Multifunctional high-altitude working platform

An aerial work platform, multi-functional technology, applied in the direction of lifting device, portable lifting device, hoisting device, etc., can solve the problems of few types of aerial work platforms, inconvenient movement and operation, frequent adjustment and positioning, etc. The effect of weight reduction and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

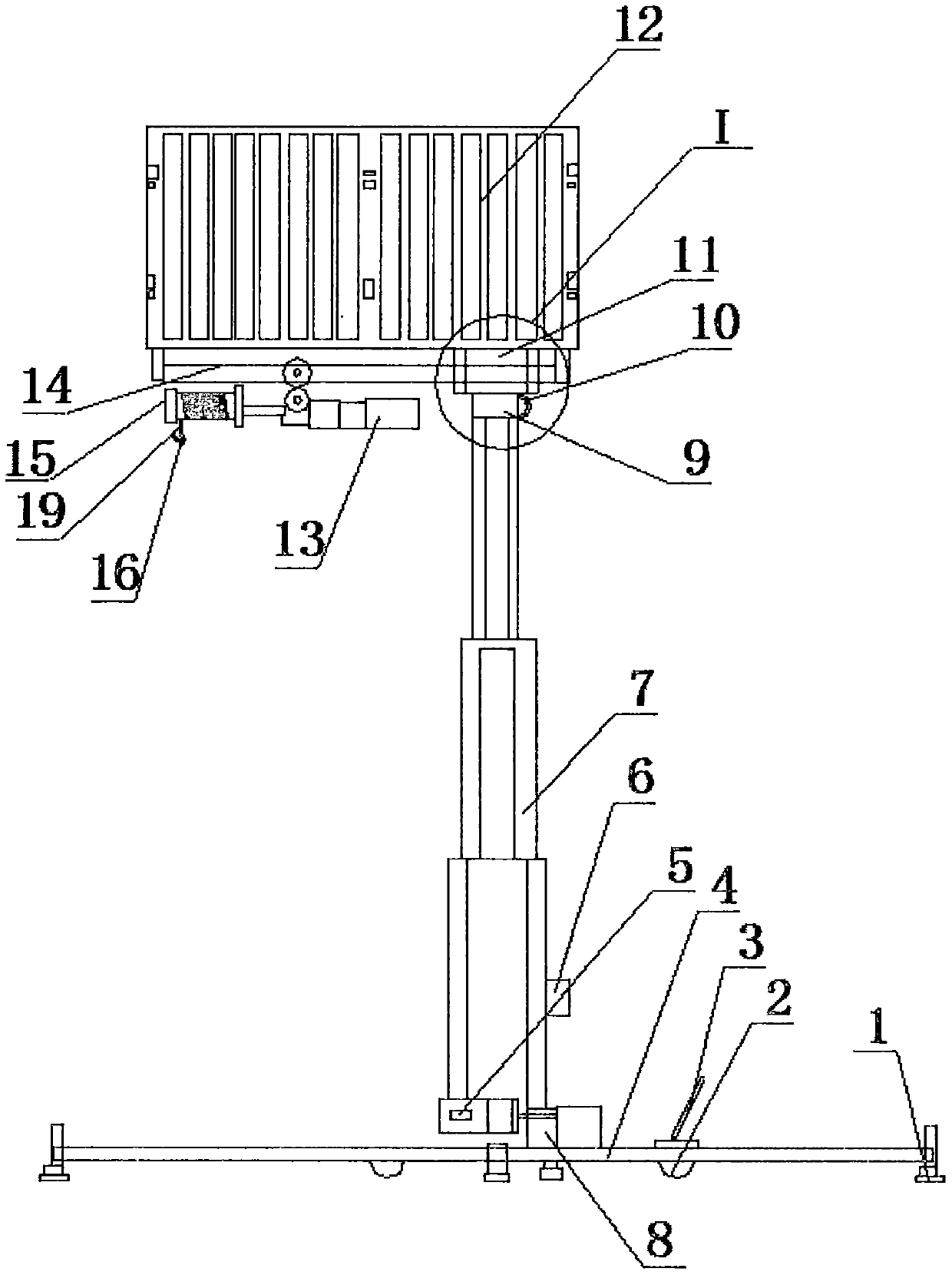

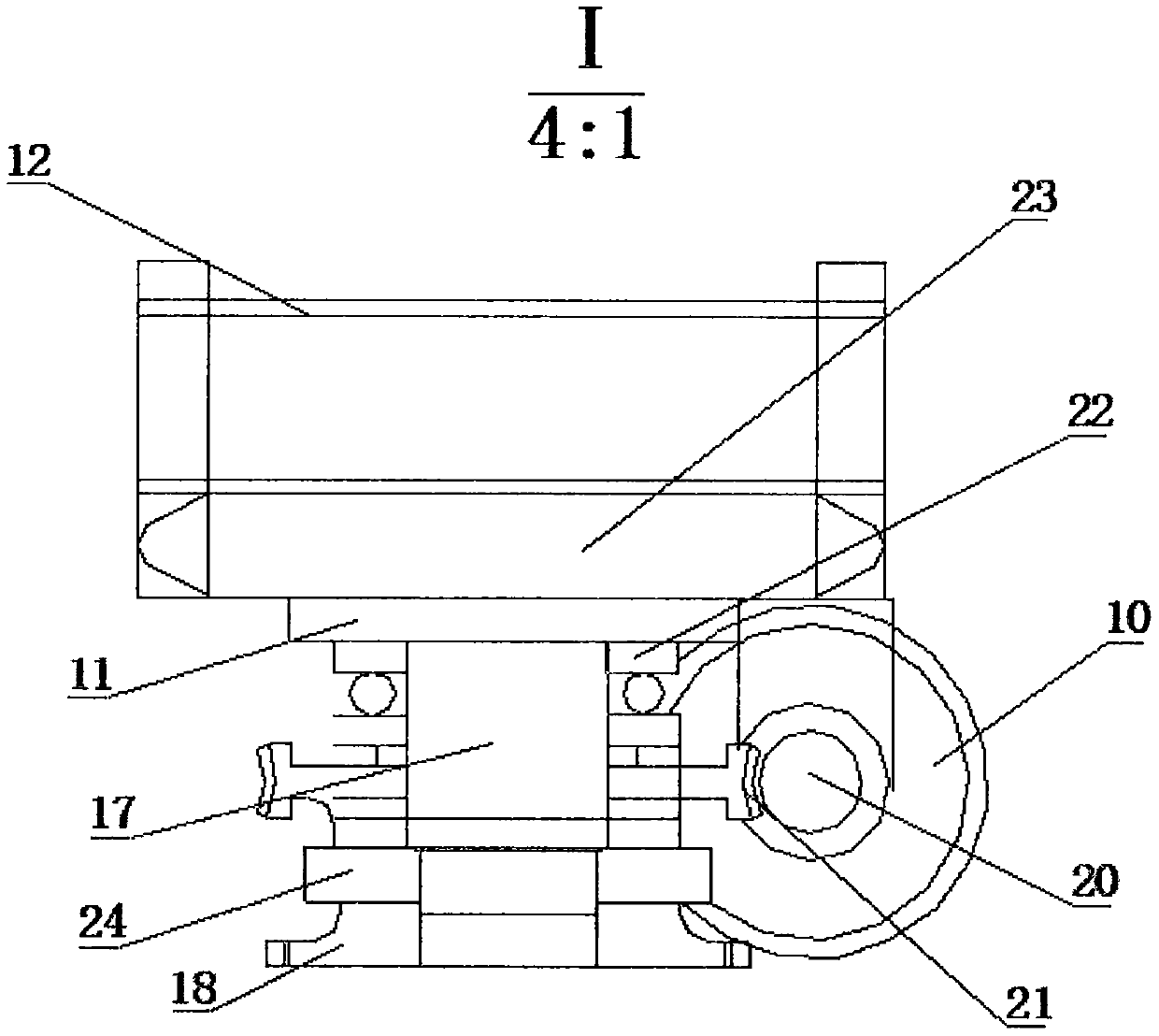

[0016] Such as figure 1 and figure 2 As shown, a multifunctional aerial work platform includes a chassis 4, a leg 1 is arranged under the chassis 4, a wheel 2 is arranged under the chassis 4, and the upper part of the right side wheel 2 is connected with The reversing rod 3, the center of the chassis 4 is provided with a motor A5, a hydraulic pump 8 and a telescopic column 7, the telescopic column 7 is provided with an electric control cabinet 6, and the telescopic column 7 is a secondary hydraulic support rod , the cylinder body of the telescopic column 7 is connected to the chassis 4, the top of the secondary pole of the telescopic column 7 is connected with a flange 25, and a worm gear 21 is arranged between the crossbeam 11 and the secondary pole Mechanism 9, a protective railing 12 is arranged above the beam 11, a reel support 14 is connected below the beam 11, a motor C13 is connected below the reel support 14, and the output shaft of the motor C13 is connected to The...

Embodiment 2

[0019] Such as figure 1 and figure 2 As shown, a multifunctional aerial work platform includes a chassis 4, a leg 1 is arranged under the chassis 4, a wheel 2 is arranged under the chassis 4, and the upper part of the right side wheel 2 is connected with The reversing rod 3, the center of the chassis 4 is provided with a motor A5, a hydraulic pump 8 and a telescopic column 7, the telescopic column 7 is provided with an electric control cabinet 6, and the telescopic column 7 is a secondary hydraulic support rod , the cylinder body of the telescopic column 7 is connected to the chassis 4, the top of the secondary pole of the telescopic column 7 is connected with a flange 25, and a worm gear 21 is arranged between the crossbeam 11 and the secondary pole Mechanism 9, a protective railing 12 is arranged above the beam 11, a reel support 14 is connected below the beam 11, a motor C13 is connected below the reel support 14, and the output shaft of the motor C13 is connected to The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com