Hanging floating type trash holding device

A floating and trash rack technology, applied in the field of metal structures of water conservancy and hydropower projects, can solve the problem of easy jamming of trash racks, and achieve the effects of less investment, convenient installation, maintenance, and convenient cleaning and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

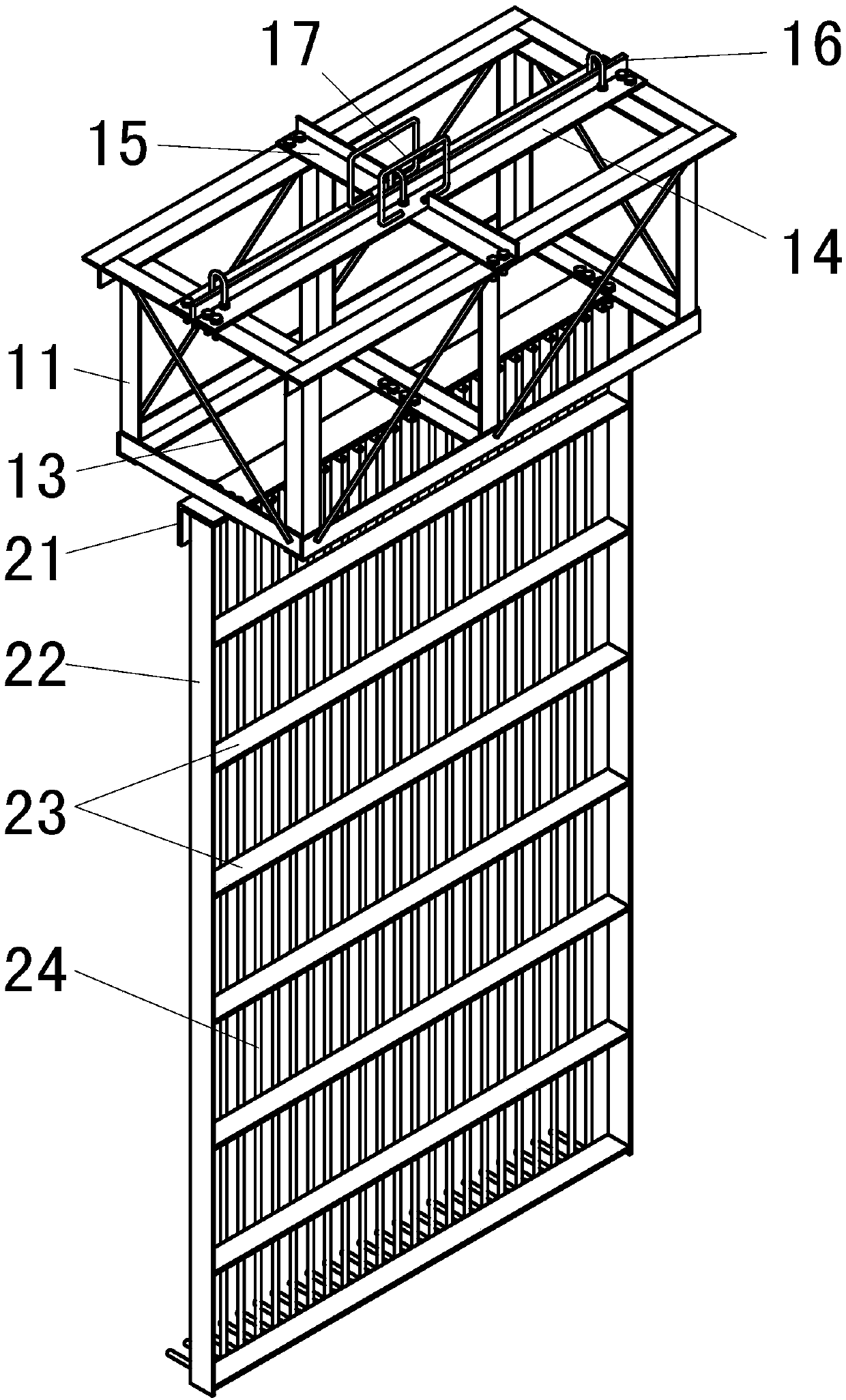

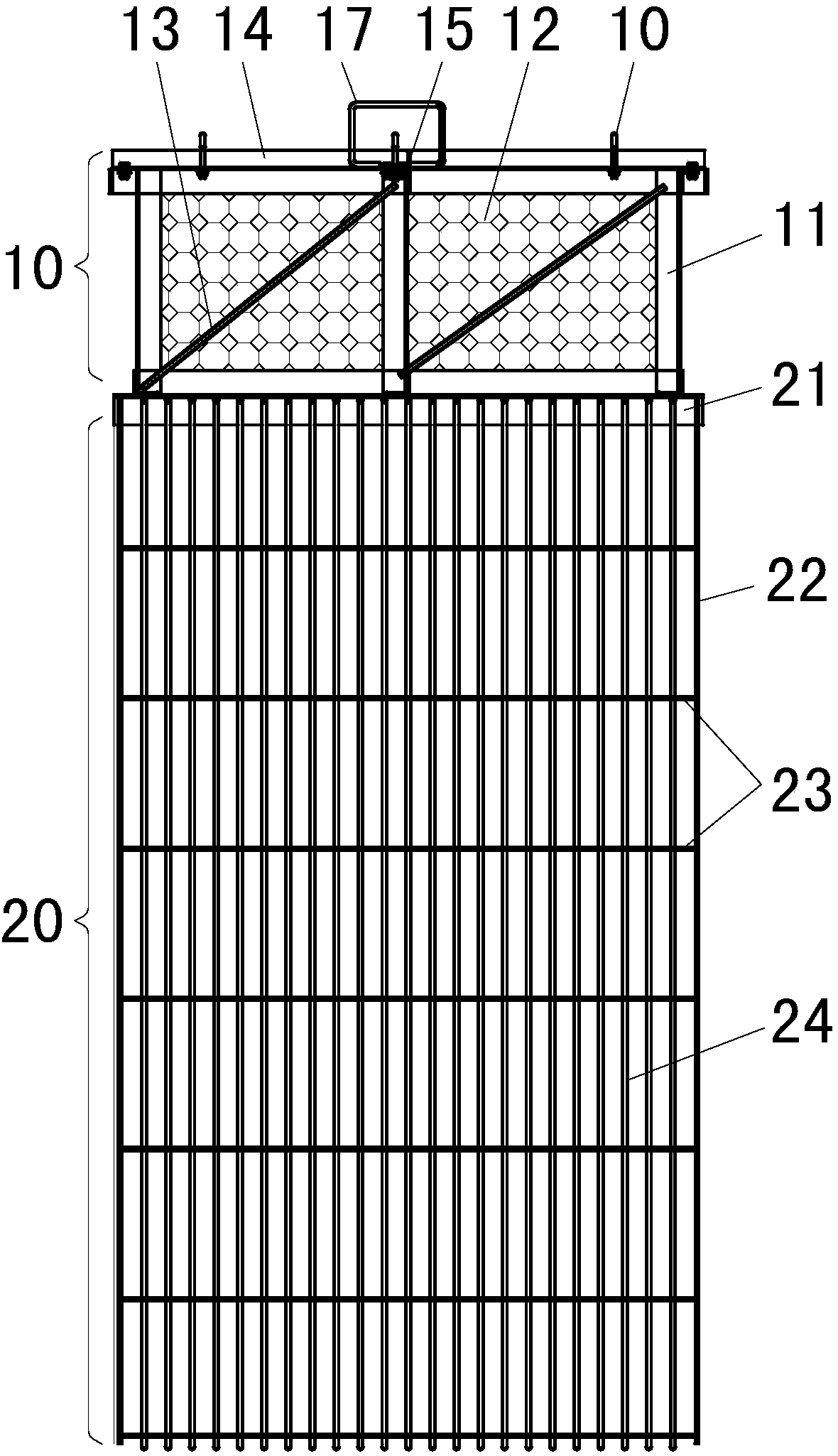

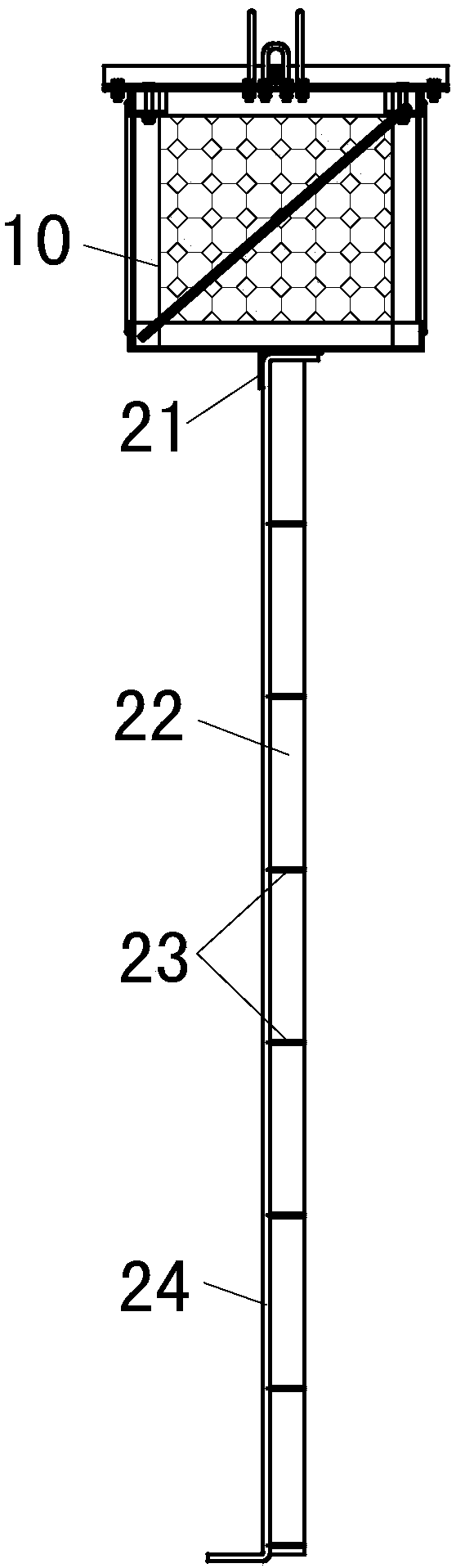

[0035] Suspension floating type trash arresting device of the present invention, as Figure 1-6 As shown, it consists of a group of trash-blocking units suspended on the hinge seats 05 on both sides of the forebay 01 of the non-pressure diversion hydropower station or the outlet of the grit chamber through the steel wire rope 04, and the trash-stopping unit is fixed on the hinges on both sides of the outlet end through the steel wire On the seat 05, the upper part of the trash blocking unit is a floating assembly 10, and the floating assembly 10 includes a cuboid frame 11, which is welded by angle steel. Plastic foam 12 is placed in the cavity of cuboid frame 11, and plastic foam 12 is sealed by angle steel or round steel 10 welded on cuboid frame 11 around, to prevent plastic foam 12 from protruding from around cuboid frame 11. The lower part of the rectangular parallelepiped frame 11 is sealed by the supporting angle steel 21 on the top of the trash rack assembly 20 to preve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com