Truss steel bar structure integrated with structural steel bars and construction method

A technology of steel bars and trusses, applied in the field of truss steel bars and construction, can solve the problems of polluting the environment, wasting resources, and low strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

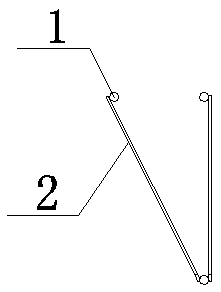

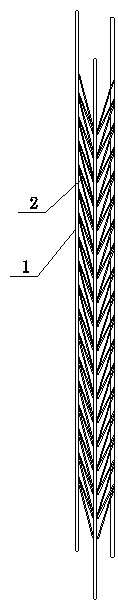

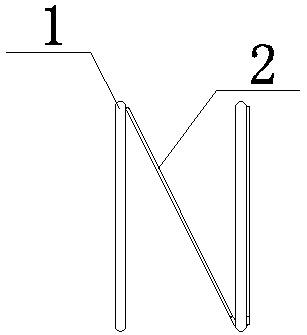

[0028] A truss reinforcement integrated with structural reinforcement, comprising: a set of corrugated reinforcement 2, a set of structural reinforcement 1, the truss reinforcement consists of a set of corrugated reinforcement and a set of structural reinforcement A welded one-piece structure, the heights of the crests of the corrugated steel bars are equal, the heights of the troughs of the corrugated steel bars are equal, and the crests of the corrugated steel bars and the corrugated steel bars The troughs of each wave are respectively welded to the structural steel bars.

Embodiment 2

[0030] According to the truss reinforcement integrated with structural reinforcement described in Embodiment 1, the angles between each crest of the corrugated reinforcement and each trough of the corrugated reinforcement are 30-150 degrees.

Embodiment 3

[0032] According to the truss reinforcement integrated with structural reinforcement described in Embodiment 1 or 2, the included angle between two adjacent corrugated reinforcements is 0-90 degrees.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com