Boiler tail gas waste heat recovery device and recovery method based on split-flow heating technology

A technology for waste heat recovery equipment and boilers, applied in lighting and heating equipment, heat exchange equipment, heat exchangers, etc., can solve problems such as heat pollution, energy waste, and environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

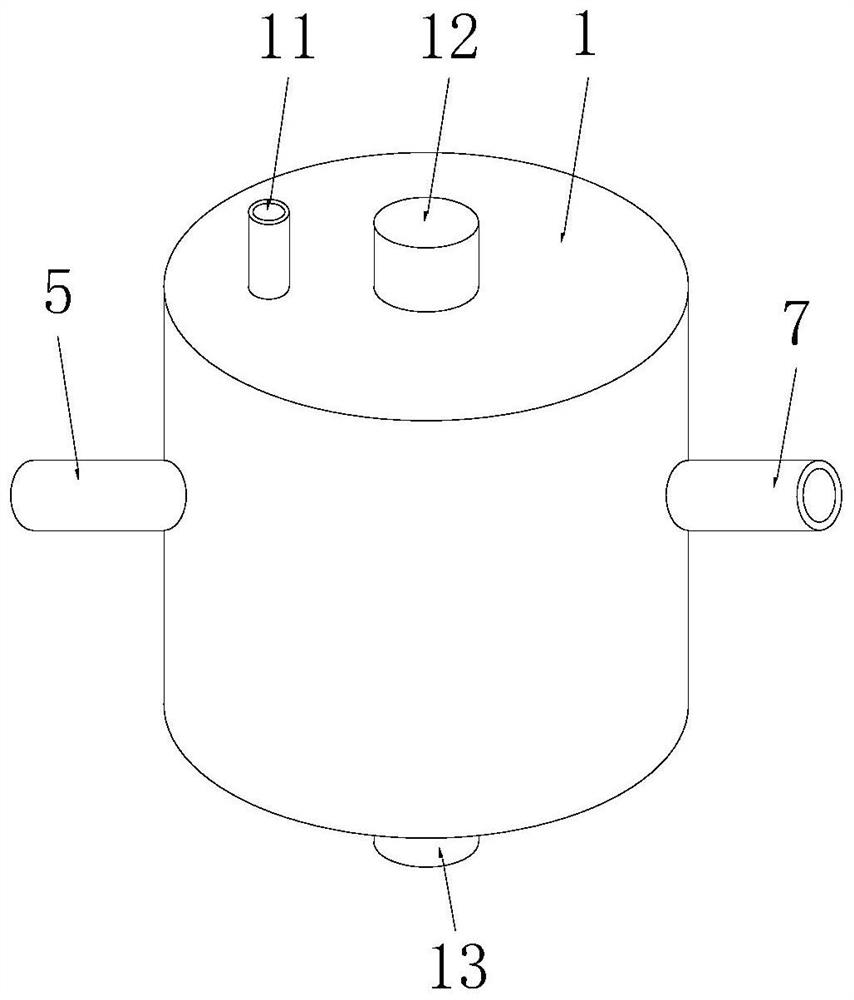

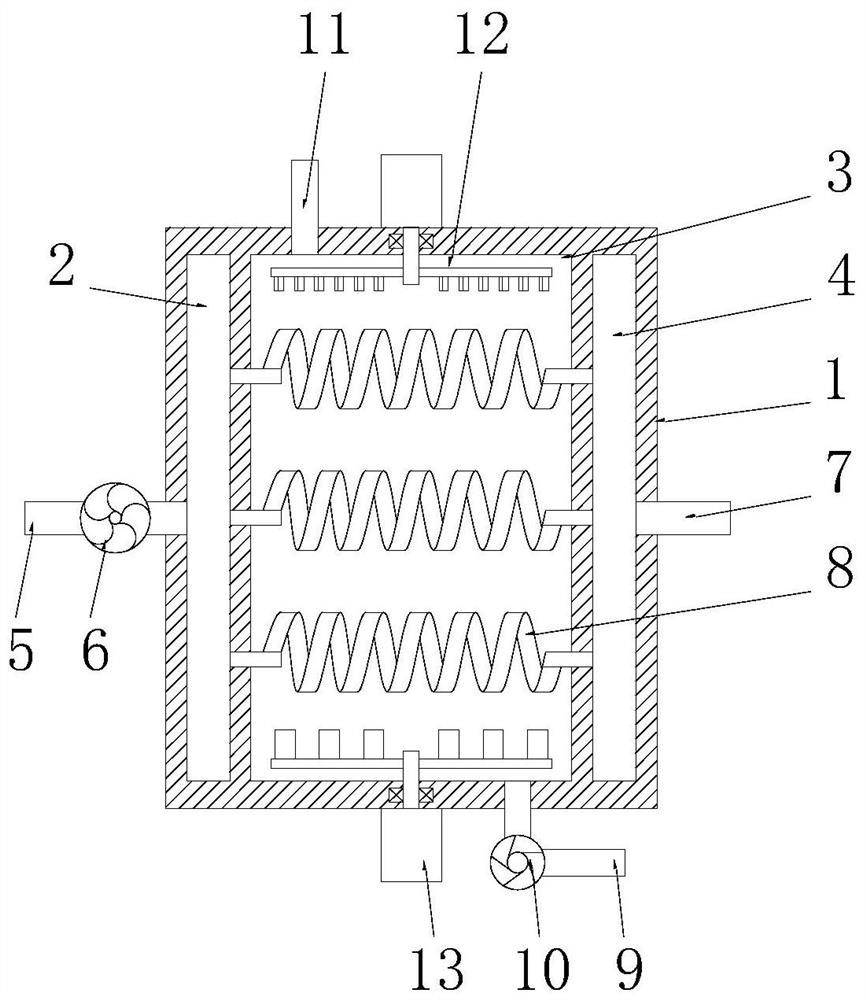

[0032] See Figure 1-2 , a boiler tail gas waste heat recovery device based on split heating technology, comprising an exchange box 1, the exchange box 1 is a cylindrical structure, the exchange box 1 is provided with an air intake chamber 2, a heat exchange chamber 3 and an air outlet chamber 4, The heat exchange chamber 3 is located in the middle of the exchange box 1, the air inlet chamber 2 and the air outlet chamber 4 have the same structure, the air inlet chamber 2 and the air outlet chamber 4 are arc-shaped chambers, and the air inlet chamber 2 and the air outlet chamber 4 are symmetrically arranged on the left and right sides of the heat exchange chamber 3, one end of the air inlet chamber 2 is connected to the inlet pipe 5, and the air intake pump 6 is installed on the inlet pipe 5, and one end of the air outlet chamber 4 is connected to the outlet pipe. Air pipe 7, a number of heat exchange tubes 8 are evenly arranged in the heat exchange chamber 3, the heat exchange...

Embodiment 2

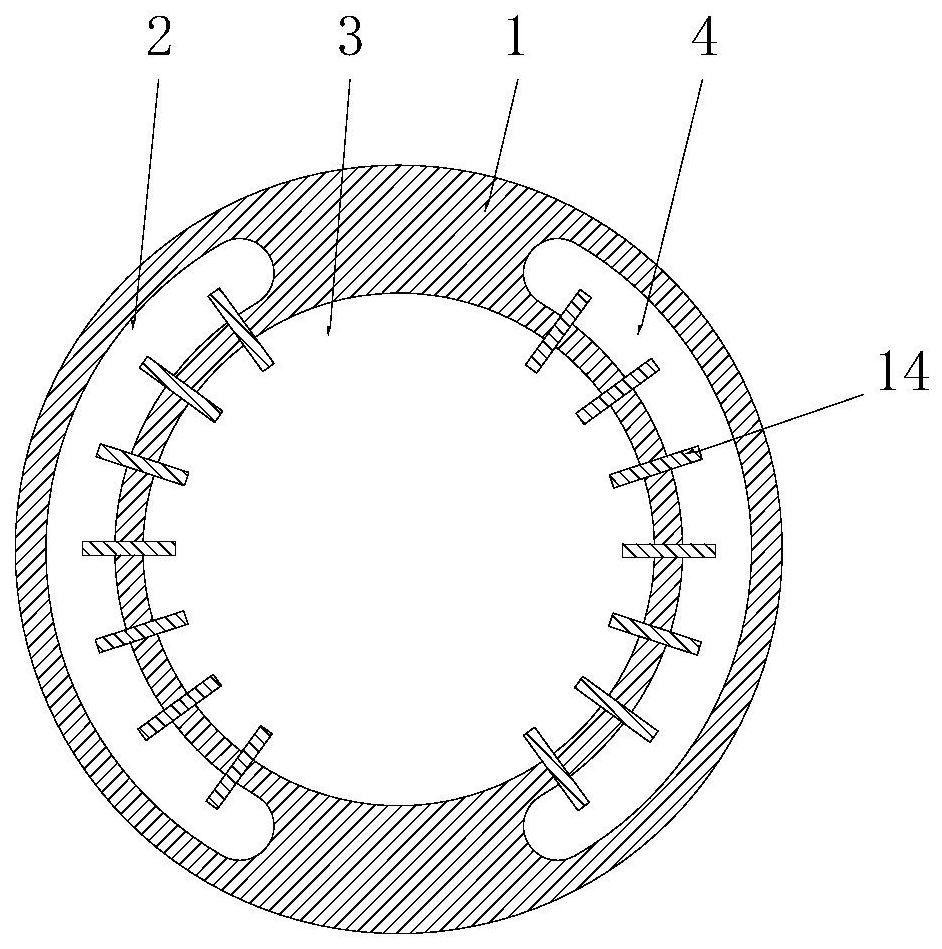

[0036] See Figure 3-4 The difference from Example 1 is that: the side wall of the heat exchange chamber 3 is evenly embedded with a number of heat exchange fins 14 that match the air outlet chamber 4, and the heat exchange fins 14 include two substrates 141 , the substrate 141 is a corrugated structure, the substrate 141 is made of aluminum alloy material, and a plurality of second connecting plates 143 and a plurality of first connecting plates 142 are arranged between the two substrates 141, all of the The second connection plates 143 are arranged side by side in parallel, all the first connection plates 142 are arranged in parallel, the relationship between the first connection plates 142 and the second connection plates 143 is perpendicular to each other, and the heat exchange fins 14 are The heat exchange chamber 3 and the air inlet chamber 2 or the air outlet chamber 4 are connected by two substrates 141, and then the waste heat in the auxiliary boiler exhaust gas and t...

Embodiment 3

[0038] See Figure 5-6 The difference from Embodiment 1 is that the first stirring mechanism 12 includes a first motor 121 and a first stirring shaft 122, the first motor 121 is fixedly connected to the top of the exchange box 1, and the first stirring shaft 122 is located in the heat exchange chamber 3, the axis of the first stirring shaft 122 coincides with the axis of the heat exchange chamber 3, the top of the first stirring shaft 122 penetrates the top wall of the heat exchange chamber 3 and is rotatably connected to the first motor 121, The first stirring shaft 122 is rotatably connected to the exchange box 1 through the first bearing 123, and the outer circular surface of the first stirring shaft 122 is evenly provided with a plurality of first stirring plates 124, and the bottom ends of the first stirring plates 124 are evenly arranged. It is provided with several first stirring blades 125, and the first stirring blades 125 are arranged obliquely, and the side ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com