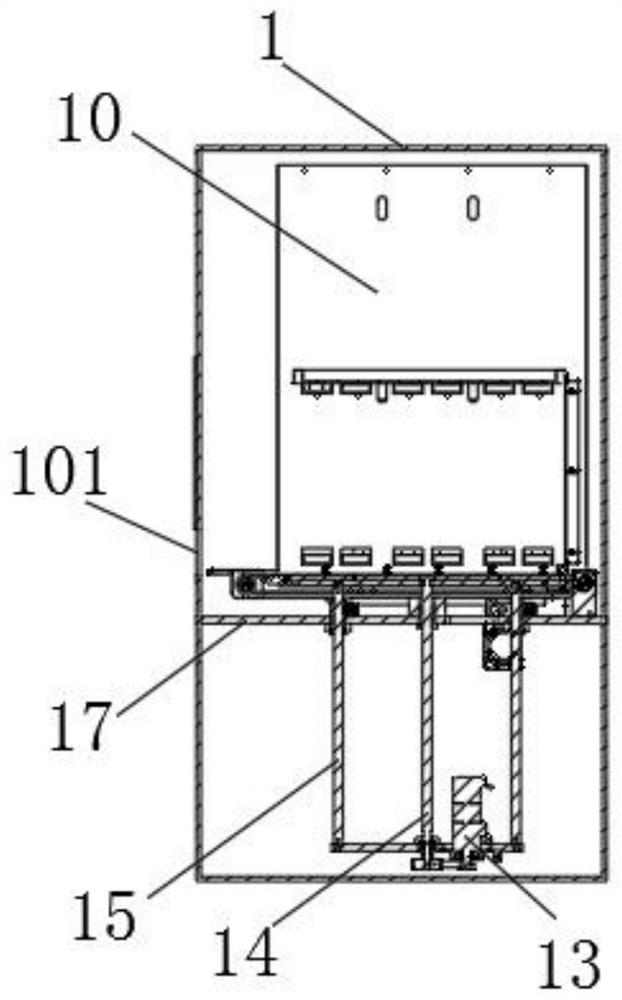

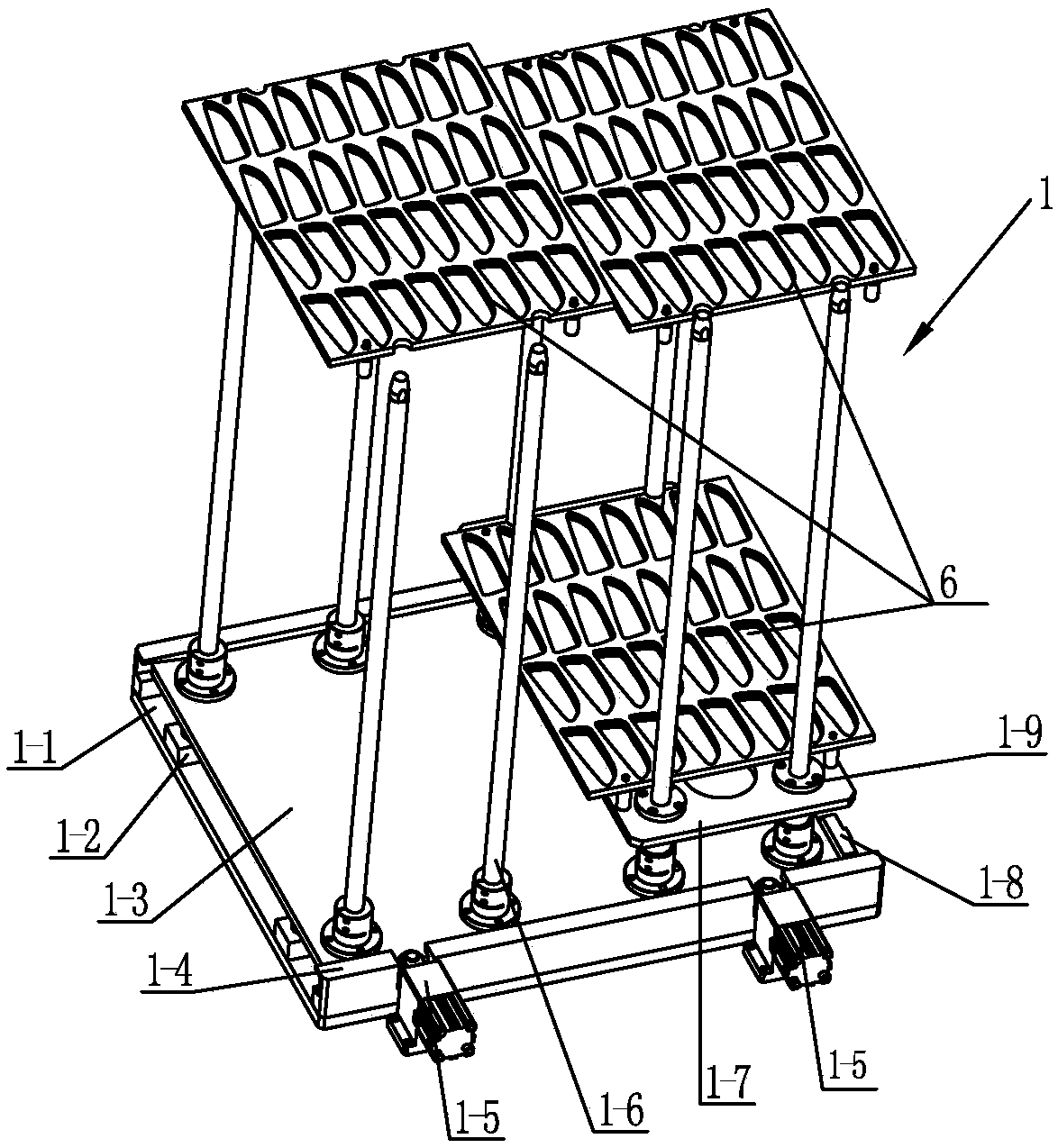

Automatic stacking device for inorganic fireproof expanded perlite heat-insulating boards

InactiveCN105501989AAchieve alignmentRapid succession crawlingStacking articlesDe-stacking articlesStack machineMaterials science

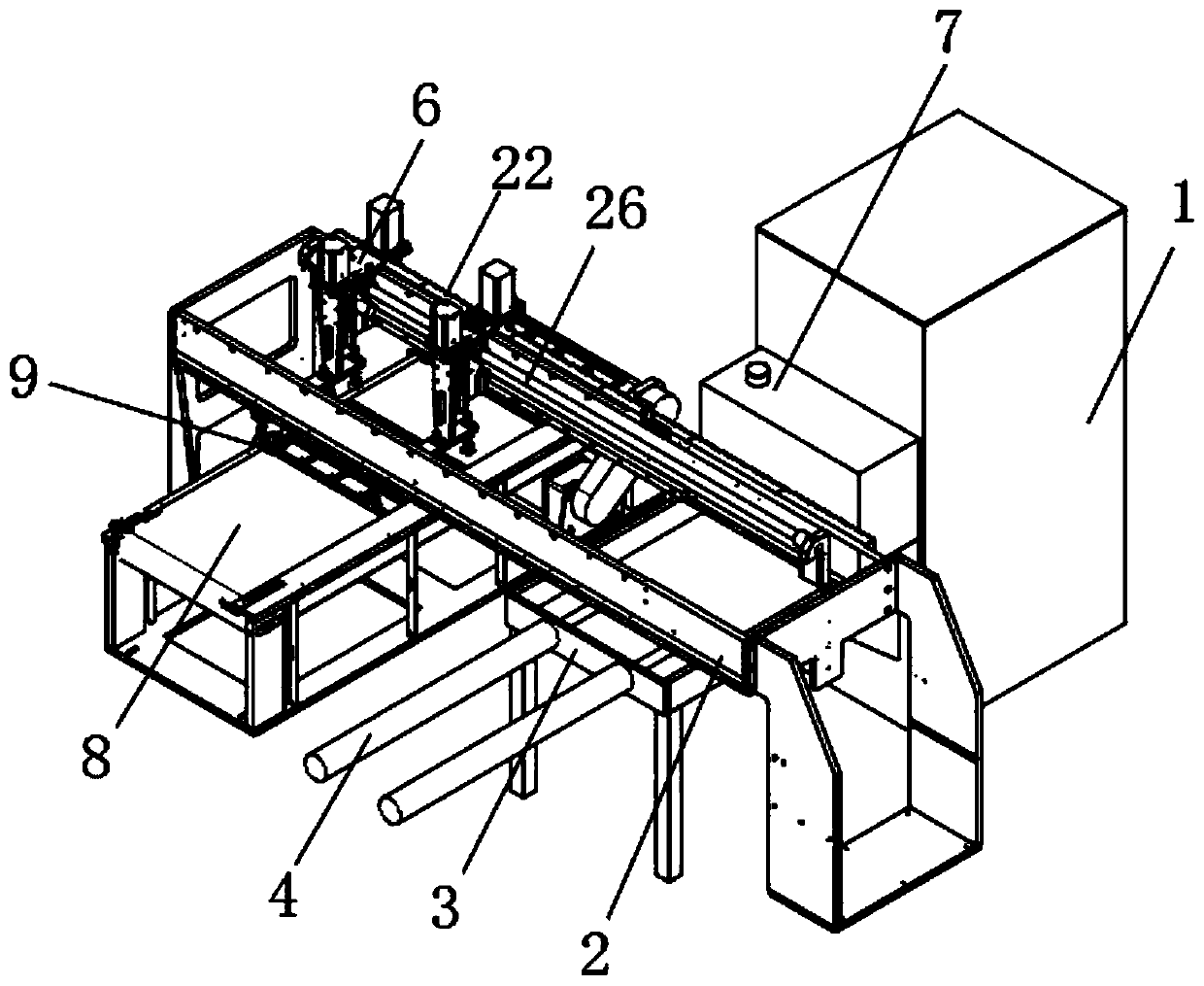

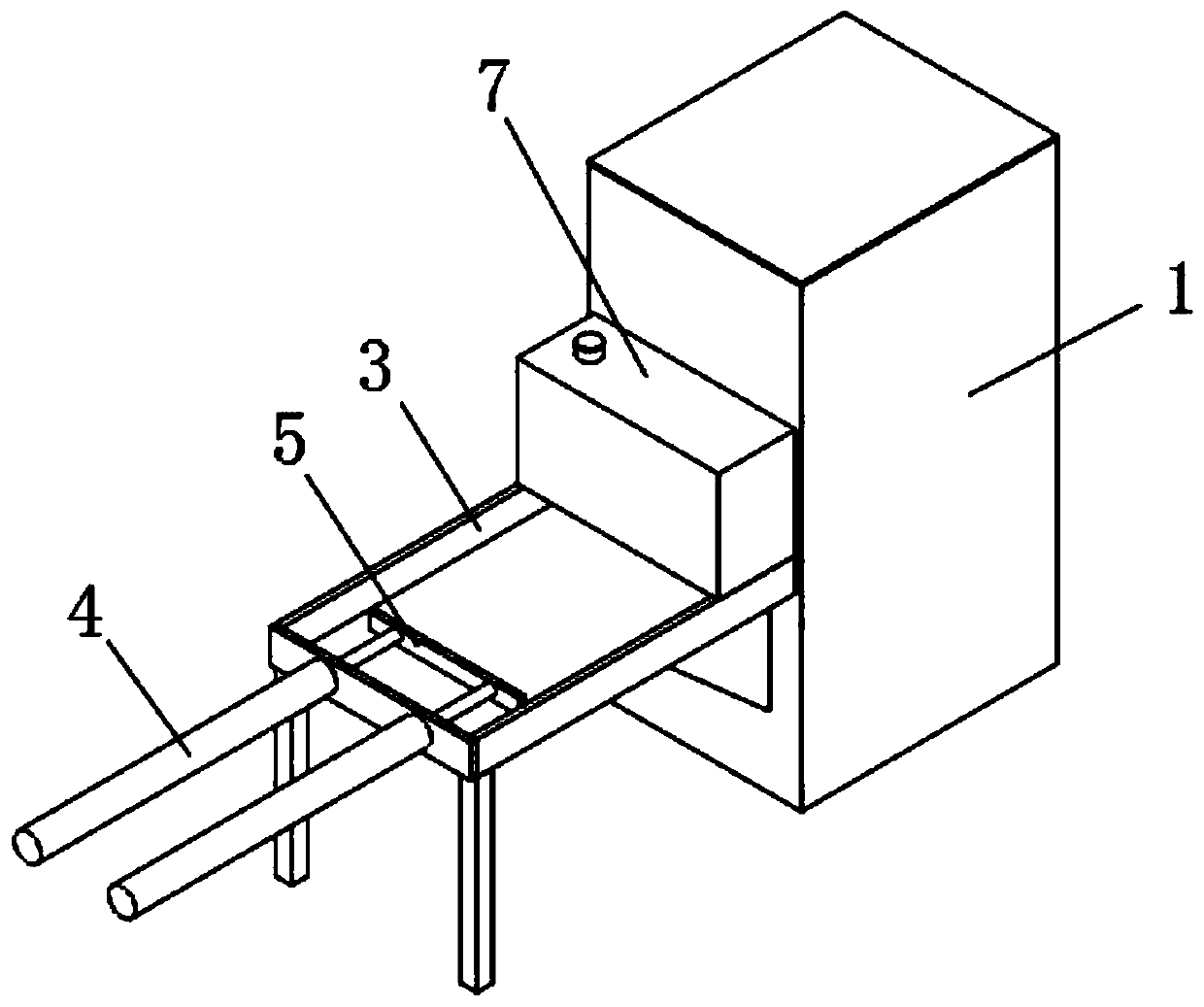

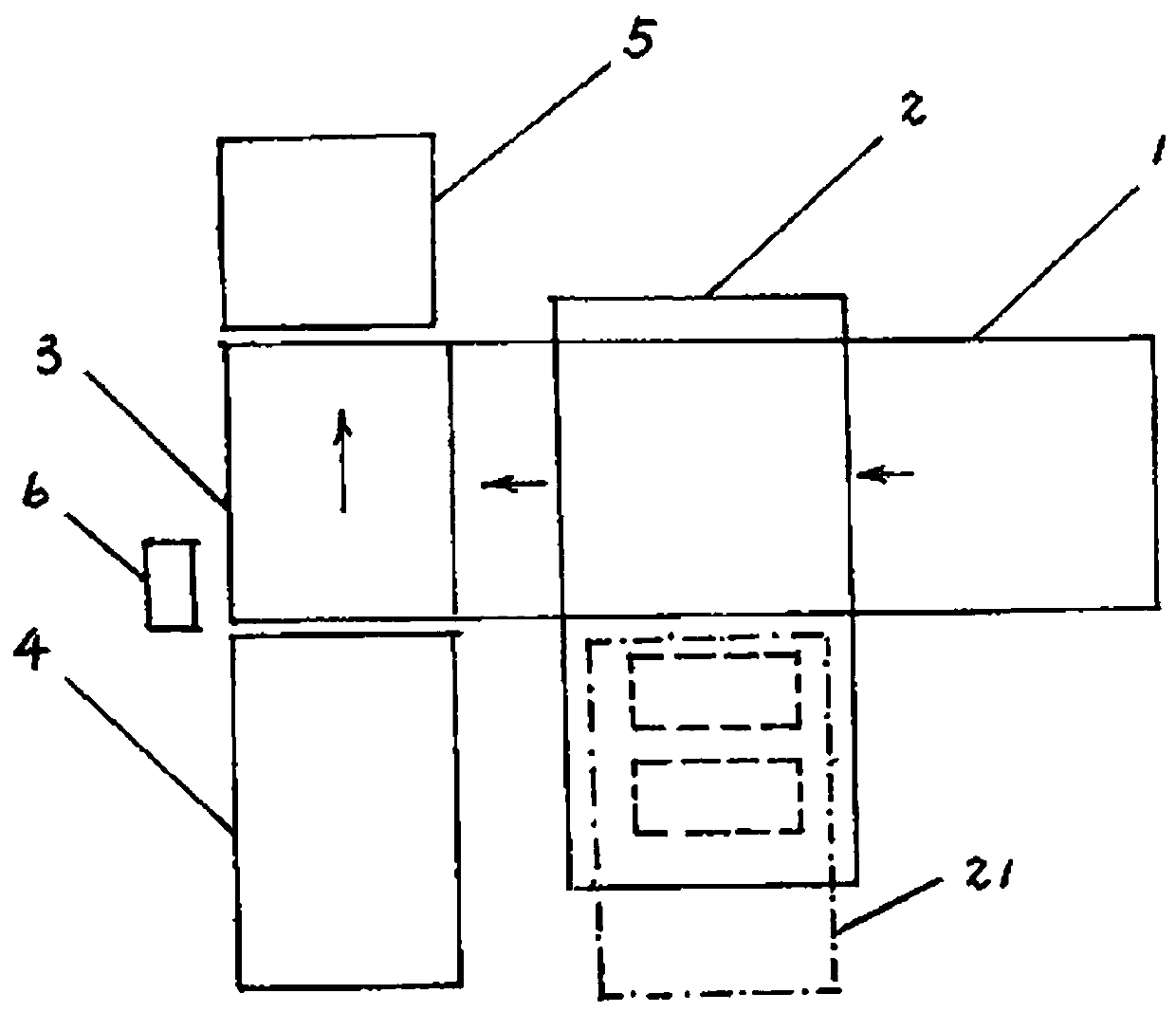

The invention belongs to the technical field of producing inorganic fireproof expanded perlite heat-insulating boards, aims at solving the problem that existing production equipment is low in production efficiency and incapable of realizing continuous packaging and producing of the inorganic fireproof expanded perlite heat-insulating boards and the problem that quality of the heat-insulating boards is affected due to the fact that the heat-insulating boards are prone to collision during carrying and provides an automatic stacking device for the inorganic fireproof expanded perlite heat-insulating boards. The automatic stacking device comprises a pallet feeding roller shaft, a stacking machine, a pallet jacking mechanism, a pallet pushing mechanism, a pallet receiving platform and a control cabinet, the pallet feeding roller shaft is arranged below the stacking machine, a pallet basket is arranged above a feeding end of the pallet feeding roller shaft, the pallet jacking mechanism is arranged below a discharging end of the pallet feeding roller shaft, and the pallet pushing mechanism and the pallet receiving platform (5) are arranged on two sides of the pallet jacking mechanism respectively. Machinery is adopted to replace manpower to automatically loading and stacking pallets, the problem of automatic stacking and loading of the pallets during packaging of the inorganic fireproof expanded perlite heat-insulating boards is solved, and a technical blank in automatic stacking during packaging of the inorganic fireproof expanded perlite heat-insulating boards is filled.

Owner:南通景禾佳信息科技有限公司

Bad fruit sorting device after box opening, for wholesale of agricultural and sideline products

The invention relates to a bad fruit sorting device after box opening, for wholesale of agricultural and sideline products. The bad fruit sorting device comprises a dumping mechanism, a washing mechanism, a sorting mechanism, a detecting mechanism, a shock absorption mechanism and a fruit frame, wherein the washing mechanism is arranged on one side of the dumping mechanism; the sorting mechanism is mounted on the body wall on one side of the washing mechanism; and the detecting mechanism is arranged on the sorting mechanism. According to the bad fruit sorting device disclosed by the invention,the dumping mechanism is arranged, so that after box opening, fruits can be automatically dumped; a fruit box is placed on a placing plate, and a servo motor is started to drive a screw rod to rotate; under the effect of the screw rod, the placing plate is driven by a bevel gear to lift above a bracket frame; an electric telescopic rod is started to push one end of the placing plate to lift; in the lifting course, one end of the placing plate is fixed by a supporting rod, so that the placing plate can be assisted by a rotating shaft to rotate and slope; a rotating shaft is also arranged between the supporting rod and the placing plate, so that the sloping of the placing plate cannot be influenced, fruit boxes are convenient to automatically dump; and fruits in the fruit boxes are poured in the washing mechanism, and manual conveying is not needed.

Owner:芜湖兰易商贸有限公司

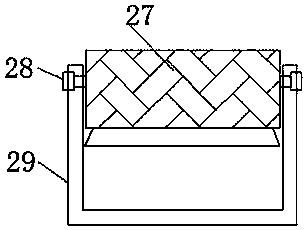

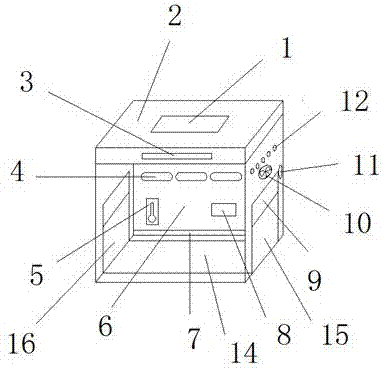

Container for agricultural and sideline product transportation

The invention relates to a container for agricultural and sideline product transportation. The container for the agricultural and sideline product transportation comprises a box, a moving mechanism, an extending mechanism, a damping mechanism, a box door, a heat-preserving layer, heat-preserving sand, a fresh-keeping mechanism and an illuminating mechanism. The moving mechanism is installed belowthe interior of the box, and the extending mechanism is installed above the body wall of one side of the moving mechanism. One side of the extending mechanism is provided with the damping mechanism. The box door is installed at one side of the box. The body wall inside the box is filled with the heat-preserving sand. One side of the fresh-keeping mechanism is provided with the illuminating mechanism. The interior, provided with the box, of the container is provided with the moving mechanism. The moving mechanism can drive a screw rod to be rotated through a servo motor, so a bevel gear drivesthe extending mechanism to be slid under the action of the screw rod, and a cargo at an inlet of the box can be conveyed into the box. A placing position of the cargo is determined by controlling theservo motor to be operated without carrying artificially, and it is not worried that the cargo cannot be loaded by a large-scale machine.

Owner:芜湖兰易商贸有限公司

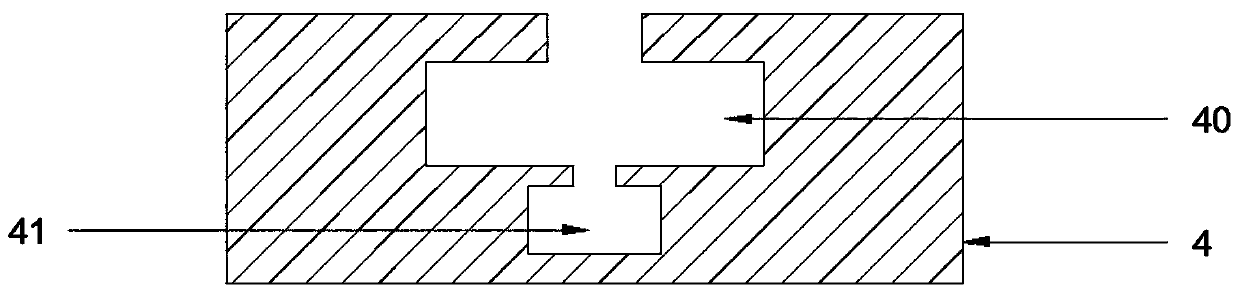

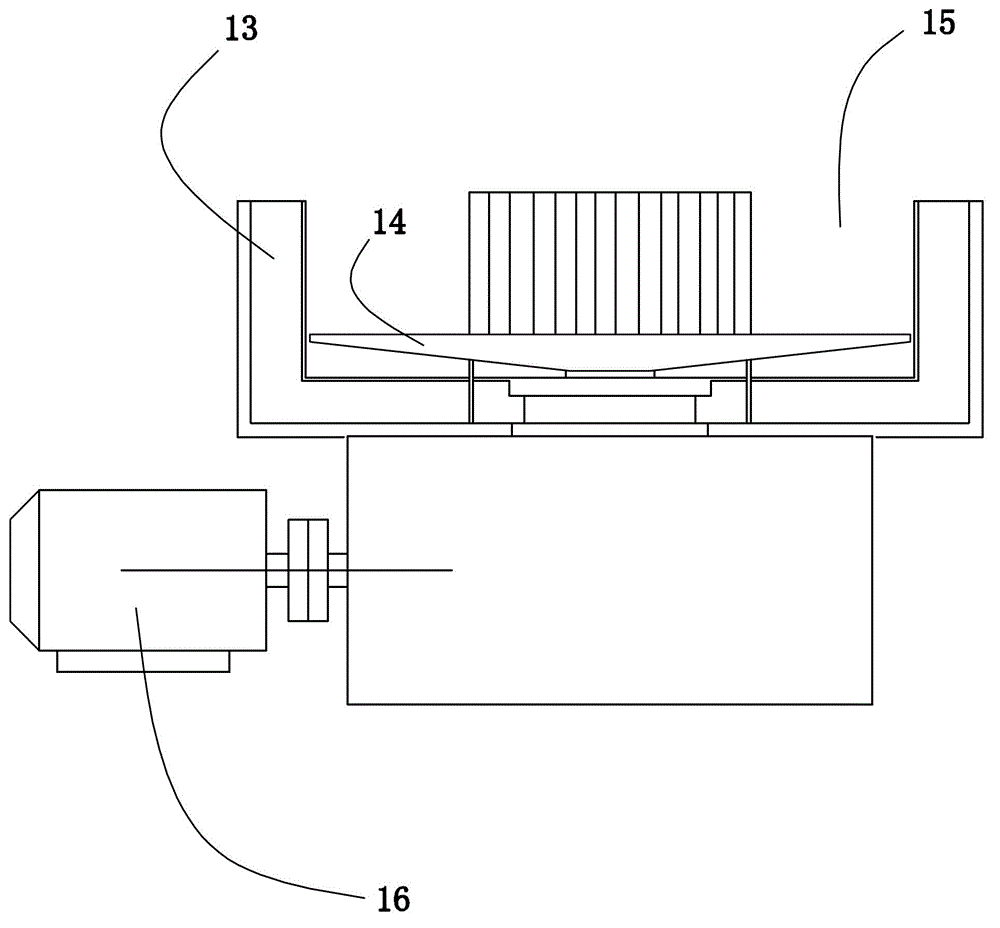

Automatic built-in pneumatic flow-guiding fastener acid-water washing dual-use groove

InactiveCN107309207ANot easy to saveEasy to cleanDrying machines with progressive movementsDrying solid materialsAcid waterAcid washing

The invention provides an automatic built-in pneumatic flow-guiding fastener acid-water washing dual-use groove comprising a shell with openings in the two ends and a conveyer belt arranged in the shell. The shell is sequentially provided with an acid washing groove body, a water washing groove body and a drying groove body. The acid washing groove body and the water washing groove body are internally provided with roll frames correspondingly, the tops of the acid washing groove body and the water washing groove body are provided with water inlets correspondingly, and the bottoms of the acid washing groove body and the water washing groove body are provided with water outlets correspondingly. A heating device is arranged on the drying groove body, and openings for allowing the conveyer belt to pass through are formed between the acid washing groove body and the water washing groove body as well as between the water washing groove body and the drying groove body correspondingly. The conveyer belt is horizontally arranged, passes through the shell, penetrates through the openings of the two ends of the shell and extends out of the shell, and a plurality of baffles perpendicular to the conveyer belt are arranged on the conveyer belt at equal intervals. According to the automatic built-in pneumatic flow-guiding fastener acid-water washing dual-use groove, the functions are diversified, washing and drying can be synchronously conducted, the washing effect is good, the one-time cleaning quantity is large, continuous operation can be achieved, the labor force is saved, and meanwhile the washing efficiency is greatly improved.

Owner:NINGBO CITY YINZHOU FENGMING IND PROD DESIGN

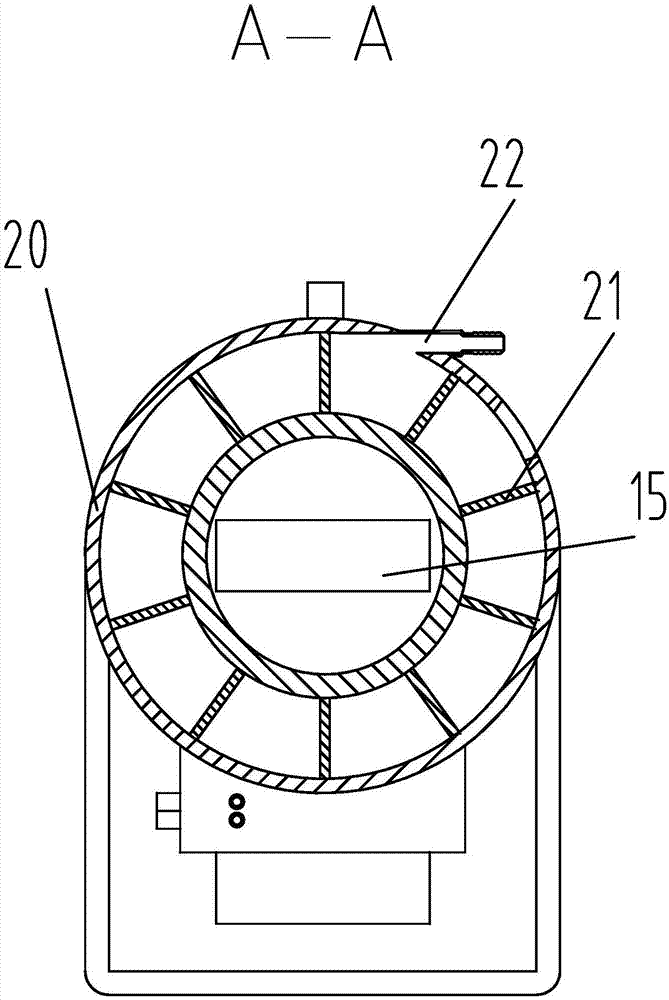

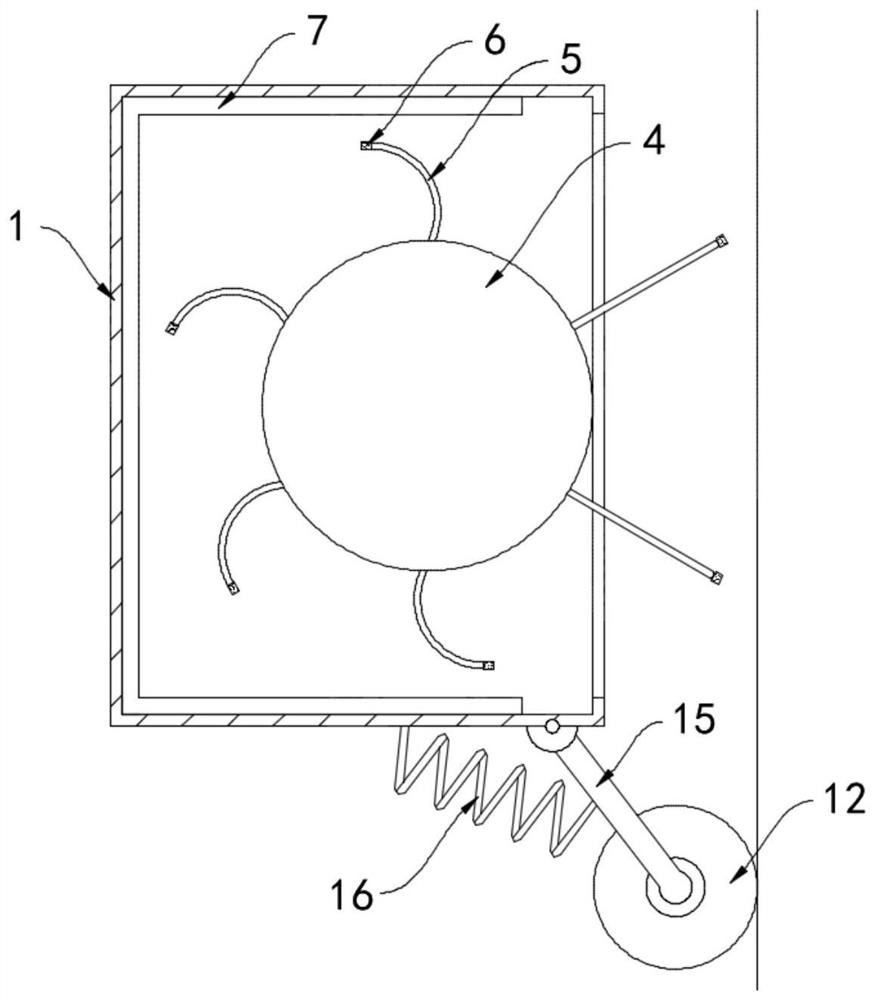

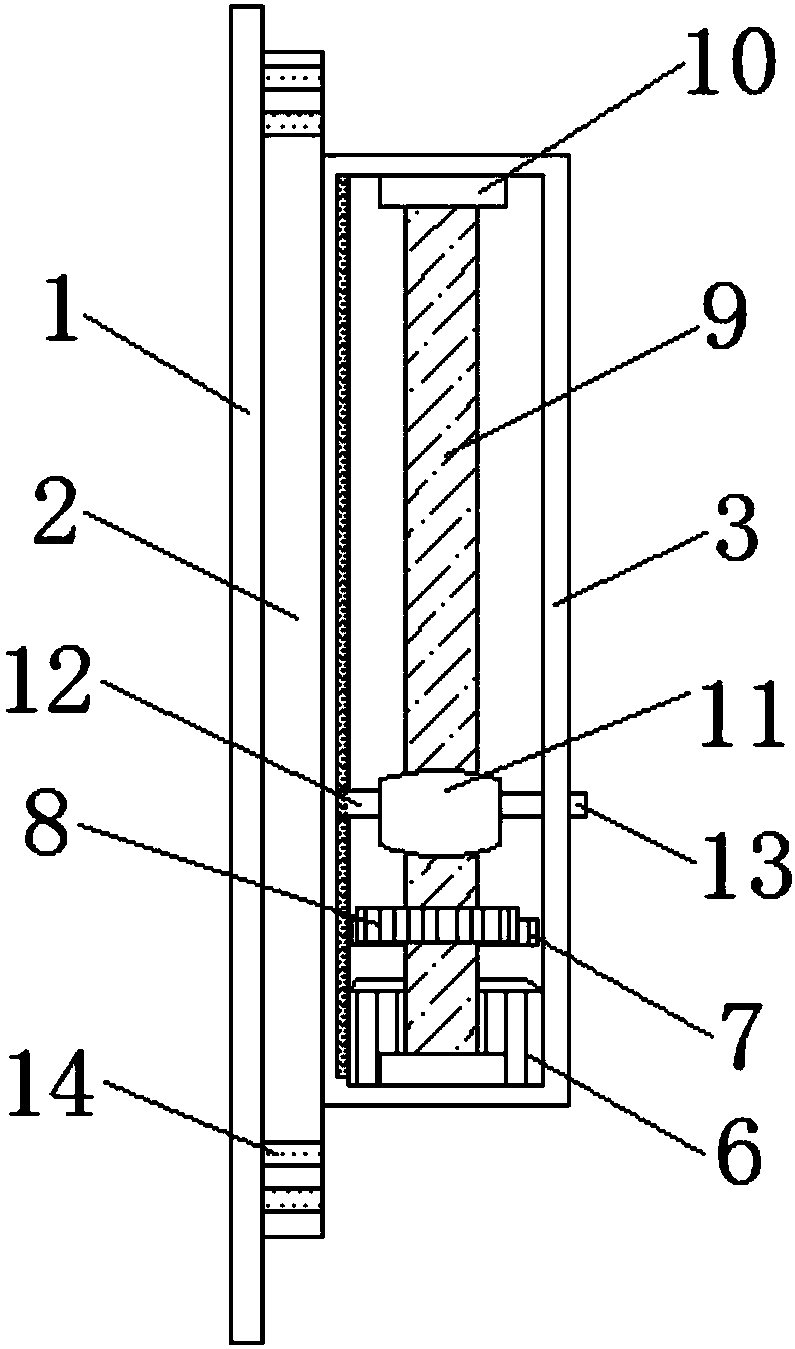

Automatic wall coating device for building construction

InactiveCN111719827AApply evenlyNot easy to dropBuilding constructionsGear wheelArchitectural engineering

The invention belongs to the field of building construction equipment, and particularly relates to an automatic wall coating device for building construction. The automatic wall coating device comprises a housing and a rail rod, wherein the rail rod penetrates through the housing; a toothed slot is formed in the side wall of the rail rod; the lower end of the housing fixedly communicates with a charge tube; a rotary roller is rotatably arranged in the housing; a plurality of bearing plates which are arranged in the form of a ring-shaped array are arranged on the peripheral side wall of the rotary roller; the bearing plates are rubber elastic plates; ends, away from one another, of the bearing plates are equipped with permanent magnetic stripes; permanent magnet pieces which are repellent to same electrodes of the permanent magnetic stripes are arranged on the side wall of the housing; a motor is mounted on the side wall of the housing; the rotary roller is fixedly and coaxially connected to the output shaft of the motor; the other end of the rotary roller is coaxially and fixedly equipped with a gear; and the gear is engaged with a rail rod. The housing slowly moves upwards along awall body, so that cement is uniformly coated onto a wall surface, and a cement layer is coated uniformly and flatly. Moreover, the automatic wall coating device is safe and reliable, and greatly improves work efficiency.

Owner:肖永永

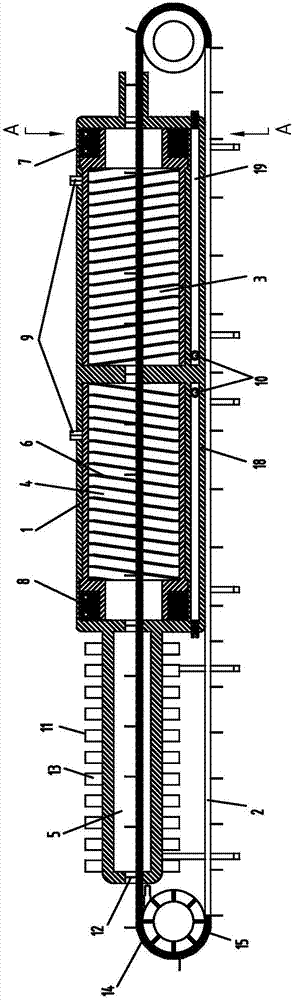

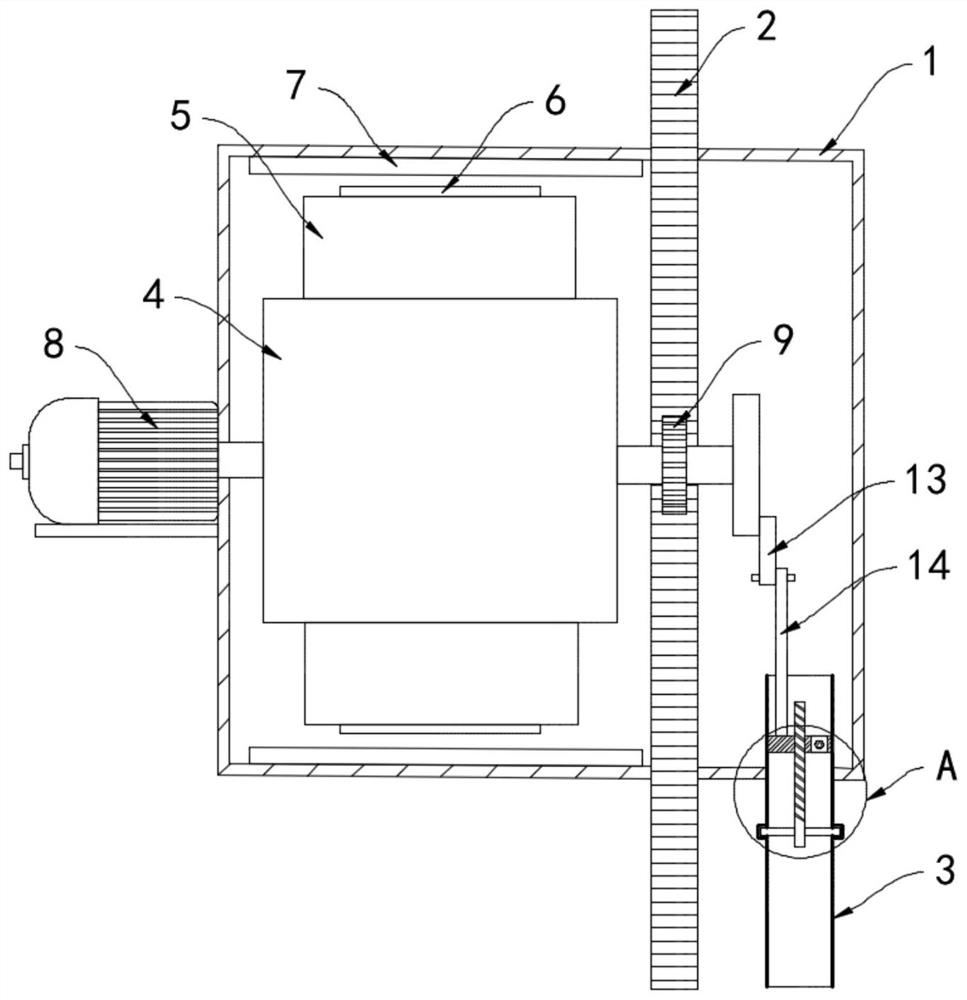

Full-hydraulic underground drill rig translation device

InactiveCN106639872AEasy to moveAchieve freedom of movementDerricks/mastsDrilling machines and methodsHydraulic cylinderUnderground tunnel

The invention provides a full-hydraulic underground drill rig translation device which comprises a support frame. The support frame is a rectangular support, and the four corners of the support frame are each provided with a hydraulic supporting device; two longitudinal hydraulic cylinders are oppositely arranged on the inner sides of the two short edges of the support frame and fixedly connected to the two opposite edges of a connecting part, two transverse hydraulic cylinders are oppositely arranged on the inner sides of the two long edges of the support frame and fixedly connected to the two opposite edges of the connecting part, a rotating disc is arranged on the top of the connecting part, a drill rig platform is arranged on the top of the rotating disc, a plurality of drill rig fixing grooves are formed in the upper surface of the drill rig platform, a balance sensor is arranged at the center of the bottom of the connecting part and connected with all the hydraulic supporting devices through connecting wires, and a plurality of universal wheels are arranged at the bottom of the support frame. According to the full-hydraulic underground drill rig translation device, a drill rig can move in an underground tunnel more conveniently, free moving of the drill rig in the narrow underground tunnel is achieved, manual carrying is not needed, manpower and material resources are greatly saved, and the construction safety is improved.

Owner:TIANJIN TONGXIN COAL MINE MACHINE MFR

Suspension device

Owner:TAICANG KANGHUI TECH DEV

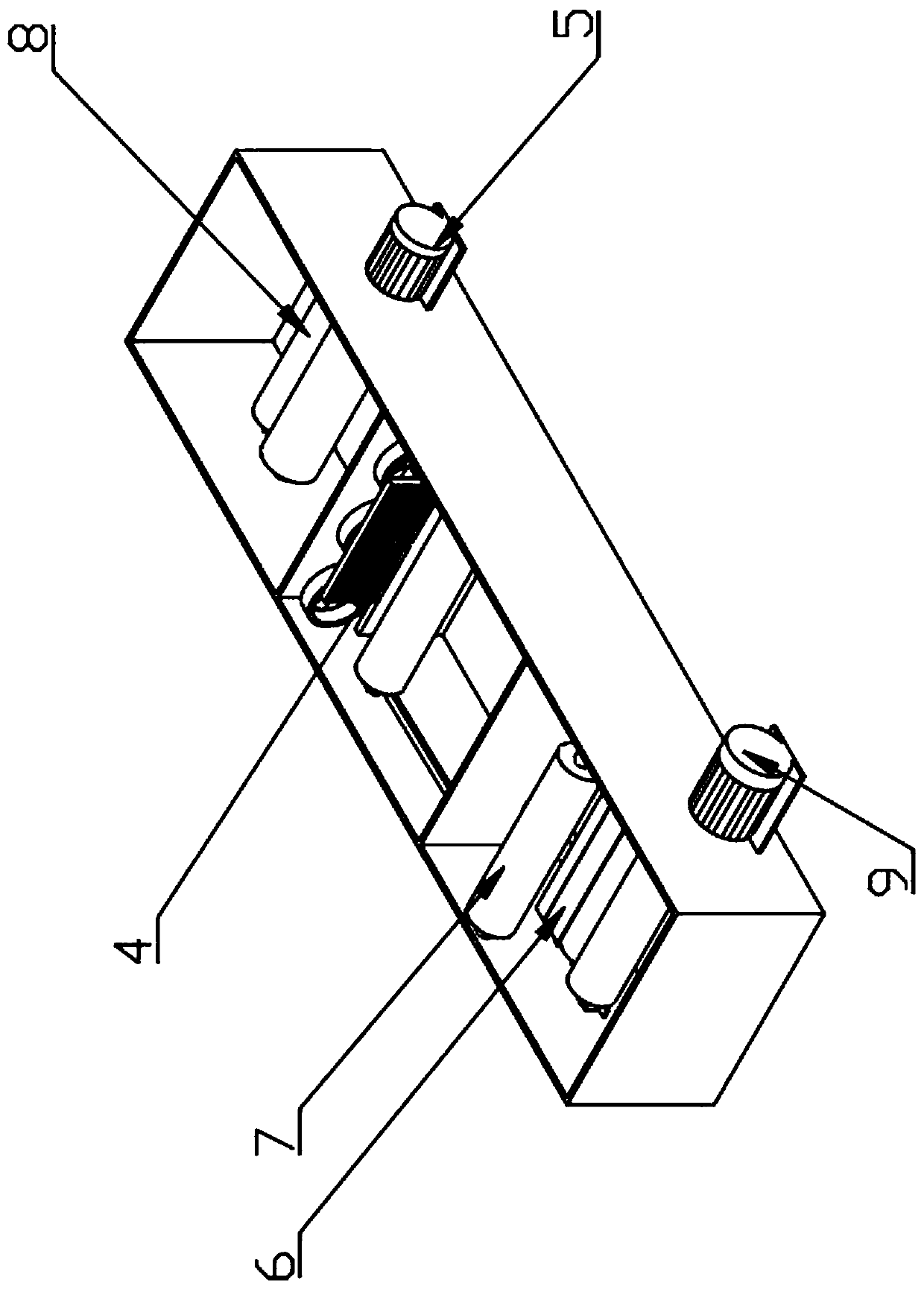

Use-conveniently false twister adjusting structure

InactiveCN107858772AHeight adjustableAchieve regulationContinuous wound-up machinesMotor driveEngineering

The invention provides an easy-to-use adjusting structure of a false twister and relates to the technical field of textile machinery. The easy-to-use false twister adjustment structure includes a wall board, a fixed board and a board box, the side wall of the fixed board is welded to the board box, and a fixing hole is opened inside the fixed board, and the fixed board is fixed through the The bolts in the holes are fixedly connected to the wallboard, the side of the board box far away from the fixed board is connected with an adjustment piece, and the bottom of the inner wall of the board box is fixedly installed with a lifting motor. The easy-to-use false twister adjustment structure drives the rotation of the driving gear through the lifting motor, the rotation of the transmission gear drives the rotation of the screw, and drives the turbine screwed with the screw to move up and down on the outer surface of the screw, and is driven by the connecting rod. The false twister moves up and down to adjust the height of the false twister without moving the wallboard to fix the wallboard at the upper and lower positions of the winding frame, which reduces labor intensity and improves work efficiency.

Owner:新昌县城关宾立机械厂

Rubber roller cleaning and laminating device

InactiveCN110394324ANo manual handlingImprove efficiencyDrying gas arrangementsCleaning using toolsEngineeringMechanical engineering

Owner:安徽兰翔纺机科技有限公司

Acid pickling and cleaning tank for pneumatic flow-guiding automatic fasteners

InactiveCN107433269ANot easy to saveFully cleanedDrying gas arrangementsCleaning using liquidsSpiral bladeFastener

The invention provides an acid pickling and cleaning tank for pneumatic flow-guiding automatic fasteners. The acid pickling and cleaning tank for the pneumatic flow-guiding automatic fasteners comprises a shell and a conveying belt, wherein the shell is provided with openings at the two ends, and the conveying belt is arranged in the shell; the shell is provided as a cleaning tank and a drying tank, a single spiral blade rolling frame is arranged in the cleaning tank, the roller frame is powered by a pneumatic device arranged out of the shell, a water inlet is formed in the top of the cleaning tank, and a water outlet is formed in the bottom of the cleaning tank; gas sealing mechanisms are correspondingly arranged at the two openings in the cleaning tank, an air blowing device is arranged in the drying tank, and an opening for passing of the conveying belt is formed between the cleaning tank and the drying tank; and the conveying belt is horizontally arranged through the shell, and penetrates through the openings at the two ends of the shell and extends out of the shell. The acid pickling and cleaning tank for the pneumatic flow-guiding automatic fasteners has various functions, cleaning and drying can be conducted simultaneously, the cleaning effect is good, one-time cleaning quantity is large, continuous running is achieved, and cleaning efficiency is improved significantly.

Owner:NINGBO CITY YINZHOU FENGMING IND PROD DESIGN

Bicycle tire production line

The invention discloses a bicycle tire production line. The bicycle tire production line comprises a first production mechanism, a second production mechanism, a transmission chain, a mold and a fixedtemplate. The first production mechanism comprises a first manipulator base, a first robot arm, a second centrifuge, a second baffle and a bristle brush. The second production mechanism comprises a second manipulator base, a second robot arm, a centrifuge, a baffle and a second bristle brush. The bicycle tire production line adds the centrifuge, and a supporting frame is mounted on the upper partof the centrifuge to suspend starting tools and release agent trachea conveniently, and the bristle brush is installed in a track to facilitate removal of debris in the track, and two production lines alternately produce. Production speed is higher, and degree of automation is high, and no human carrying is needed.

Owner:和聚诚智能科技(太仓)有限公司

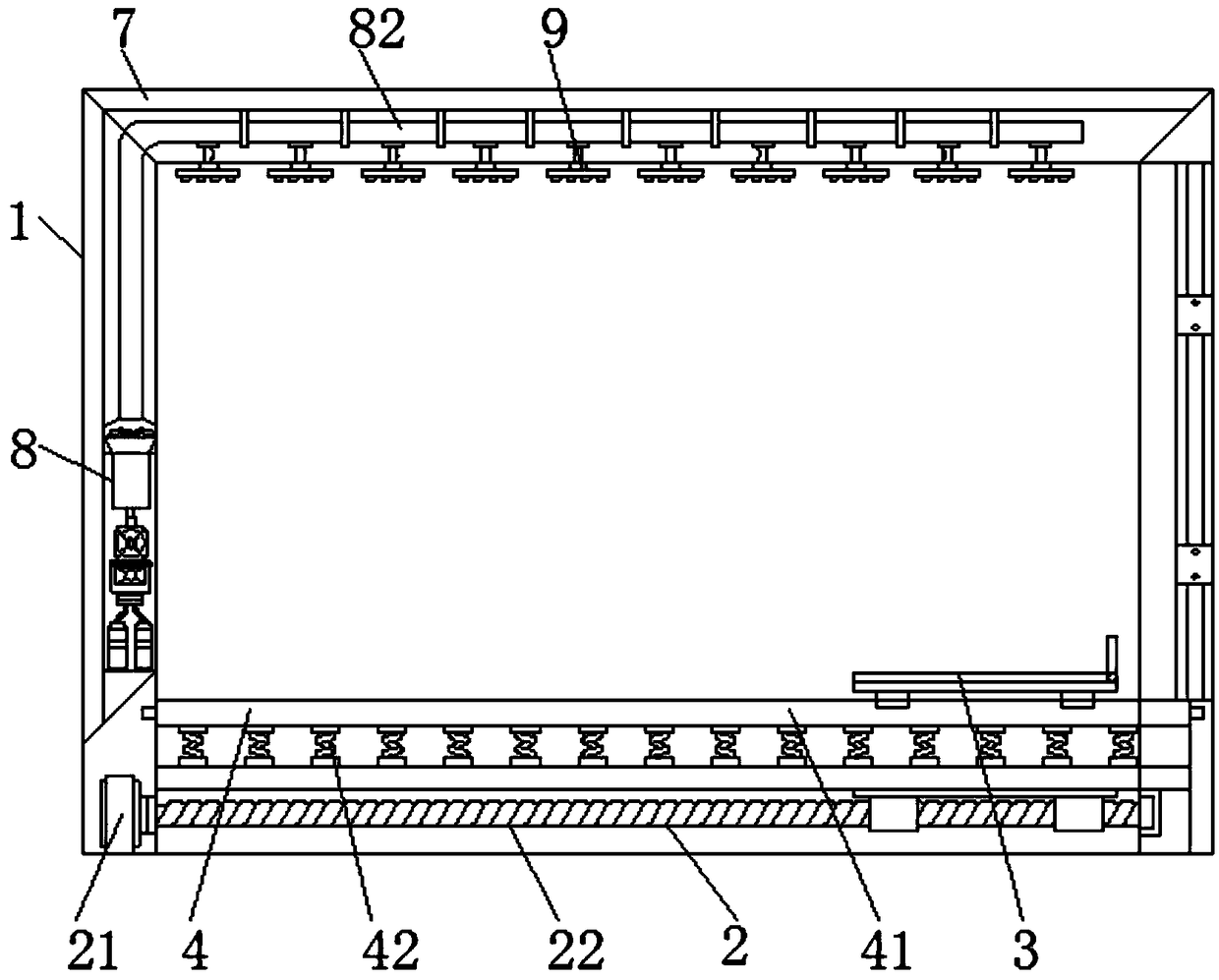

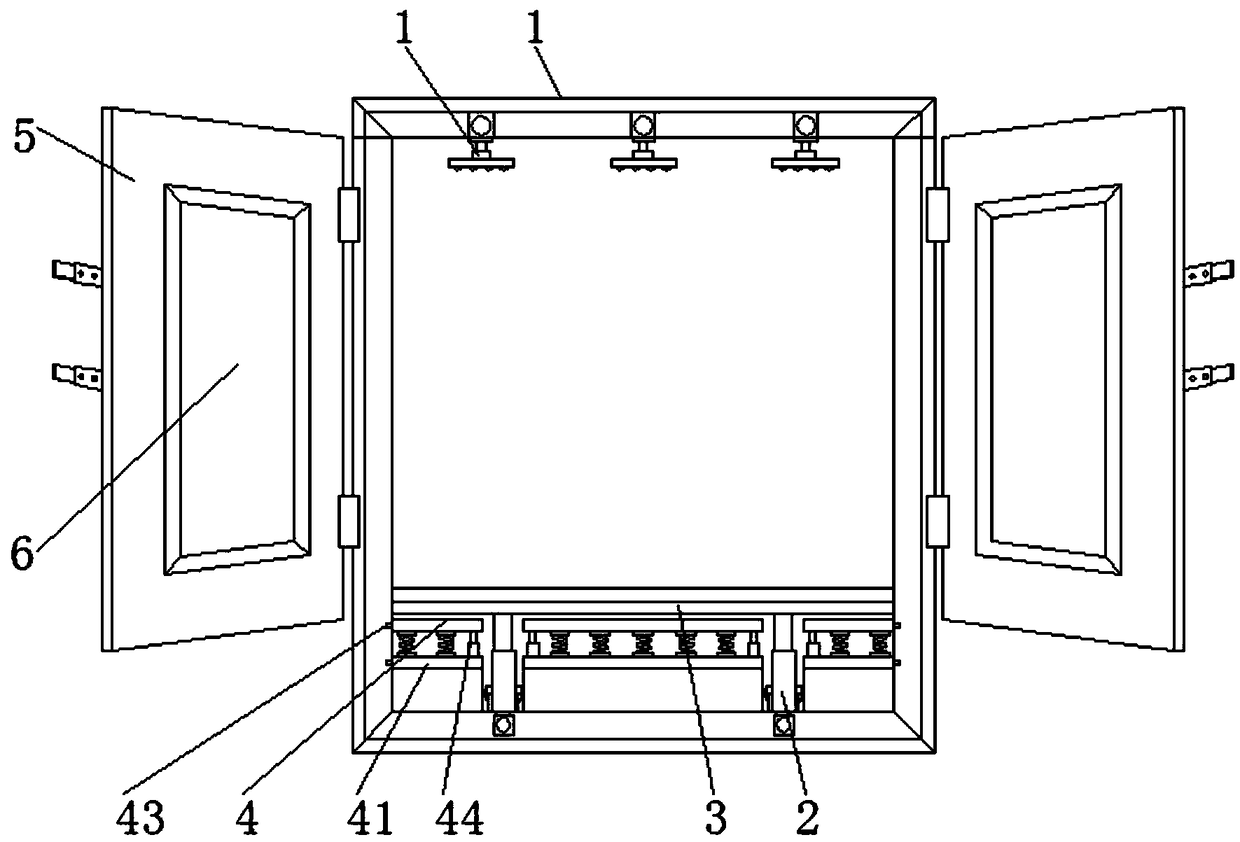

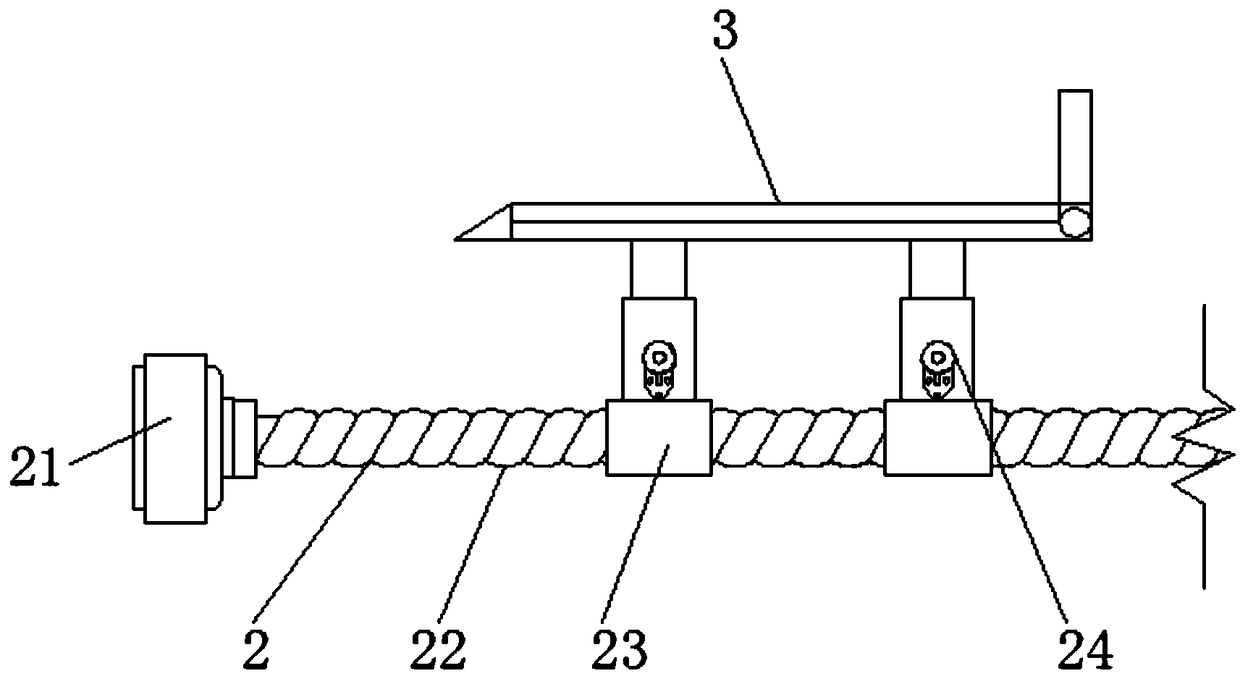

Biological antibody culture device and culture method

ActiveCN111304082ASolve labor-intensive technical problemsQuick addBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyNutrition

The invention discloses a biological antibody culture device and culture method. The culture device includes a culture box body; a bearing groove is installed on one side of the culture box body; a material storage cabin is fixedly installed inside a nutrition box body; multiple liquid discharging pipes are fixedly installed at the bottom of the material storage cabin; one side of the bearing groove is provided with a belt conveyor for conveying bearing plates; the upper part of the belt conveyor is provided with a supporting rack; two moving and carrying mechanisms are movably installed on the supporting rack; the inner side of the culture box body is horizontally provided with a supporting plate; multiple supporting seat sets are installed on vertical plates in a vertical direction; andthe top of the supporting seats are in hinged joint with overturning plates. The culture device enhances the production efficiency of biological antibodies, so that the mass production of the biological antibodies can be realized; manual carrying is not needed by adopting an automatic carrying technology during culturing, so that labor intensity can be reduced; and manual contact is not needed when nutrient solutions are added, so that safe and clean culture environments can be guaranteed.

Owner:通用生物(安徽)股份有限公司

Automatic paint drying room for production line

InactiveCN107344164ASave electricity resourcesEasy to usePretreated surfacesCoatingsThermometerEngineering

The invention discloses a paint drying room for an automatic assembly line, which comprises a sun-proof top board, a wall body, an automatic rolling door and a radiator. A drying electric board is arranged under the storage battery, a thermometer is arranged under the drying electric board, an air purifier is arranged on one side of the thermometer, and an anti-seepage water layer is arranged under the air purifier. A slide belt is provided under the anti-seepage layer, an assembly line inlet is provided on one side of the slide belt, and the wall body is fixedly connected with the radiator. A paint drying room for an automatic assembly line according to the present invention is equipped with a solar panel, an air purifier and a sliding belt, which can generate electricity through solar energy, save resources, purify the air, and save manpower without manual handling. Different working conditions bring better prospects for use.

Owner:浙江安吉江森自控机电科技有限公司

Shoe sole forming device

The invention discloses a shoe sole forming device which comprises a heating device, a pressing device, a cooling device and a pushing device; the heating device is used for heating a shoe sole; the pressing device is located above the heating device and used for pressing the shoe sole when the heating device heats the shoe sole; the cooling device is located on one side of the heating device andused for cooling the shoe sole; the pushing device is located on the other side of the heating device and used for pushing the shoe sole to the cooling device. Full-automatic process production from heating shaping to cooling shaping is achieved, the automation degree is high, the labor cost is saved, and the shoe sole shaping effect is good.

Owner:鹤山市新易高鞋业有限公司

Copper wire automatic production line

The invention relates to a copper wire automatic production line in order to overcome the defects of large labor intensity of extrusion procedure, inconvenience for carrying, low automatic degree of equipment in the production technology of brass wire blanks. The copper wire automatic production line comprises an extrusion device, a material coiling device, a cooling device and a material receiving device, wherein the extrusion device and the material coiling device are arranged in order and connected with an arc-shaped double-flow-guide mechanism; the double-flow-guide mechanism is directly connected with the material coiling device; and a material moving mechanism is connected between the material coiling device and the cooling device. The material coiling device is located in the post-order work direction of the extrusion device, the temperature is increased after the copper wire blank passes through the extrusion device and the copper wire blank is directly wound on the material coiling device through the double-flow-guide mechanism; the temperature is high during winding, therefore the blending resistance of copper wires is small and the wire coiling difficulty is lowered; and besides, the needed power is small, the power waste of the material coiling device can be reduced, and the arc formed by bending at a high temperature is more complete than that formed by bending after cooling.

Owner:NINGBO CHANGZHEN COPPER CO LTD

A biological antibody culture device and culture method

ActiveCN111304082BIncrease the number ofIncrease productivityBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyNutrition

Owner:通用生物(安徽)股份有限公司

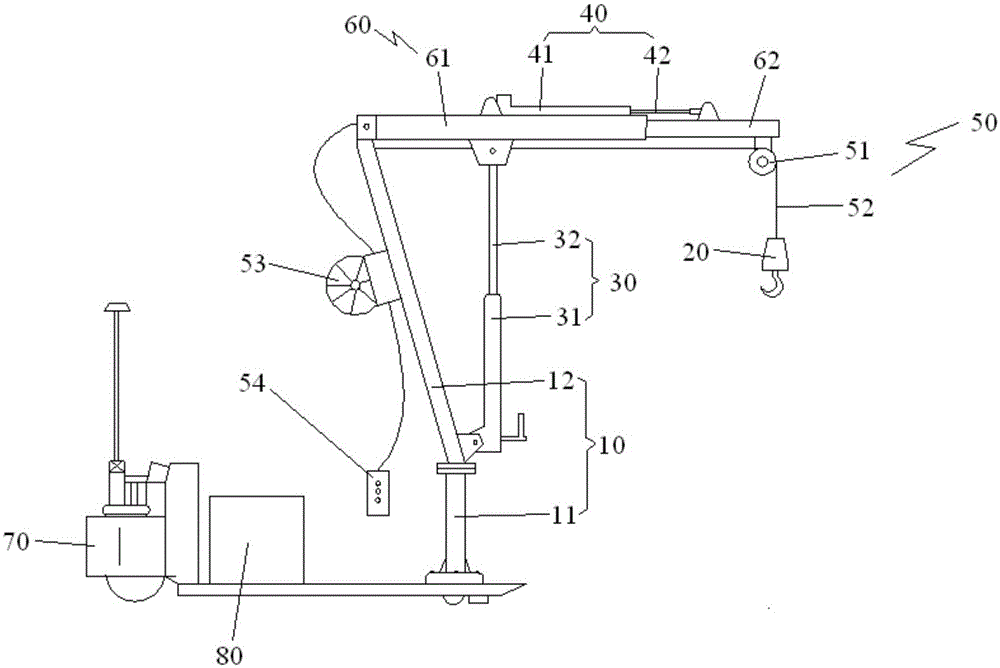

A fresh-keeping hollow ice cube handling device

ActiveCN109231083BMove quicklyImprove handling efficiencyLifting devicesStructural engineeringMechanical engineering

Owner:HUBEI SHUANGGANG AGRI SCI & TECH TRADE CO LTD

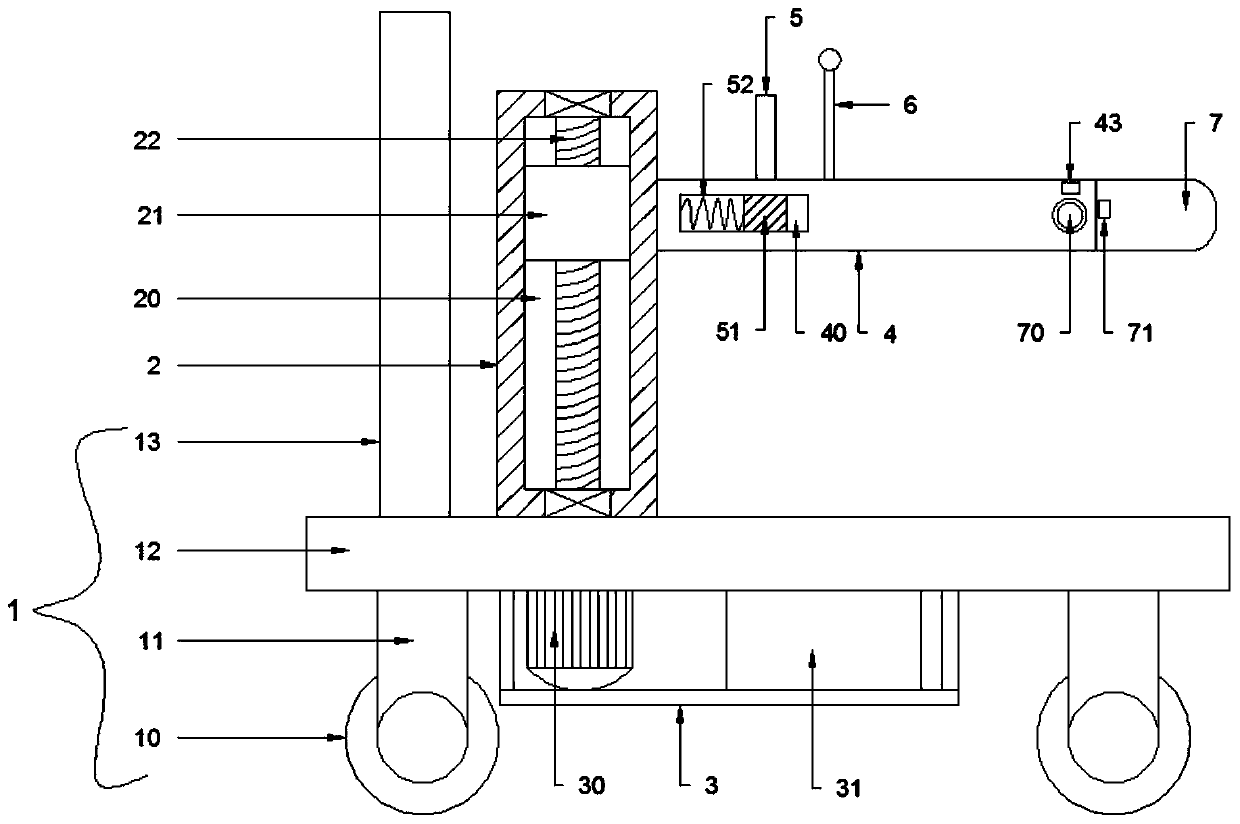

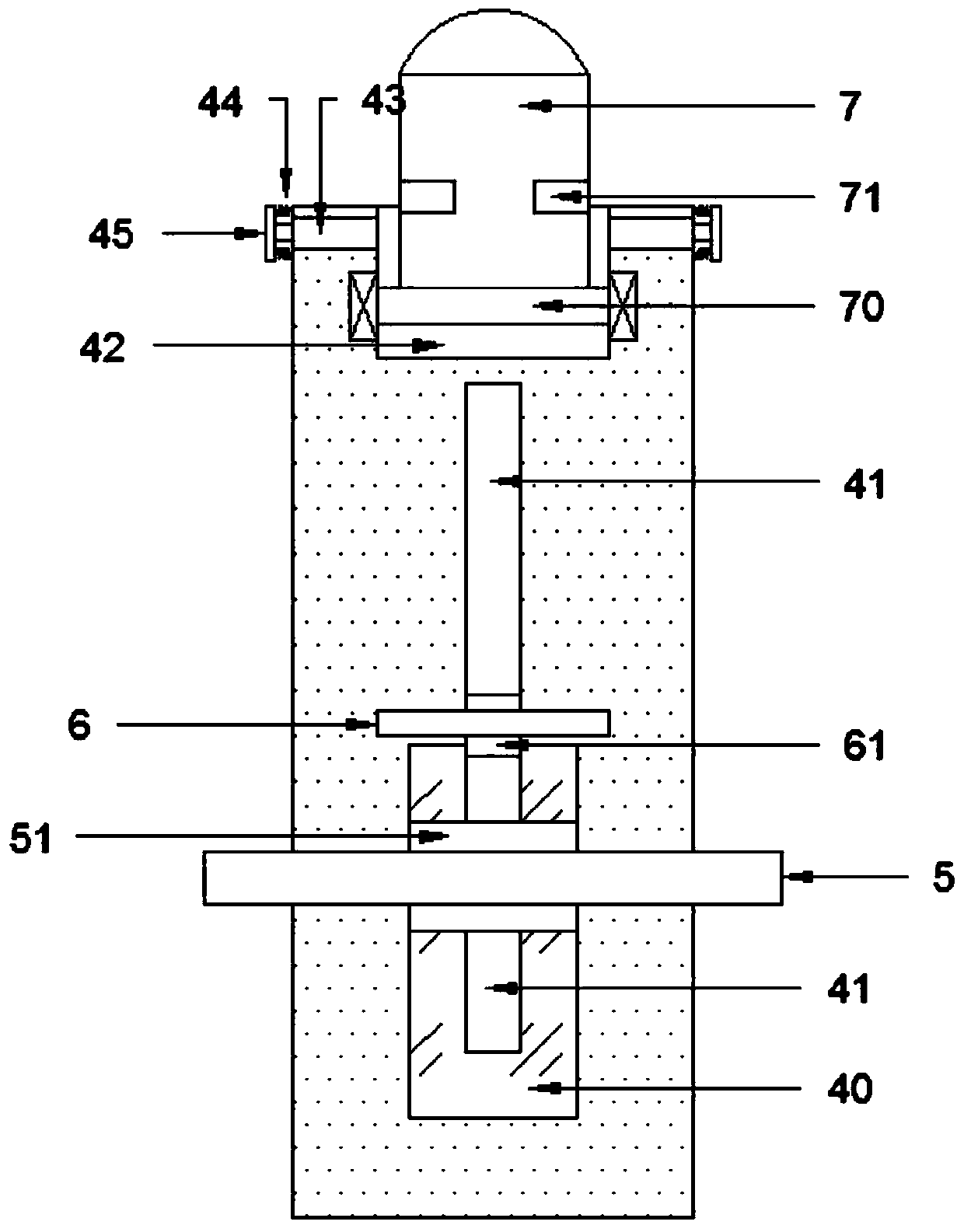

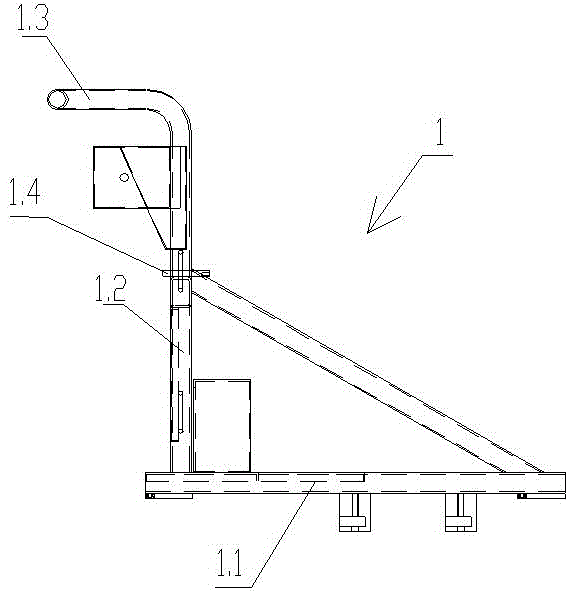

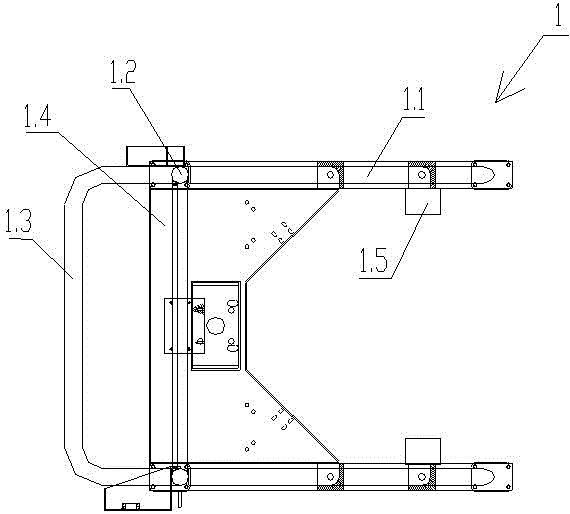

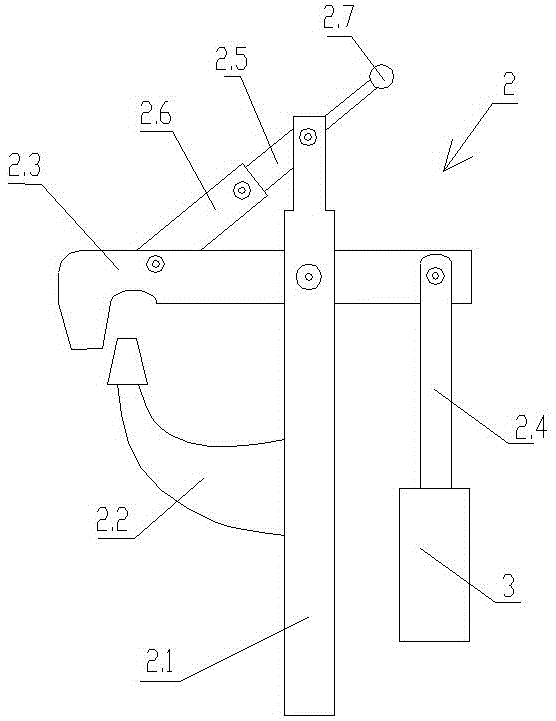

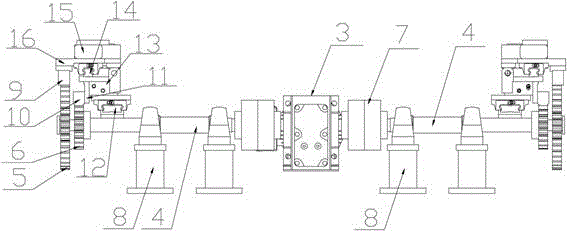

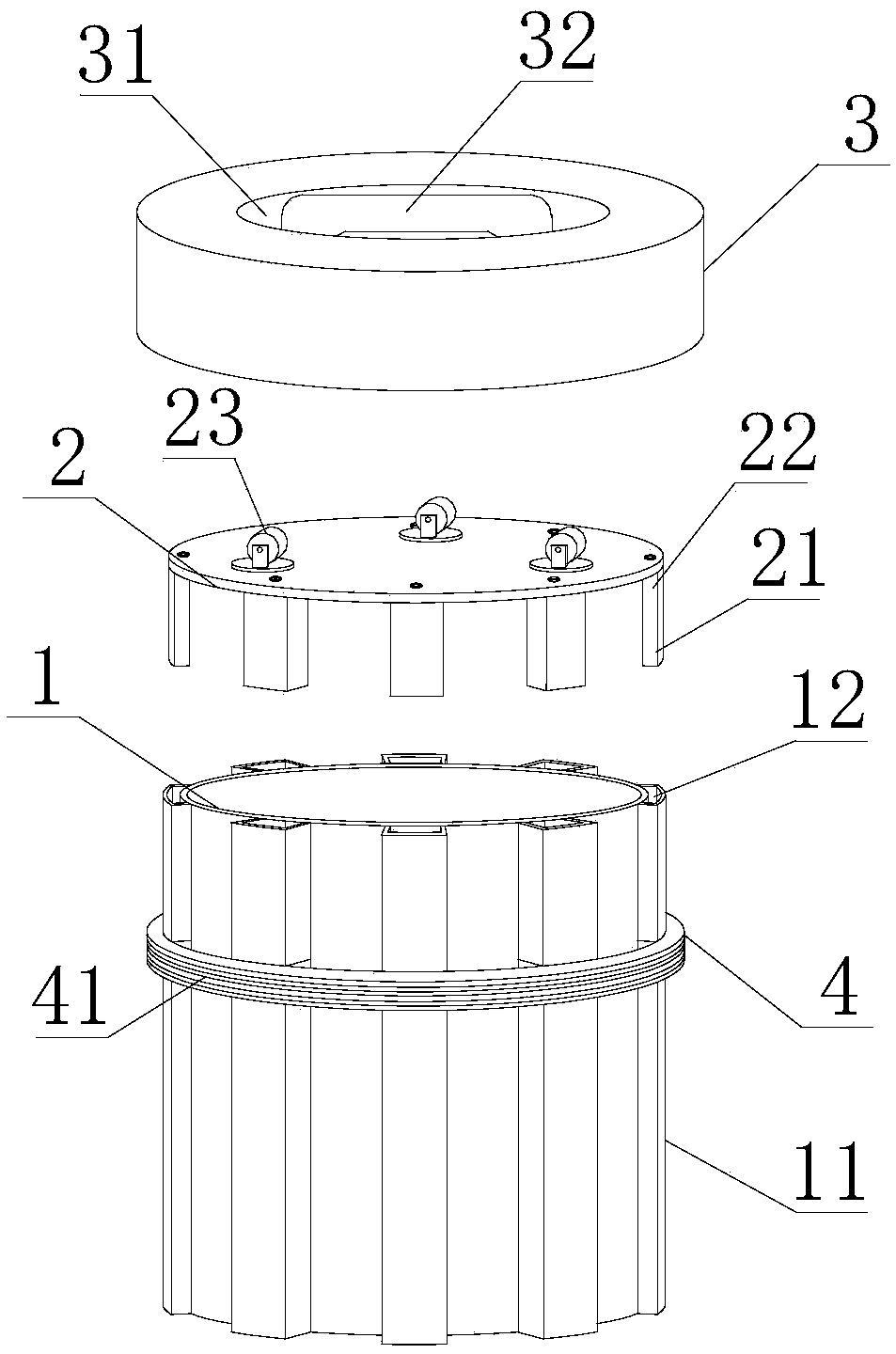

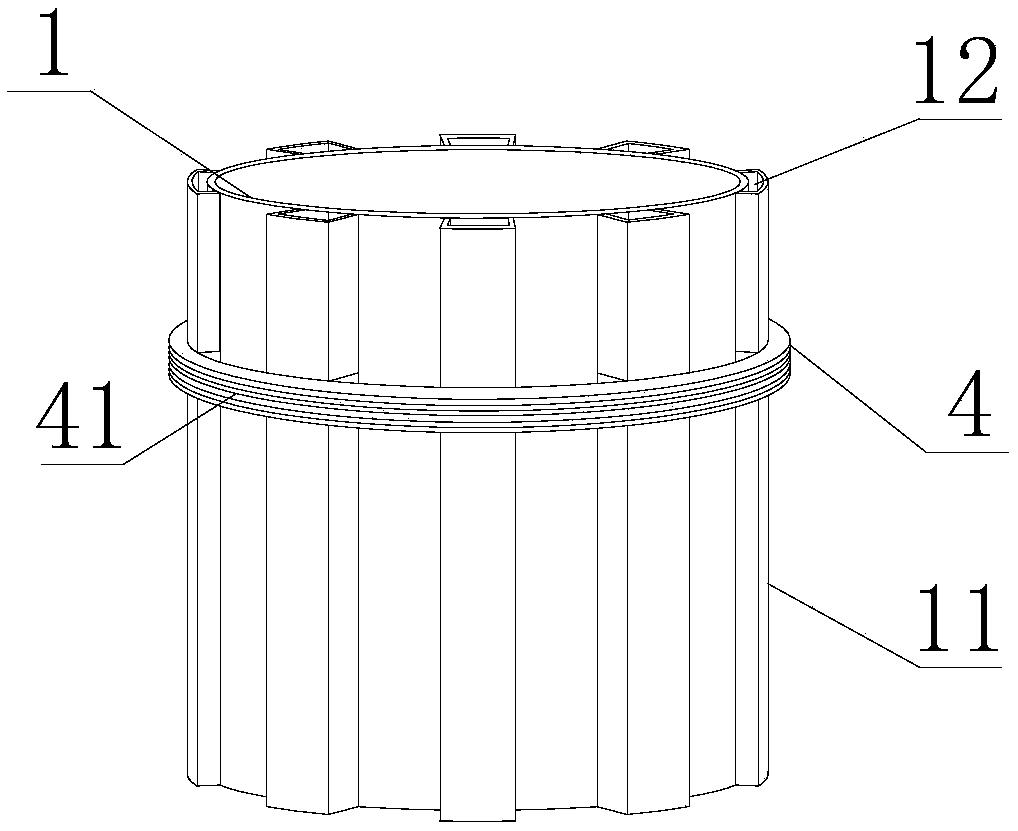

Movable urea injection machine and moving method thereof

The invention provides a movable urea injection machine and a moving method thereof. The movable urea injection machine comprises a frame (1), a clamping mechanism (2) and a power mechanism (3). The frame (1) comprises a base (1.1). The bottom of the base (1.1) is provided with rolling wheels, supporting pieces (1.5) are hinged to the two sides of a U-shaped opening of the base (1.1), and torsional springs are arranged between the supporting pieces (1.5) and the base (1.1). The clamping mechanism (2) comprises a supporting column (2.1) vertically arranged on the frame (1). A clamping piece (2.2) is connected to the supporting column (2.1). The supporting column (2.1) is hinged to the middle of a swing rod (2.3). The bent end of the swing rod (2.3) is provided with a protruding block close to the top of the clamping piece (2.2). A connecting rod (2.4) is hinged to the other end of the swing rod (2.3) and connected with a power mechanism (3). By the adoption of the movable urea injection machine and the moving method thereof, use is convenient, and cost is low.

Owner:JIANGYIN FUREN HIGH TECH

Built-in pneumatic double-helix flow-guiding automatic fastener rinsing tank

InactiveCN107282520AGuaranteed Continuity and SecurityFast dryingCleaning using liquidsHeating arrangementFastenerEngineering

The invention provides a pneumatic flow-guiding automatic fastener acid-pickling cleaning tank. The pneumatic flow-guiding automatic fastener acid-pickling cleaning tank comprises a shell and a conveying belt, wherein the two ends of the shell are opened, and the conveying belt is arranged inside the shell. The shell is provided with a cleaning tank body and a drying tank. A rolling rack is arranged in the cleaning tank body. A water inlet is formed in the top of the cleaning tank body, and a water outlet is formed in the bottom of the cleaning tank body. An air blowing device is arranged in the drying tank. An opening is formed between the cleaning tank body and the drying tank, wherein the opening allows the conveying belt to pass through. The conveying belt is horizontally arranged, passes through the shell, penetrates openings in the two ends of the shell an extends out of the shell. The pneumatic flow-guiding automatic fastener acid-pickling cleaning tank is diversified in function; cleaning and drying can be conducted simultaneously; the cleaning effect is good; a great amount of cleaning work can be completed each time; the cleaning tank can operate continuously; and cleaning efficiency is greatly improved.

Owner:NINGBO CITY YINZHOU FENGMING IND PROD DESIGN

Quick drying device for spraying

InactiveCN104646255AUniform drying temperatureGood qualityPretreated surfacesCoatingsEngineeringEnergy consumption

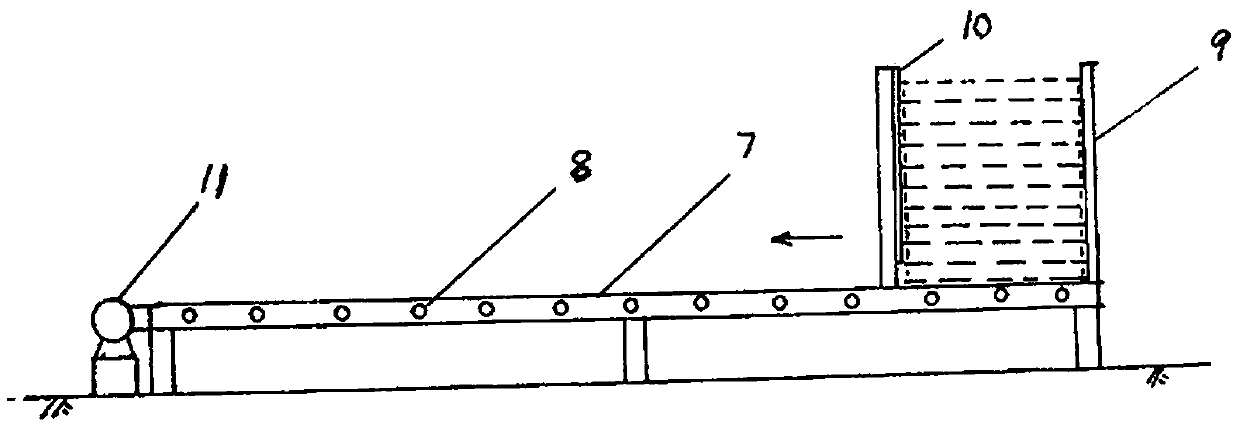

The invention discloses a quick drying device for spraying. The quick drying device comprises an elongated tunnel, a heat exchanger, a blower and a heating device. A guide rail is fixed on the top wall of the tunnel, a product conveying frame capable of sliding along the guide rail is arranged on the guide rail, a plurality of hot air inlets are formed in the lower end of the side wall of the tunnel, a plurality of cold air outlets are formed in the upper end of the side wall of the tunnel, a heating medium outlet of the heating device is connected with a heating inlet of the heat exchanger through a pipeline, a heating outlet of the heat exchanger is connected with a heating medium return port of the heating device through a pipeline, the blower is connected with an air inlet of the heat exchanger, a hot air outlet of the heat exchanger is respectively connected with the hot air inlets in the side wall of the tunnel through pipelines, and the cold air outlets in the side wall of the tunnel are connected with an air inlet of the blower through a pipeline. Drying temperature is uniform, products are not easily cracked, the tunnel is long and large in volume and contains more products, and the quick drying device is low in cost, high in efficiency, low in energy consumption and high in productivity.

Owner:HEBEI ORIENT SUNDAR WINDOW

Inorganic fireproof expanded perlite insulation board automatic palletizing device

InactiveCN105501989BAchieve alignmentRapid succession crawlingStacking articlesDe-stacking articlesStack machineMaterials science

Owner:南通景禾佳信息科技有限公司

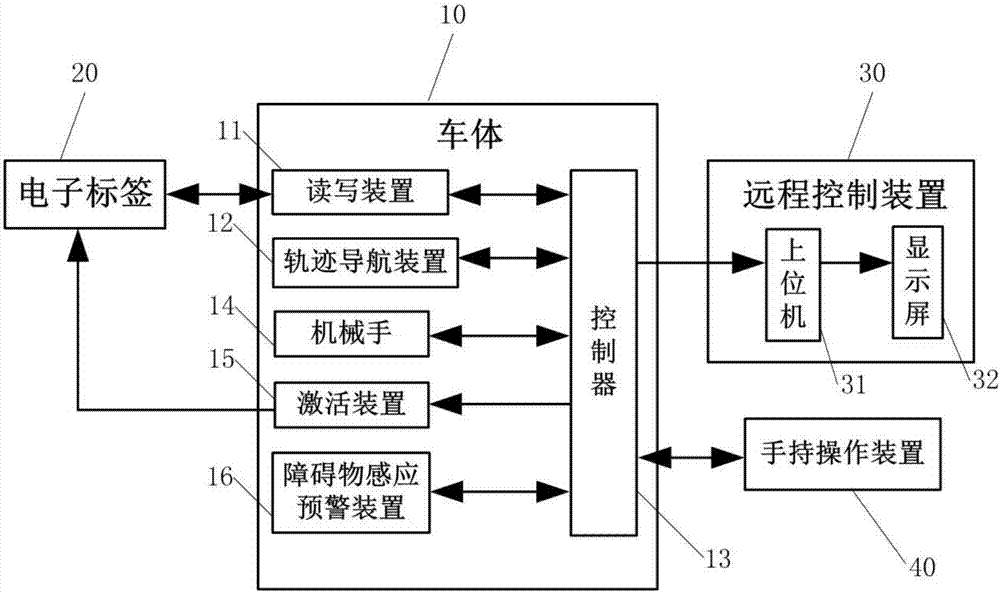

Intelligent carrier control system based on electronic tag

InactiveCN107357289ANo manual handlingImprove automationCo-operative working arrangementsPosition/course control in two dimensionsRemote controlControl system

The invention discloses an intelligent carrier control system based on electronic tag. The system herein includes: a vehicle body; an electronic tag which is disposed on a to-be-identified object; a read-write apparatus which is arranged on the vehicle body and reads the information of the to-be-identified object that is written in the electronic tag corresponding to the to-be-identified object; a track navigation apparatus which is disposed on the vehicle body and is provided with a magnetic stripe identifying sensor for performing navigation; a controller which is disposed on the vehicle body and is in separate and communicative connection to the read-write apparatus and the track navigation apparatus; and a remote control apparatus which includes an upper computer and a display which is connected to the upper computer, wherein the upper computer is in communicative connection to the controller. The vehicle body also includes a mechanical arm which is for carrying and is in communicative connection to the controller. According to the invention, the carrier and cargo realize intelligent identification through an electronic tag, realize carrying through the mechanical arm, so that the system obviates manual carrying and has higher automation and intelligence.

Owner:SUZHOU MEITIAN NETWORK TECH CO LTD

Copper wire automatic production line

The invention relates to a copper wire automatic production line in order to overcome the defects of large labor intensity of extrusion procedure, inconvenience for carrying, low automatic degree of equipment in the production technology of brass wire blanks. The copper wire automatic production line comprises an extrusion device, a material coiling device, a cooling device and a material receiving device, wherein the extrusion device and the material coiling device are arranged in order and connected with an arc-shaped double-flow-guide mechanism; the double-flow-guide mechanism is directly connected with the material coiling device; and a material moving mechanism is connected between the material coiling device and the cooling device. The material coiling device is located in the post-order work direction of the extrusion device, the temperature is increased after the copper wire blank passes through the extrusion device and the copper wire blank is directly wound on the material coiling device through the double-flow-guide mechanism; the temperature is high during winding, therefore the blending resistance of copper wires is small and the wire coiling difficulty is lowered; and besides, the needed power is small, the power waste of the material coiling device can be reduced, and the arc formed by bending at a high temperature is more complete than that formed by bending after cooling.

Owner:NINGBO CHANGZHEN COPPER CO LTD

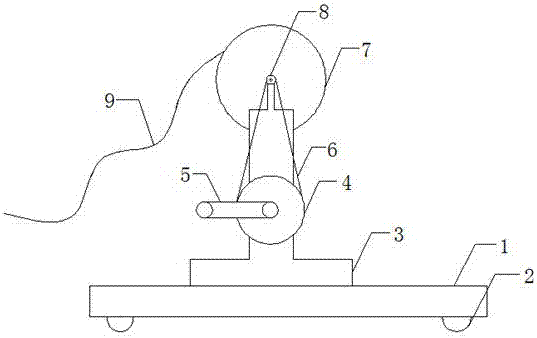

Construction method for quickly recycling patch cables

InactiveCN106865341AFast winding speedThere will be no messy and difficult to sort out problemsFilament handlingGear wheelEngineering

The invention discloses a construction method for quickly recovering temporary cables, which comprises a small trolley, a roller bracket and a roller, rollers are installed on the bottom of the trolley, a roller bracket is installed on the top of the trolley, and the roller A roller and a pinion are installed on the top of the bracket, a large gear is installed on one side of the lower end of the roller bracket, a handle is installed on the large gear, the small gear is fixedly connected to one end of the roller, and the small gear is connected to the large gear through a chain. The transmission is connected, and the cable is wound on the roller. The roller bracket is fixed and installed on the top of the trolley by bolts, and is connected by bolts to facilitate disassembly and replacement of the roller bracket. The device rewinds the cable through the roller, which can increase the rewinding speed of the cable, which is convenient and quick, and does not cause the cable to be easily messed up and difficult to sort out when rewinding completely by manpower; the roller It is installed on a small trolley through the roller bracket, and the weight and movement of the reeled cable and roller are carried by the trolley, without manual handling, saving time and effort.

Owner:SHIJIAZHUANG HUAYOU ELECTRONICS CO LTD

Installation device for testing motor

PendingCN106556798ASimple and efficient operationSave operating timeDynamo-electric machine testingSoftware engineeringElectric machine

Owner:BEIJING ELECTRIC VEHICLE

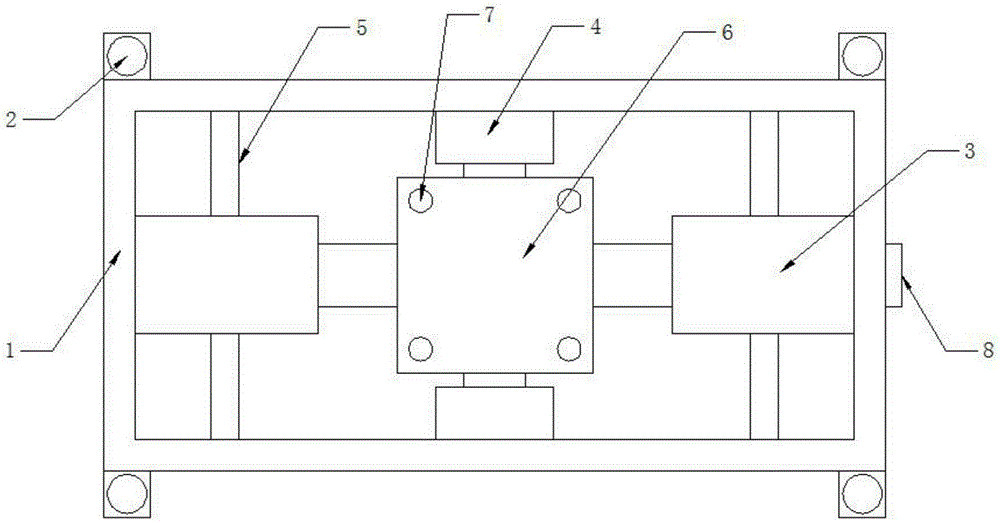

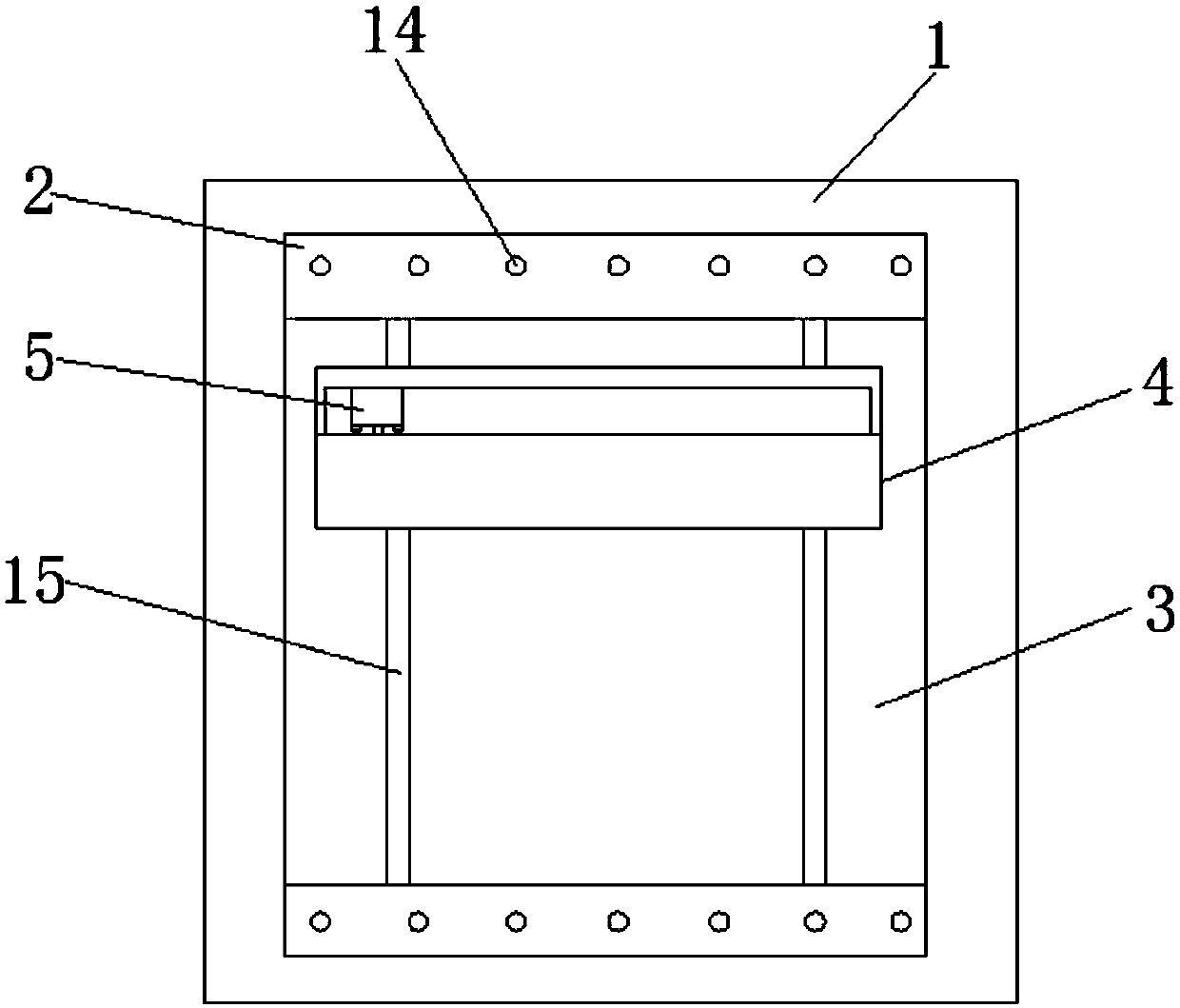

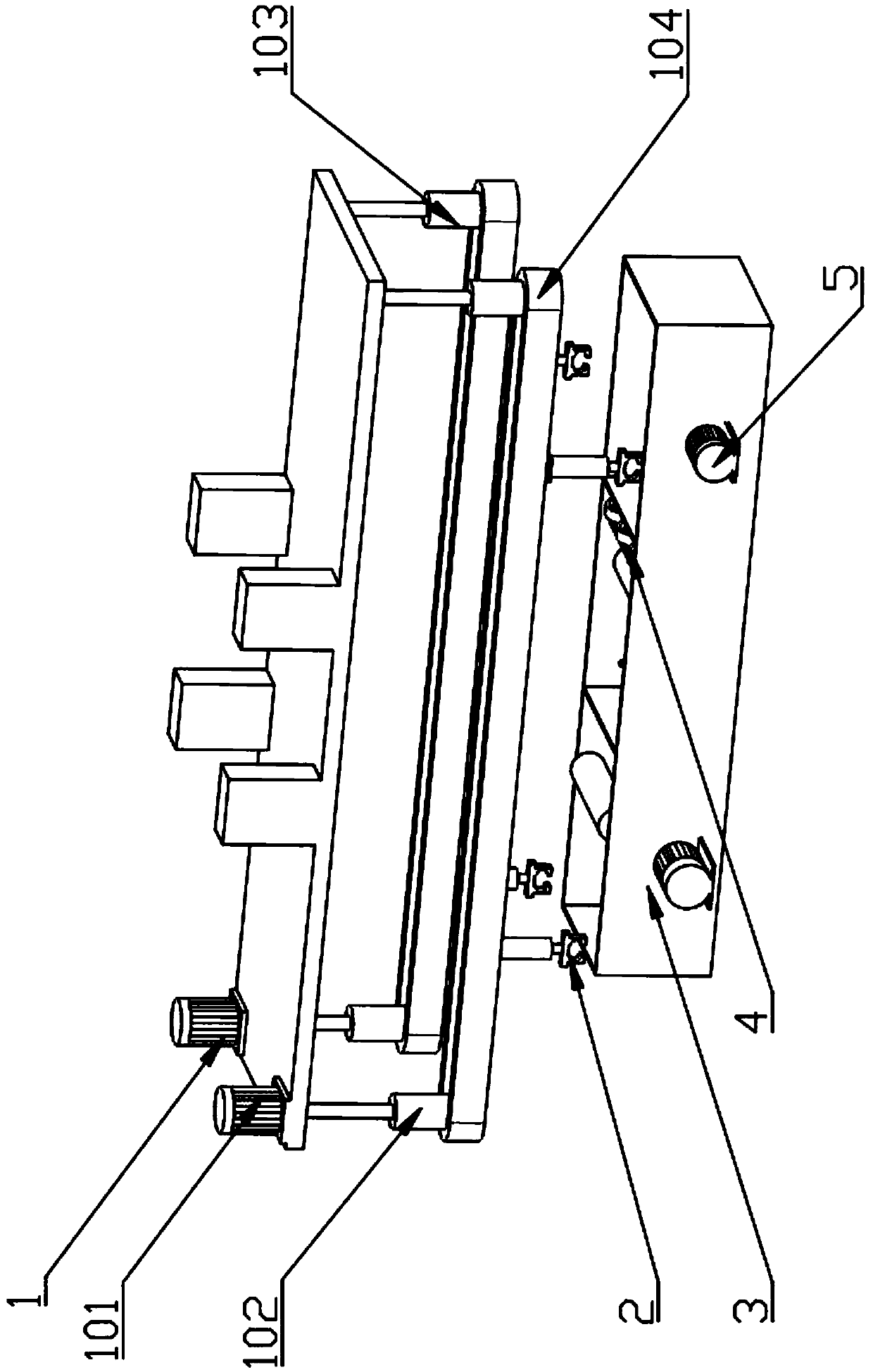

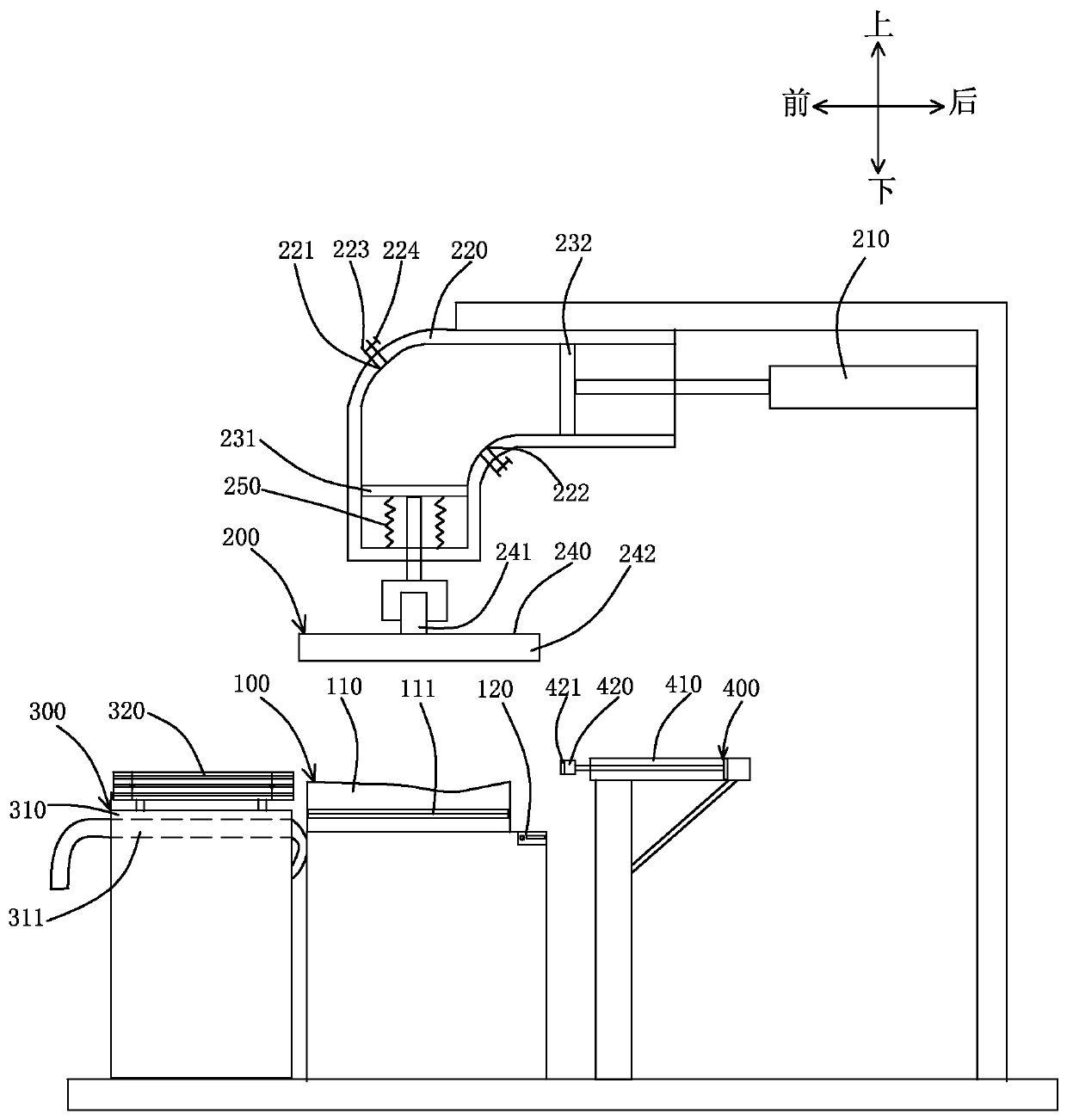

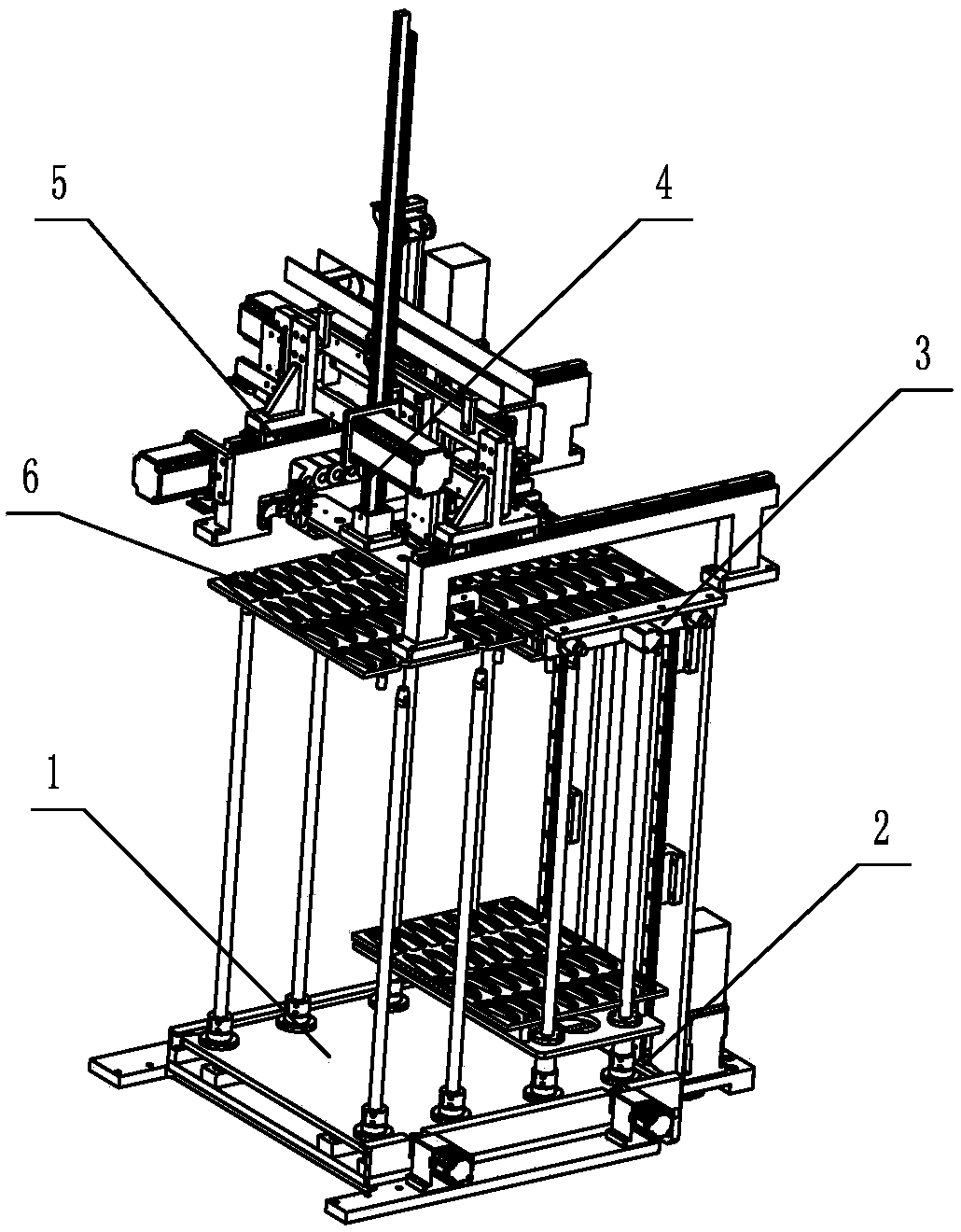

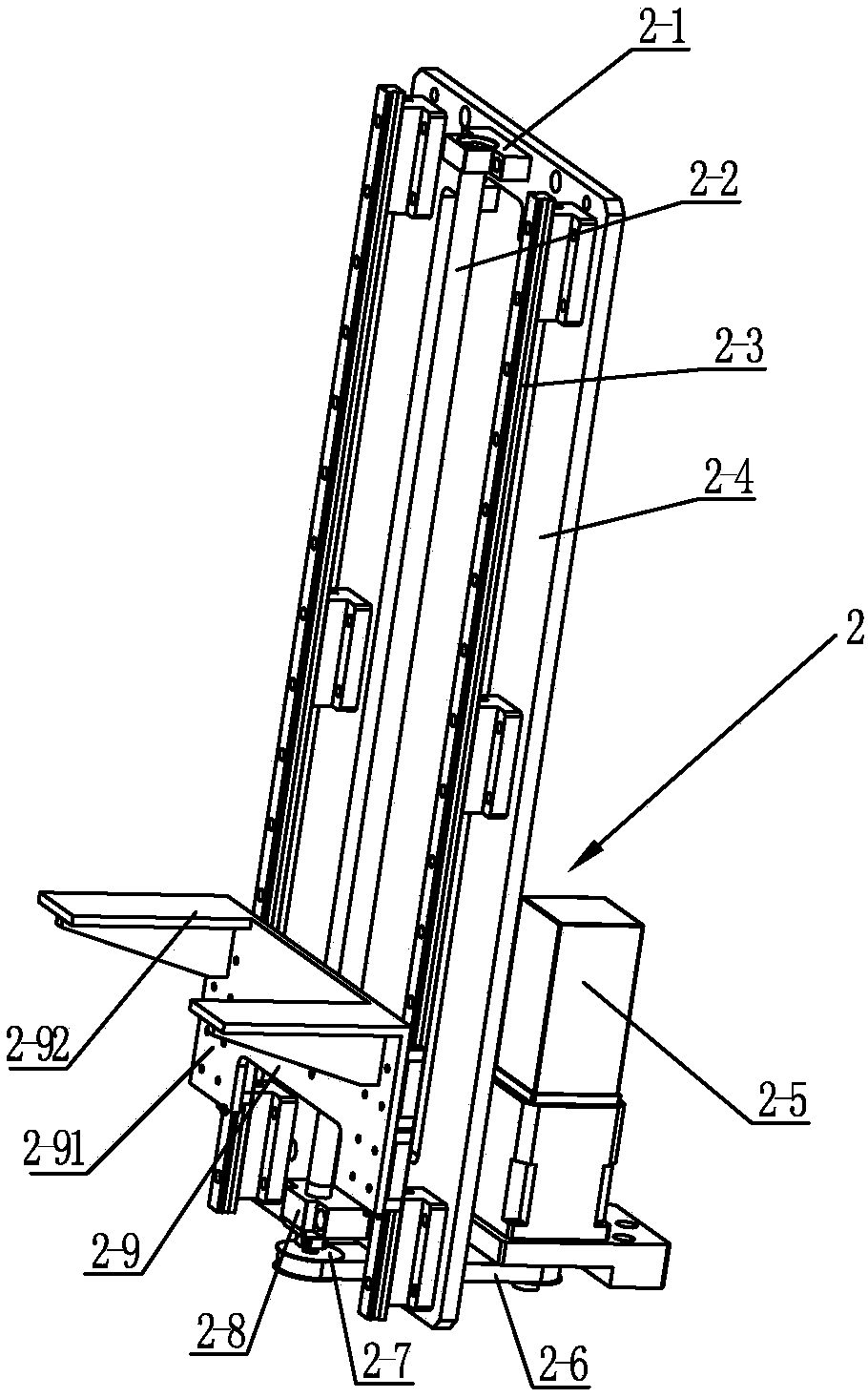

Feeding device for automated production lines

The invention relates to a feeding device for an automated production line. A material disc containing mechanism comprises a limiting seat and a material disc support assembled on the limiting seat in an inserted manner. A first motor of a material disc elevating mechanism is mounted on the lower rear portion of a vertical plate. The first motor is connected with a ball screw through a synchronous belt. A screw nut on an ascending plate is connected to the ball screw in a rotary manner. Gripping seats of a material disc retaining mechanism are located on the upper front portion of the vertical plate. All retaining air cylinders are mounted on the gripping seats. The movable end of each retaining air cylinder is connected with a corresponding clamping seat. An elevating guide rail of a material disc replacing mechanism and a second motor are mounted on a movable gantry of a three-shaft mechanical arm. The second motor is engaged with a rack mounted on the elevating guide rail through a gear. The lower portion of the rack is connected with an air cylinder seat. Two exchange air cylinders are mounted on the air cylinder seat. The movable side of each exchange air cylinder is connected with a corresponding disc clamp. The feeding device for the automated production line is reasonable in structure; space can be utilized completely; feeding can be conducted automatically, and empty material discs can be recycled; and production efficiency can be remarkably improved.

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST CO LTD

A conveying mechanism for a car door

ActiveCN103482319BImprove delivery efficiencyKeep shapeConveyor partsMechanical conveyorsDrive shaftCar manufacturing

The invention relates to a conveying mechanism of an automobile door and belongs to the technical field of automobile manufacturing. The conveying mechanism of the automobile door comprises an underframe, a delivering mechanism, a transferring mechanism and guiding mechanisms, wherein the delivering mechanism, the transferring mechanism and the guiding mechanisms are arranged on the underframe, a climbing mechanism is arranged on the bottom of the delivering mechanism, the guiding mechanisms are symmetrically arranged on the two sides of the delivering mechanism and are fixed on the underframe, the transfering mechanism comprises a double-layered sliding rail, a motor, transmission shafts, main gears and pinions, the transmission shafts, the main gears and the pinions are arranged on the two ends of the motor respectively, the double-layered sliding rail comprises a lower sliding rail assembly and an upper sliding rail assembly, a first rack is correspondingly arranged above each main gear, a second rack is correspondingly arranged above each pinion, the first racks are meshed with the main gears, the second racks are meshed with the pinions, and the first racks and the second racks are fixedly connected to the upper sliding rail assembly and the lower sliding rail assembly respectively. The conveying mechanism of the automobile door has the advantages that the automation degree is high, the whole conveying process can be achieved stably, safety and reliability are guaranteed, quality of products is guaranteed, labor intensity of workers is relieved, and workpiece conveying efficiency is improved.

Owner:烟台宇信科技有限公司

Novel environment-friendly dustproof agent auxiliary construction device

InactiveCN109178598APlay a sealing roleAchieve fixationRemovable lids/coversSealingEnvironmental resistanceArchitectural engineering

The invention provides a novel environment-friendly dustproof agent auxiliary construction device. The novel environment-friendly dustproof agent auxiliary construction device is provided with an inner cover and an outer cover. The inner cover plays a main sealing role, and is detachably fixed together with a fixing ring through a bolt. A sealing gasket is arranged between the inner cover and a containing barrel, can be repeatedly used, is good in sealing effect, and meets the policy requirements of energy conservation and environmental protection. Due to the design of roller wheels, the position of the containing barrel is convenient to move without manual handling, convenience is brought to construction, and the working efficiency is improved. The novel environment-friendly dustproof agent auxiliary construction device comprises the containing barrel and a barrel cover, wherein a plurality of protection columns are circumferentially arranged on the outer side of the containing barreland protrude from the lateral side of the containing barrel, and the outer sides of the protection columns are arc surfaces. The barrel cover comprises an inner cover, the upper surface of the innercover is provided with bolt holes, and the inner cover is connected with the protection columns through bolts. The roller wheels are arranged on the inner cover.

Owner:天津市四水化工科技有限公司

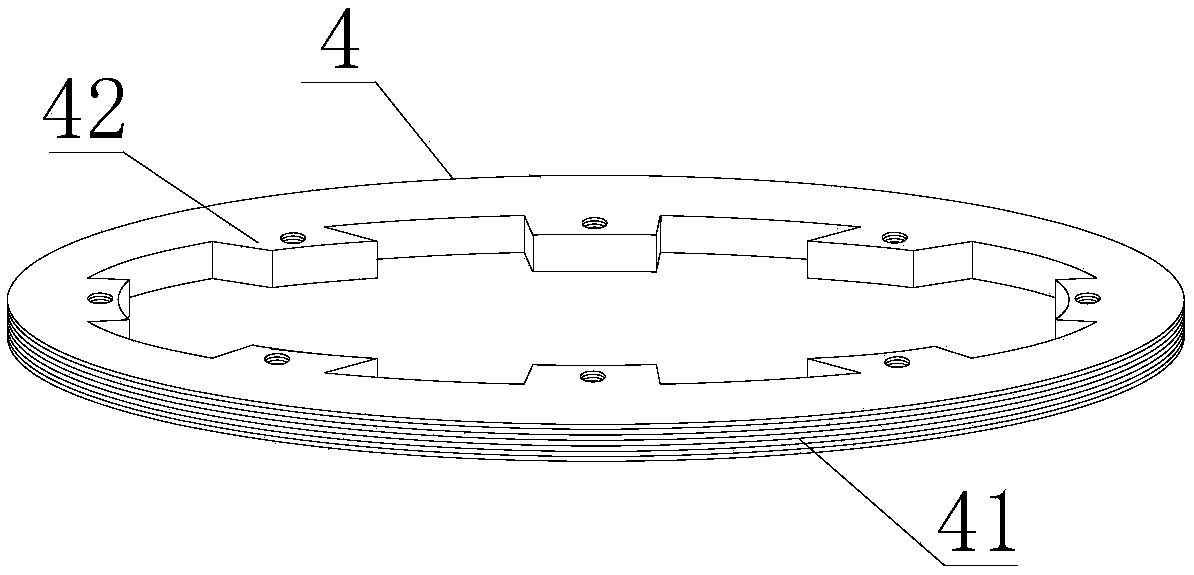

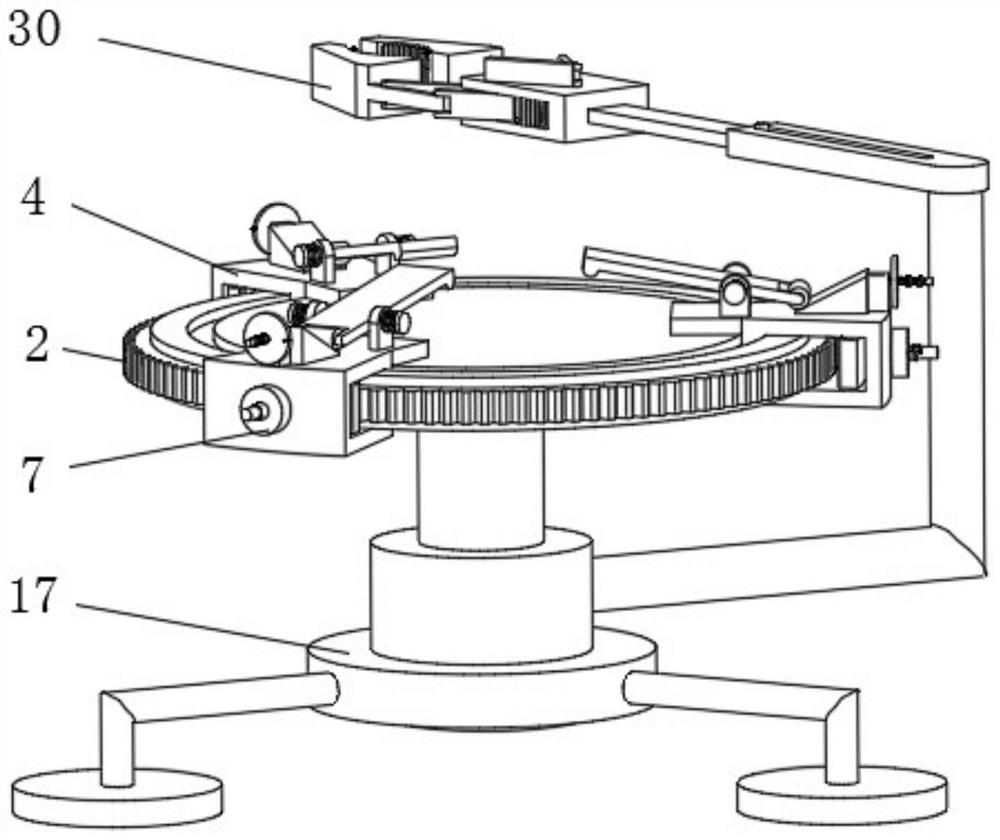

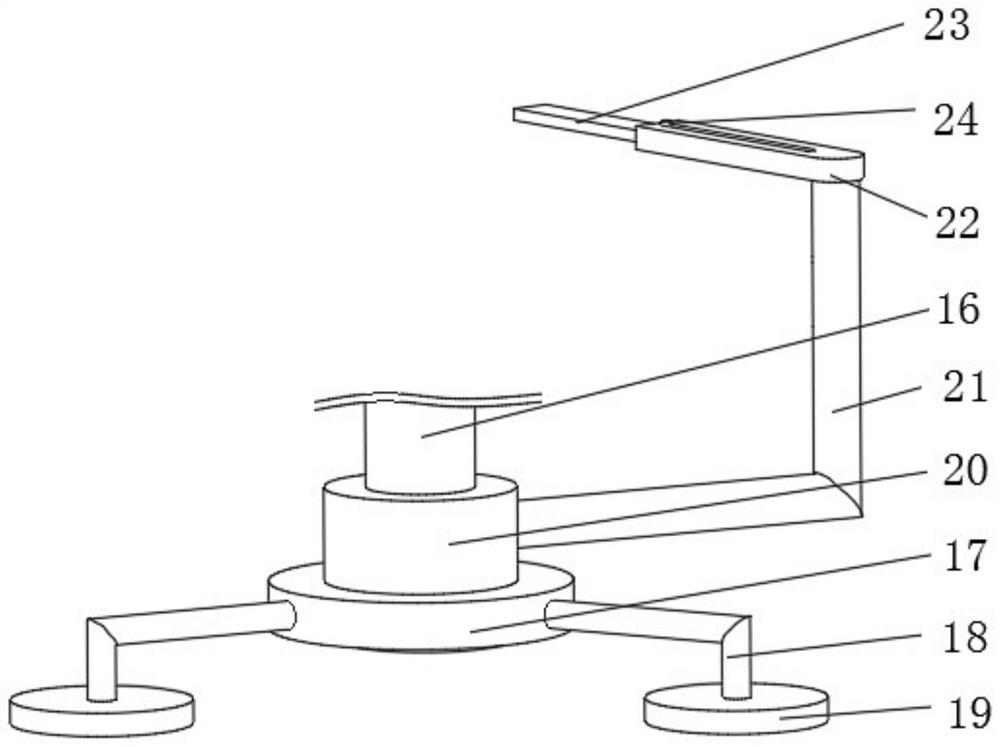

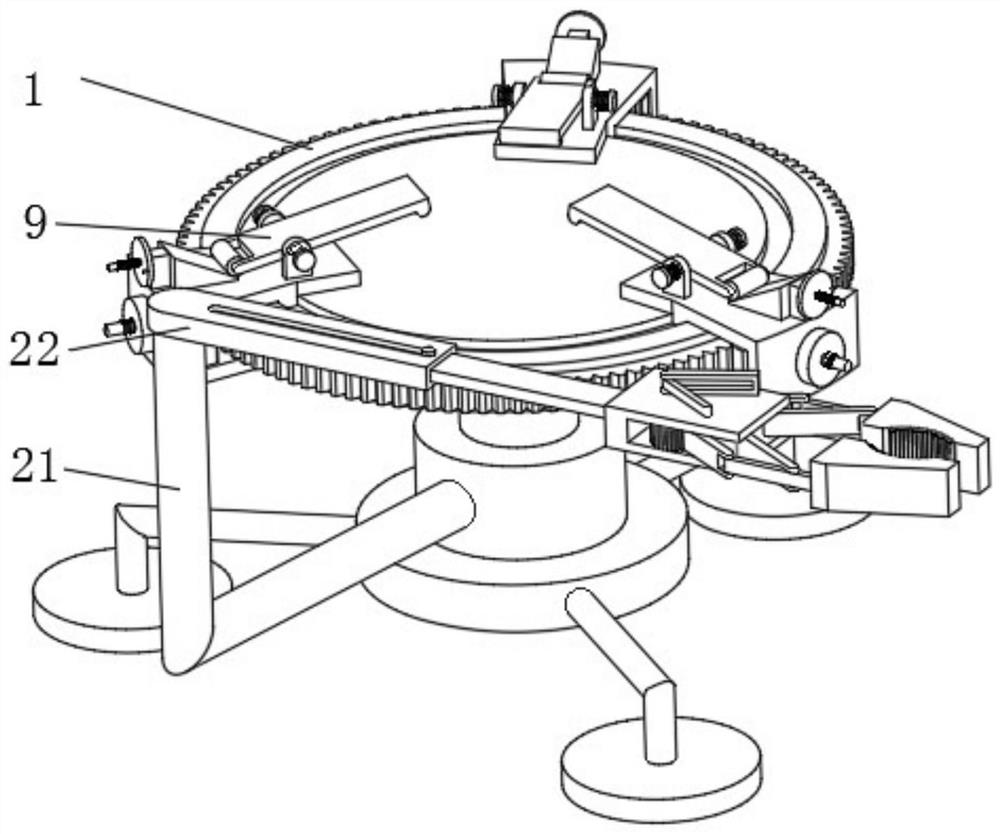

Fastening-position-adjustable stable machining part

PendingCN113084722AEasy to fixEasy to pick and placeGripping headsWork holdersMachine partsEngineering

The invention discloses a fastening-position-adjustable stable machining part, and relates to the field of machining parts. The fastening-position-adjustable stable machining part comprises a workbench, the workbench is fixedly sleeved with a rail gear ring, the top side and the bottom side of the workbench are each annularly provided with a limiting groove, a plurality of limiting sliding blocks are slidably mounted in the two limiting grooves, and the sides, away from each other, of every two limiting sliding blocks are fixedly provided with a same sliding base table movably connected to the workbench in a sleeving mode. According to the fastening-position-adjustable stable machining part, the sliding base tables rotate around the workbench, after the sliding base tables rotate to proper positions, fixing screw barrels are rotated, the fixing screw barrels rotate to drive fixing screw rods to move, the fixing screw rods move to drive arc-shaped teeth to move, the arc-shaped teeth move to be meshed with the rail gear ring, fixing is achieved, therefore, blanks of different sizes and shapes can be fixed by adjusting the the positions of the sliding base tables, the situation that the fixing effect is poor due to the fact that the blanks cannot be fixed or the fixing positions are improper is avoided, and the application range of machining parts is wide.

Owner:杭州溪茉科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com