Quick drying device for spraying

A kind of equipment and quick-drying technology, which is applied to the device, coating, pre-treatment surface, etc. for applying liquid to the surface. Maintain the smoothness of the paint surface and the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

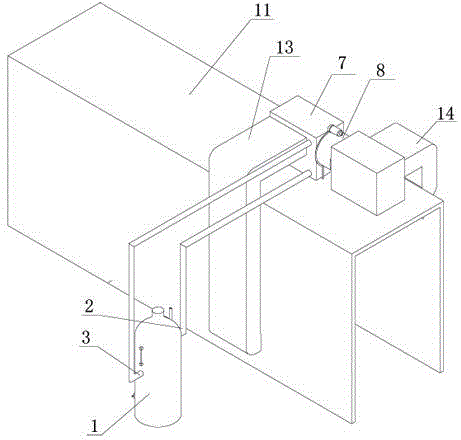

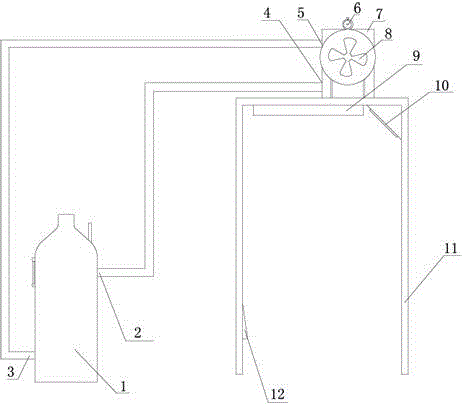

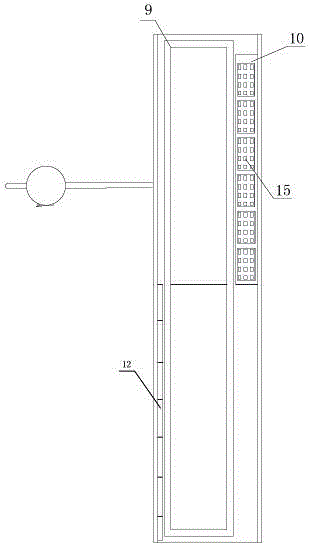

[0013] Such as figure 1 , figure 2 with image 3 As shown, the present embodiment includes a strip-shaped tunnel 11, a heat exchanger 7, a blower 8 and heating equipment: a hot water boiler 1. The top wall of the tunnel 11 is fixed with a guide rail, on which there is a product transfer frame 9 that can slide along the guide rail, and the lower end of the side wall of the tunnel 11 has a plurality of hot air inlets 12, and the upper end has a plurality of cold air outlets 10. The water outlet 2 of the hot water boiler 1 is connected to the heat supply inlet 4 of the heat exchanger 7 through a pipe, and the heat supply outlet 5 of the heat exchanger 7 is connected to the water return port 3 of the hot water boiler 1 through a pipe. Blower 8 is connected to the air inlet of heat exchanger 7, and the hot air outlet of heat exchanger 7 is respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com