Prefabricated basement pipeline module and manufacturing method thereof

A production method and basement technology, applied in the direction of building components, buildings, building structures, etc., can solve problems such as water leakage, inability to pour in place, and steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

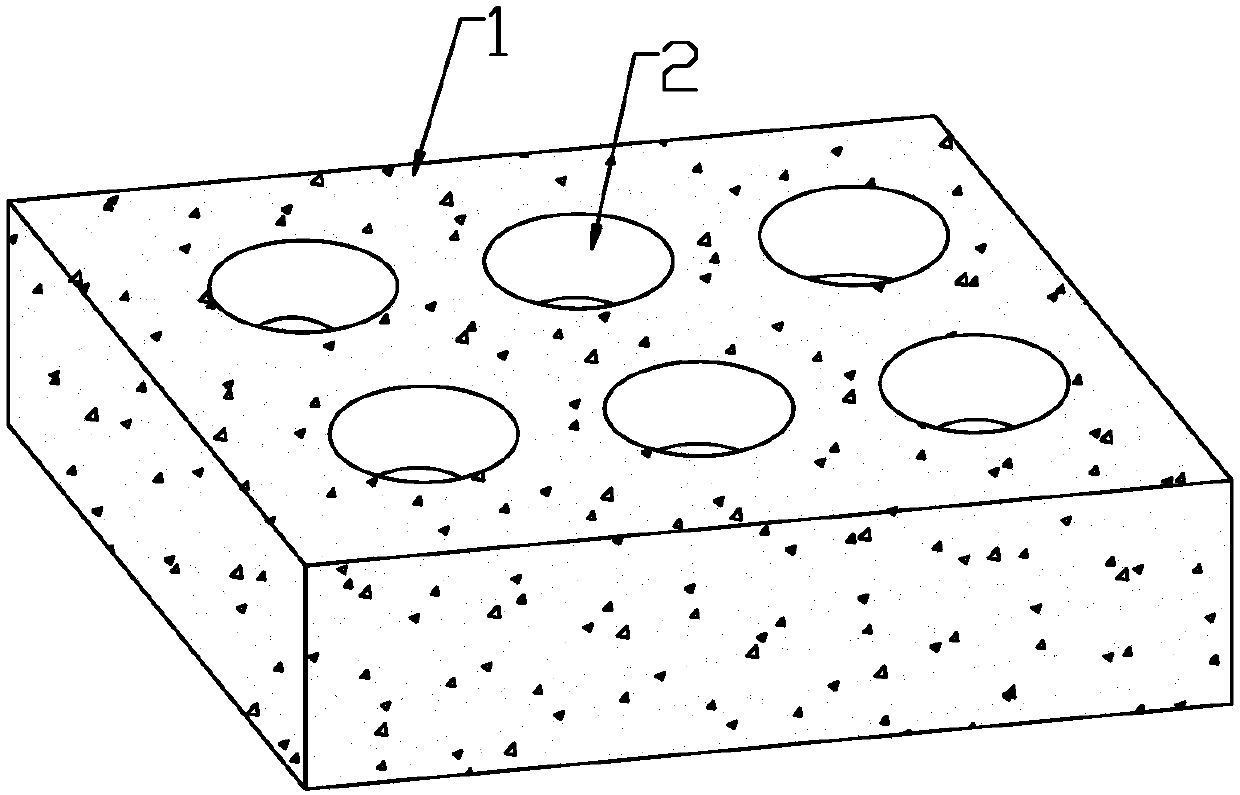

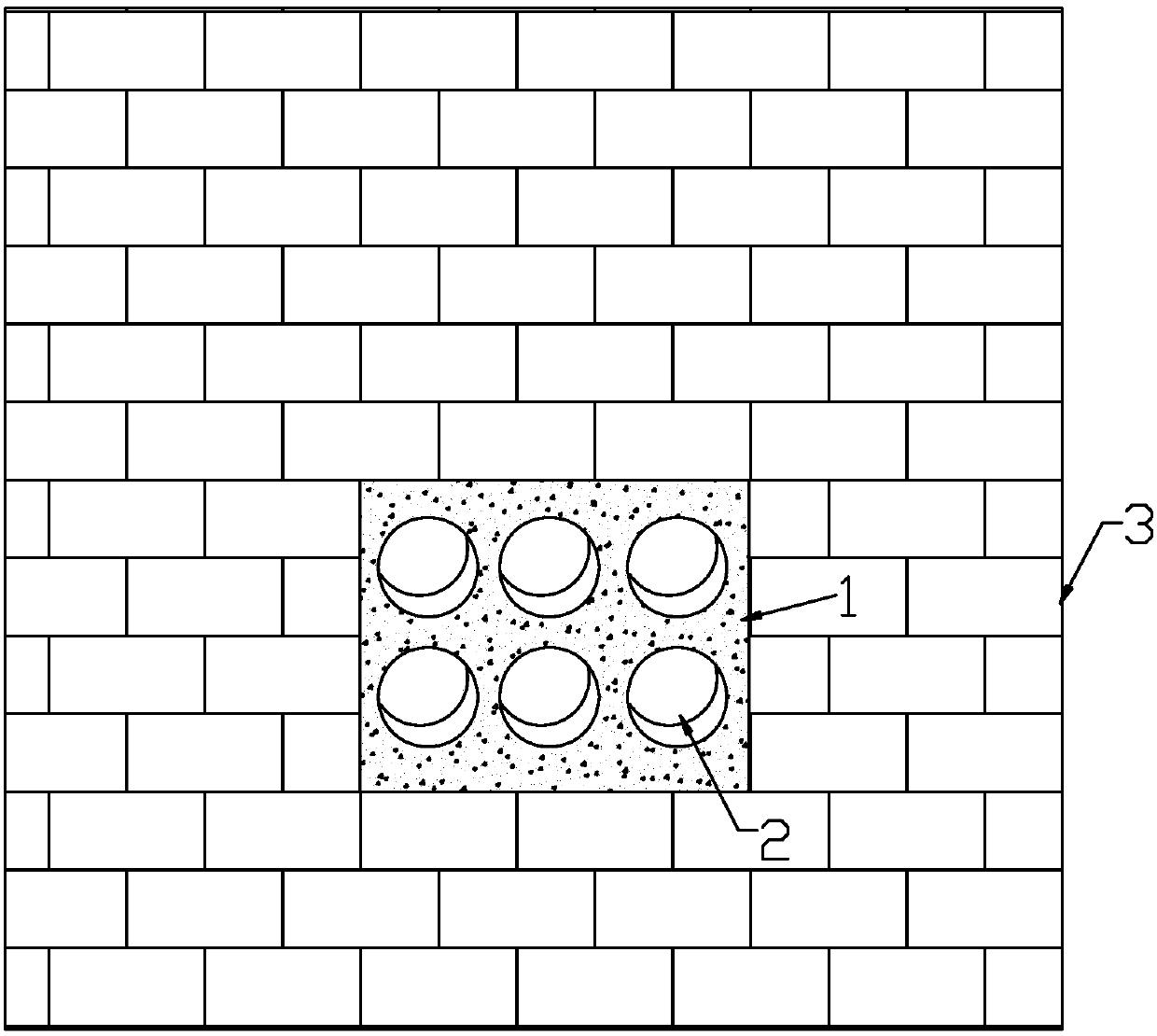

[0012] The module will be described in detail below in conjunction with the accompanying drawings, such as Figure 1-2 The prefabricated basement piping module shown provides a complete node structure and is specially used to replace the part of the basement wall piping connection to avoid water leakage and ensure construction quality.

[0013] The thickness of the prefabricated basement pipeline module 1 is the same as that of the basement wall 3; several through holes 2 are arranged on the module 1. Specifically, the size of the through holes 2 is adapted to the pre-installed pipes, and the number and distribution of the through holes 2 are the same as the designed pipes at this node of the wall.

[0014] This module designs the pouring mold of the module according to the prefabricated wall specifications. The module is prefabricated before the wall is built. The module is designed into the wall and its installation position is determined.

[0015] The production method of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com