Hydraulic oil cooling structure

A technology of cooling structure and hydraulic oil, applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, mechanical equipment, etc., can solve the problems of increasing, frequent failure of hydraulic equipment, unstable operation of hydraulic equipment, etc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

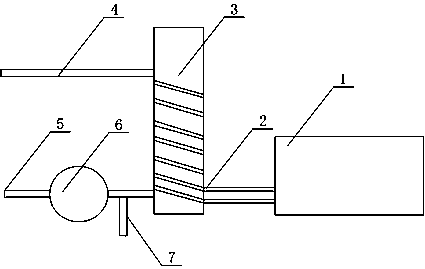

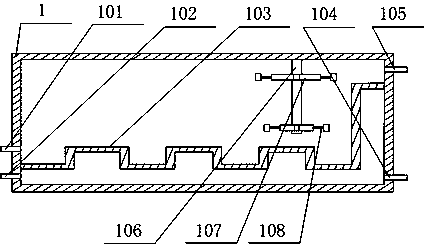

[0021] like figure 1 and figure 2 As shown, this embodiment includes a water tank 1 and a heat exchange cylinder 3, the upper and lower ends of the heat exchange cylinder 3 are respectively connected with a liquid outlet pipe 5 and a liquid return pipe 4, and a cooling pipe is respectively opened on the lower section of the side wall at one end of the water tank 1. Liquid outlet 101, hot liquid inlet 102, the upper section of the side wall at the other end of the water tank 1 has a cold liquid inlet 105 and its lower section has a hot liquid outlet 104, and the cold liquid outlet 101 communicates with the hot liquid inlet 102 through the heat exchange tube 2, And the heat exchange tube 2 is spirally wound on the outer peripheral wall of the heat exchange tube 3 along the axial direction, and a corrugated plate 103 is installed in the box to divide it into two parts, and the corrugated plate 103 is far away from the cooling liquid outlet One end of 101 is bent and then extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com