Polymer functional graphene and preparation method and application thereof

A polymer, graphene technology, applied in graphene, chemical instruments and methods, carbon compounds, etc., can solve problems such as poor stability, limited stabilization effect, and affected performance, and achieve excellent dispersion stability and generation methods. Simple and convenient, the effect of increasing dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

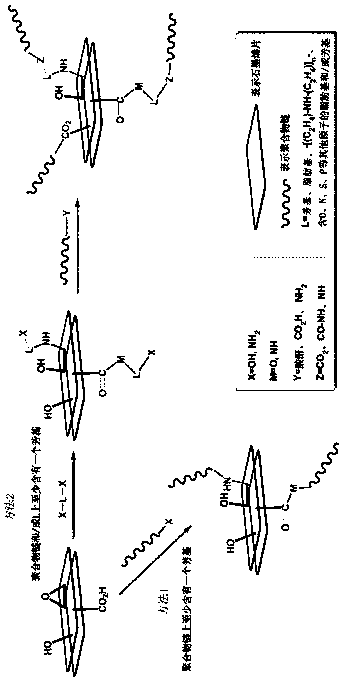

[0045] see figure 2 As shown, in some more specific embodiments, the preparation method includes:

[0046] Reaction of graphene with succinic anhydride and / or succinic acid containing at least one benzene ring in the molecular chain and / or amination of graphene first, and then reacting with succinic anhydride and / or succinic acid containing at least one benzene ring in the molecular chain , thereby obtaining the polymer functionalized graphene.

[0047] Alternatively, succinimide and / or succinamide and / or succinic carboxylate containing amine and / or hydroxyl reactive groups containing at least one benzene ring in the molecular chain are directly reacted with graphene to obtain the Polymer functionalized graphene.

[0048] The application of the polymer functionalized graphene is also provided in the embodiment of one aspect of the present invention.

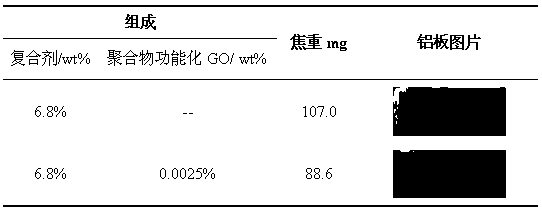

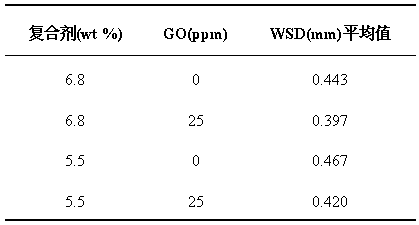

[0049] A typical use of the polymer-functionalized graphene of the present invention is as an additive in lubricating oil c...

Embodiment 1

[0053] Preparation of Polyisobutylene Succinimide Functionalized Graphene

[0054] The polyisobutylene succinimide is prepared according to Example 3 in US20080103075A1, wherein the aromatic amine used is p-aminodiphenylamine, and the polymer is linked with an amine active functional group after the reaction.

[0055] Put 0.05g of graphene oxide into 150ml of THF / DMF (THF:DMF=5:1) mixed solvent, and ultrasonically disperse for 12h to disperse the graphene oxide in the solvent. Add 1.25 g of the self-made polyisobutylene succinimide, stir and disperse at room temperature for 1 h, then gradually raise the temperature to 90° C. while stirring, and react for 24 h. Then slowly add 25g of base oil (150N), and stir at 60°C for 4h. The reaction is stopped, the precipitated graphene oxide is removed by centrifugation, and the solvent is removed from the centrifugal liquid under reduced pressure to obtain graphene functionalized with polyisobutylene succinimide.

[0056] Take part of ...

Embodiment 2

[0061] Preparation of maleic anhydride-functionalized graphene grafted with ethylene-propylene copolymer

[0062] Ethylene-propylene copolymer grafting maleic anhydride is a commercially available product (model g-18, maleic anhydride grafting rate 1.18%, Nanjing Plastic Tai Polymer Technology Co., Ltd.), reacted with p-aminodiphenylamine and alcohol amine , After the reaction, the polymer is connected with a hydroxyl active functional group.

[0063] Put 0.05g graphene into 150ml xylene / DMF (xylene:DMF=5:1) mixed solvent, and ultrasonically disperse for 12h to fully disperse graphene oxide. Add 1.25 g of the self-made ethylene-propylene copolymer containing hydroxyl active functional groups, stir and disperse at room temperature for 1 h, then gradually raise the temperature to 90°C while stirring, and react for 24 h. Then slowly add 25g of base oil (150N), and stir at 80°C for 4h. The reaction is stopped, the precipitated graphene oxide is removed by centrifugation, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com