Convenient and fast type roadbed tamping machine

A tamping machine, a portable technology, applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of difficult disassembly and maintenance, increased working time, and increased road construction costs, so as to achieve convenient disassembly and maintenance , improve the overall progress, improve the effect of maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

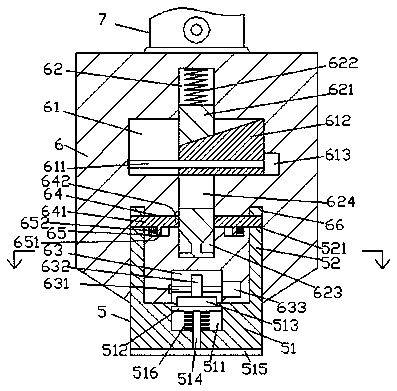

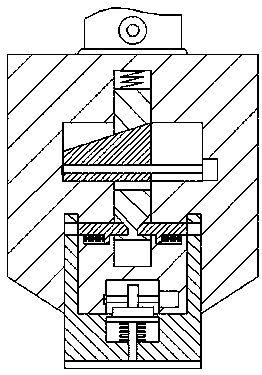

[0017] Such as Figure 1-Figure 4 As shown, a portable subgrade compacting machine of the present invention includes a tamping device with a boom 7 installed at the bottom of the boom 7, and the tamping device includes an upper body 6 and a tamping device for mating with the upper body 6 The lower body 5 is provided with a sinking groove 63 in the bottom end surface of the upper body 6, and the inner wall of the upper body 6 on the upper side of the sinking groove 63 is provided with a first sliding cavity 61 extending left and right. A second sliding cavity 62 extending up and down is formed in the middle of the cavity 61, and a lifting slider 621 is slidably connected in the second sliding cavity 62, and the second sliding block on the top of the lifting slider 621 A first spring 622 is connected to the cavity 62 with pressure fit. The middle position inside the lifting slider 621 is provided with an inclined-plane through chute 624. The top pressure inclined chute 623 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com