Fastening-position-adjustable stable machining part

A mechanical processing and adjustable technology, which is applied in the direction of manipulators, worktables, manufacturing tools, etc., can solve the problems of unfixed shape and size of processed workpieces, narrow application range of machined parts, and non-adjustable positions of fixed components, etc., so as to achieve convenient fixing , good fixing effect and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

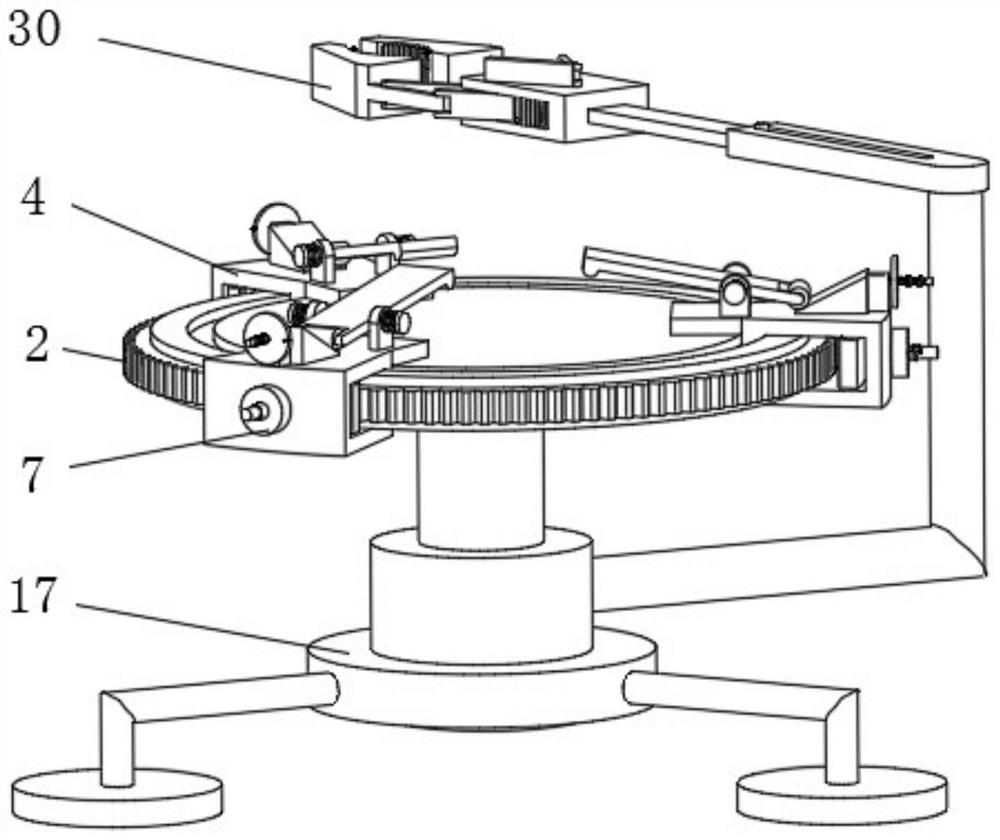

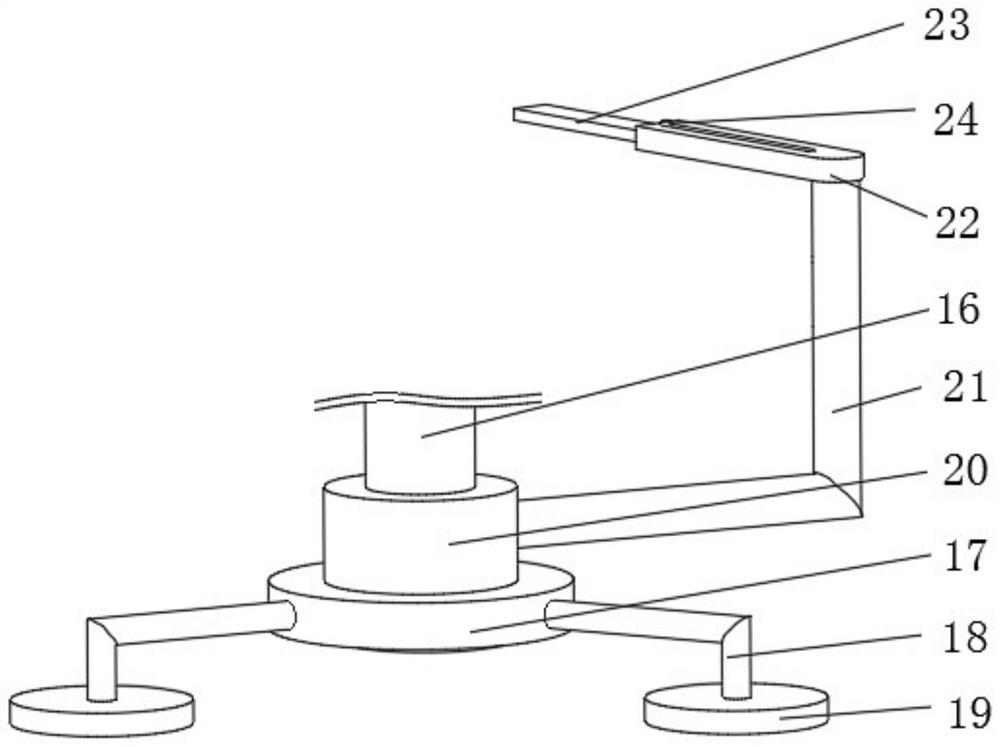

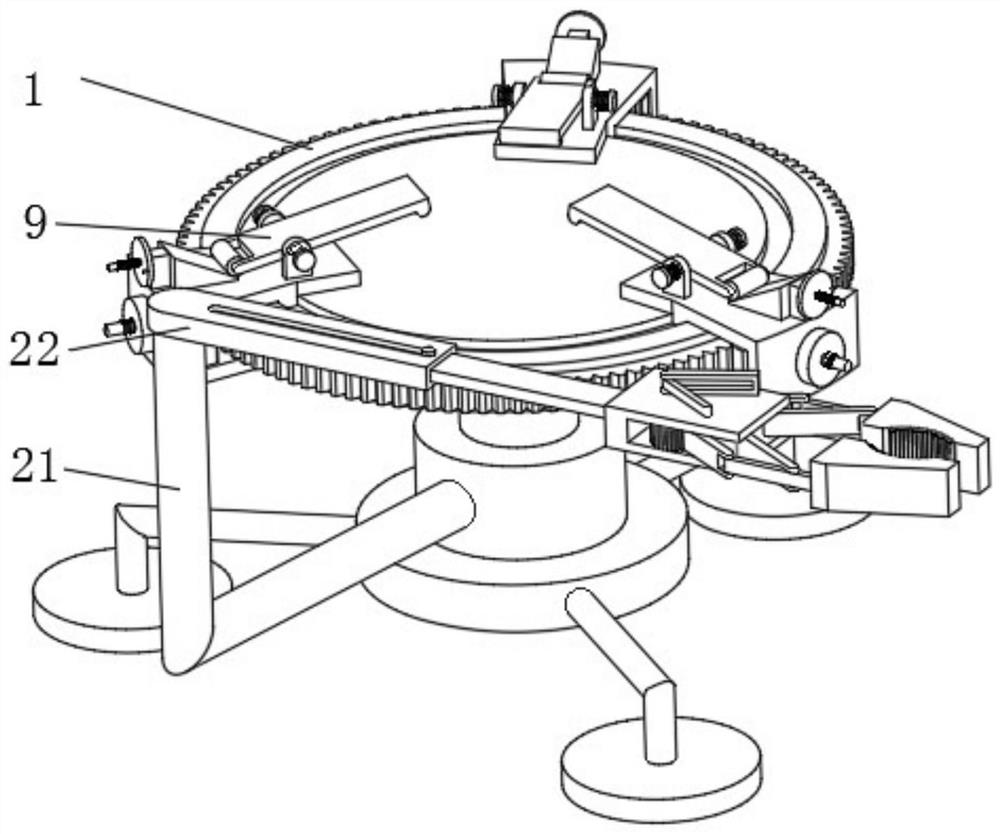

[0042] Example: Reference Figure 1-8 Shown is a stable machined part with adjustable fastening position, including table 1. The workbench 1 can be any base structure in the prior art, such as a metal plate body.

[0043] The track ring gear 2 is fixedly sleeved on the workbench 1, and the top side and the bottom side of the workbench 1 are ring-shaped with limit grooves, and a plurality of limit sliders 3 are slidably installed in the two limit grooves. Block 3 can be any metal block in the prior art.

[0044] The sides of every two limit sliders 3 that are far away from each other are fixedly installed with the same sliding abutment 4 that is movably socketed on the workbench 1, and the sliding abutment 4 can be any metal platform structure in the prior art , a plurality of sliding bases 4 are provided with arc-shaped teeth 5 , and the arc-shaped teeth 5 match the size of the sliding base 4 .

[0045] One side of the plurality of arc-shaped teeth 5 is fixedly installed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com