Filter tube and super-soft soil solidifying device provided with same

A curing device and ultra-soft soil technology, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of poor vacuum transfer effect, vacuum degree consumption, and waste of electric energy at the connection parts, and achieve enhanced transfer effect and depth , avoid the loss of vacuum degree, and enhance the effect of treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

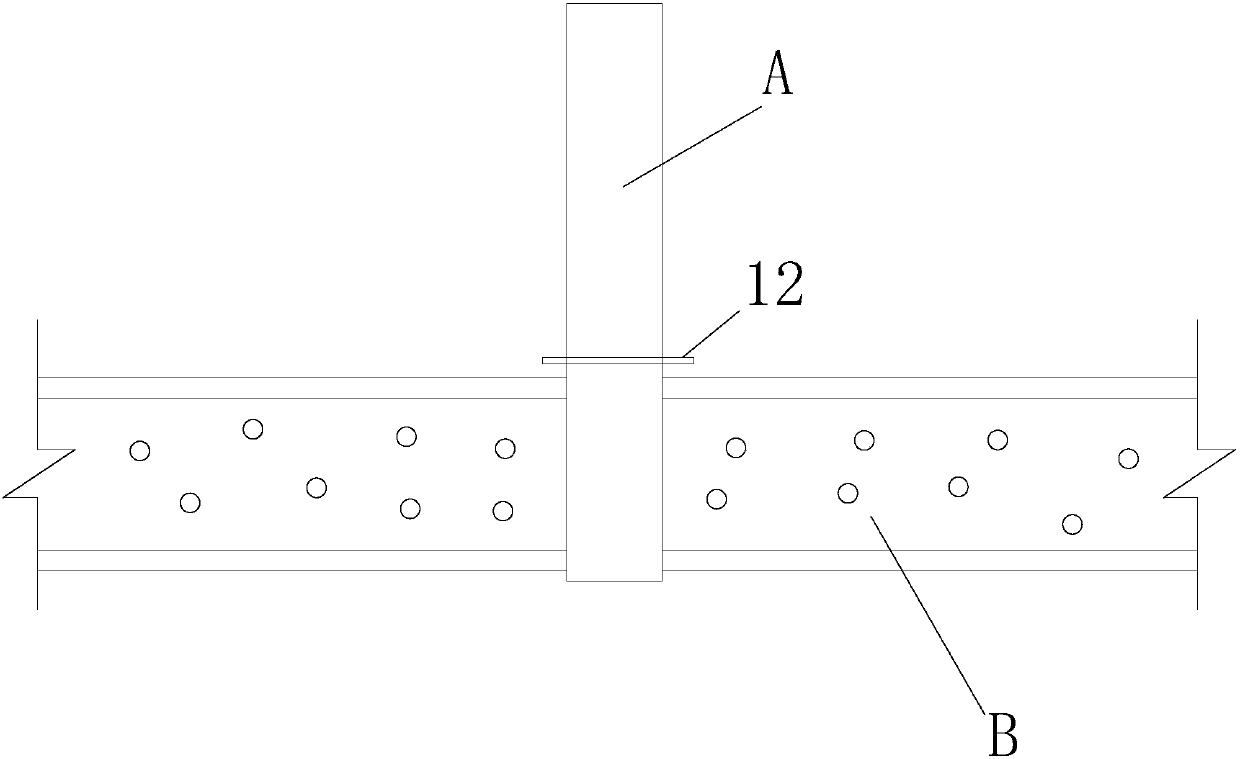

[0036] Figure 4 to Figure 7 A specific embodiment of the ultra-soft soil curing device of the present application is shown. The same as the traditional soft soil curing device, the soft soil curing device of this embodiment also includes: a drainage board, a filter pipe connected to the drainage board , a vacuum device connected to the filter tube.

[0037] The key improvement of this embodiment is that the above-mentioned drainage plate, filter pipe and vacuuming equipment all adopt a new type of structure, and the connection method between the drainage plate and the filter pipe is also improved. details as follows:

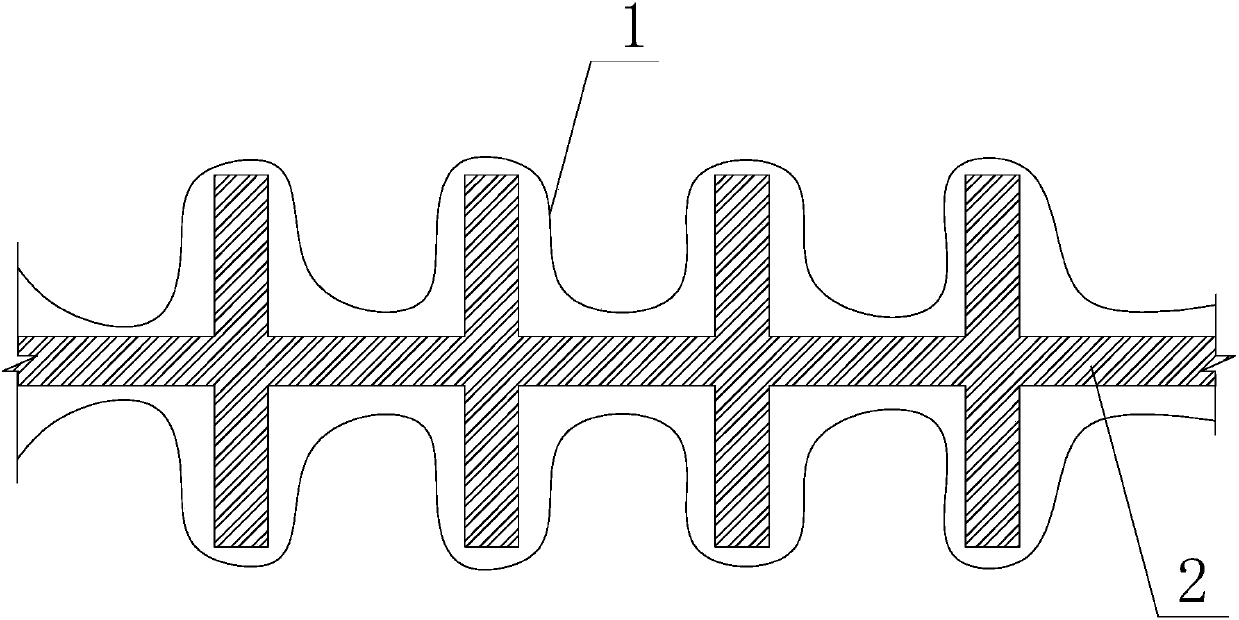

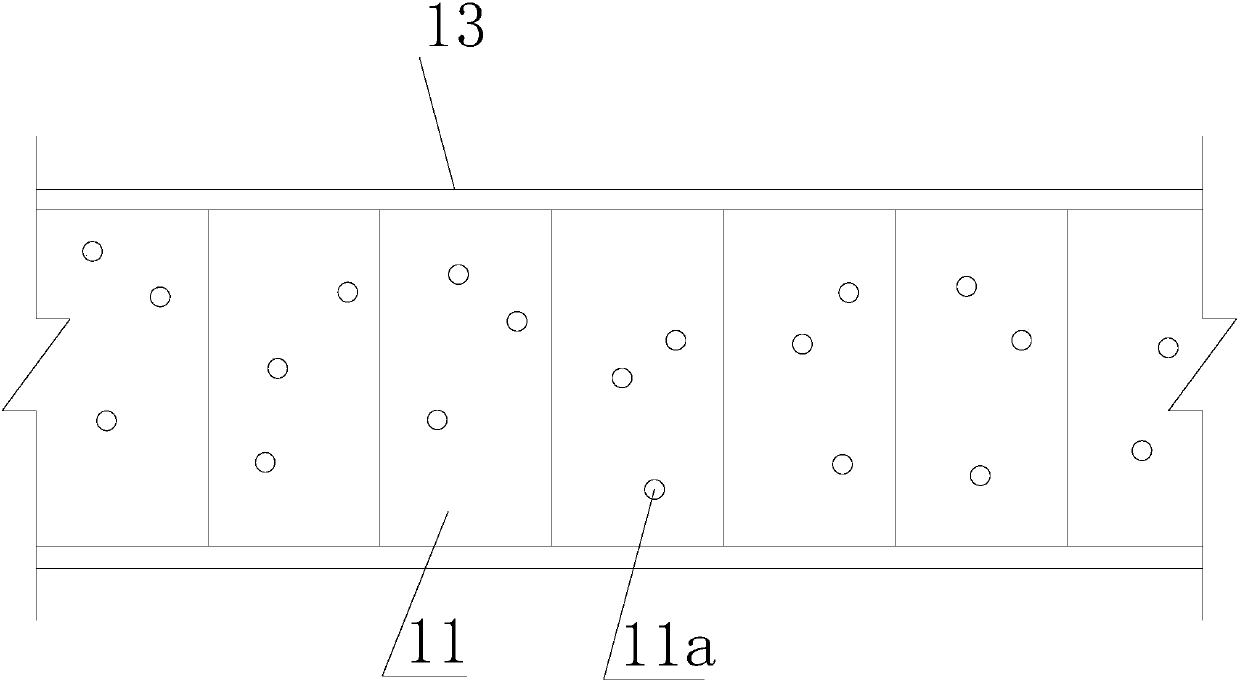

[0038] First, the drainage pipe in this embodiment also includes a plate core 2, a filter membrane 1 and a drainage channel 3 formed between the plate core and the filter membrane, and the plate core 2 is a multi-cross structure. The main improvement of the drainage pipe is that the plate core 2 and the filter membrane 1 are fixedly connected together in a ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com