Copper wire automatic production line

An automatic production line and copper wire technology, which is applied in the field of copper wire production line, can solve the problems of low equipment automation, reduce labor intensity, and high labor intensity, and achieve the effects of improving work efficiency, reducing labor intensity, and reducing the difficulty of coiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

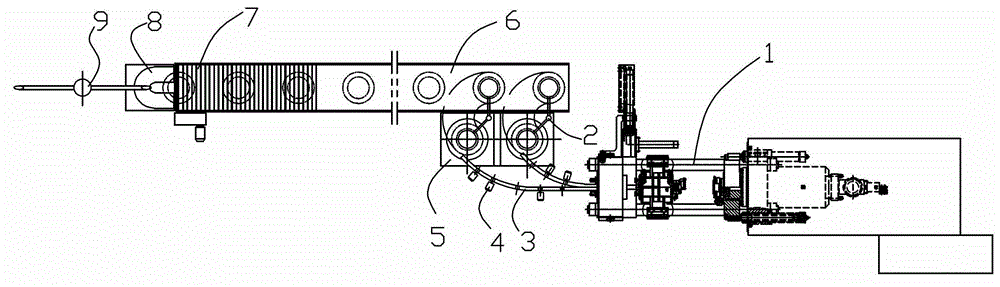

[0025] Embodiment: a kind of copper wire automatic production line (see attached figure 1 ), including extrusion equipment 1, double diversion mechanism 3, coil equipment 5, material transfer equipment 2, cooling equipment 6, receiving equipment 8 and collection equipment 9 placed in sequence. The double diversion mechanism connects the extrusion equipment and the coiling equipment, one end of the double diversion mechanism is connected to the outlet of the extrusion equipment, and the other end is connected to the coiling equipment. The material shifting equipment is between the coiling equipment and the cooling equipment, the receiving equipment is at the end of the cooling equipment, and the collecting equipment is behind the process of the receiving equipment.

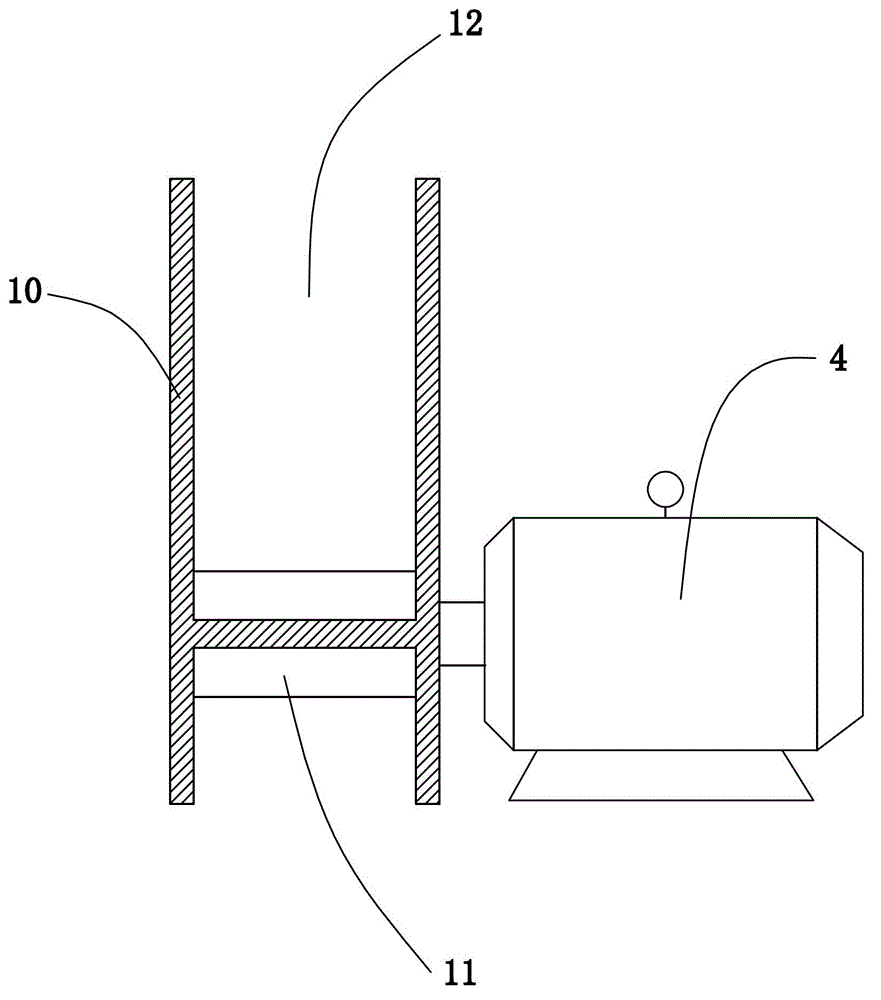

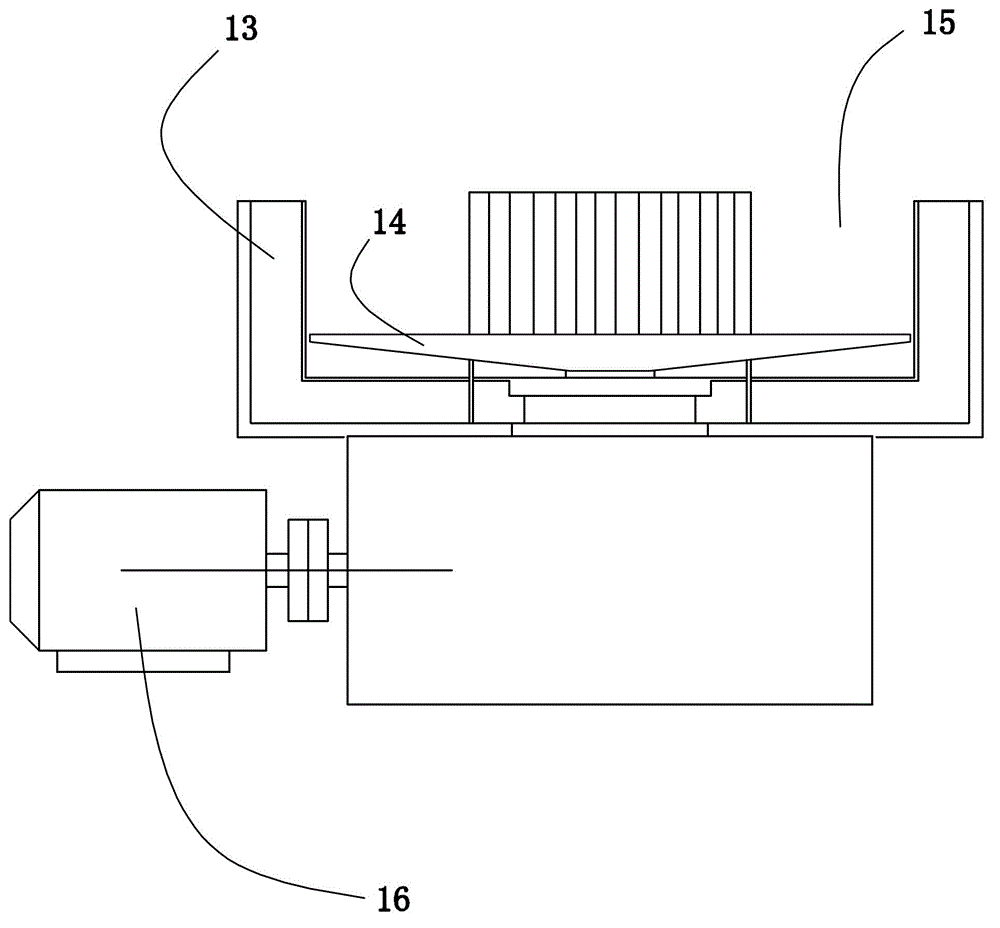

[0026] The straight line direction of the exit of the extruding device deviates from the axis of the coiling device, and the coiling device has two coiling grooves 13 for placing copper wire slabs. Double diversio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com