Chimney protection lining and manufacturing method thereof

A chimney and lining technology, applied in the field of chimney protection lining and its manufacturing, can solve the problems of inability to protect, the construction area and the vertical height of the construction are large, and the construction quality is difficult to guarantee, so as to reduce the construction difficulty and tile rigidity. Large, easy-to-install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

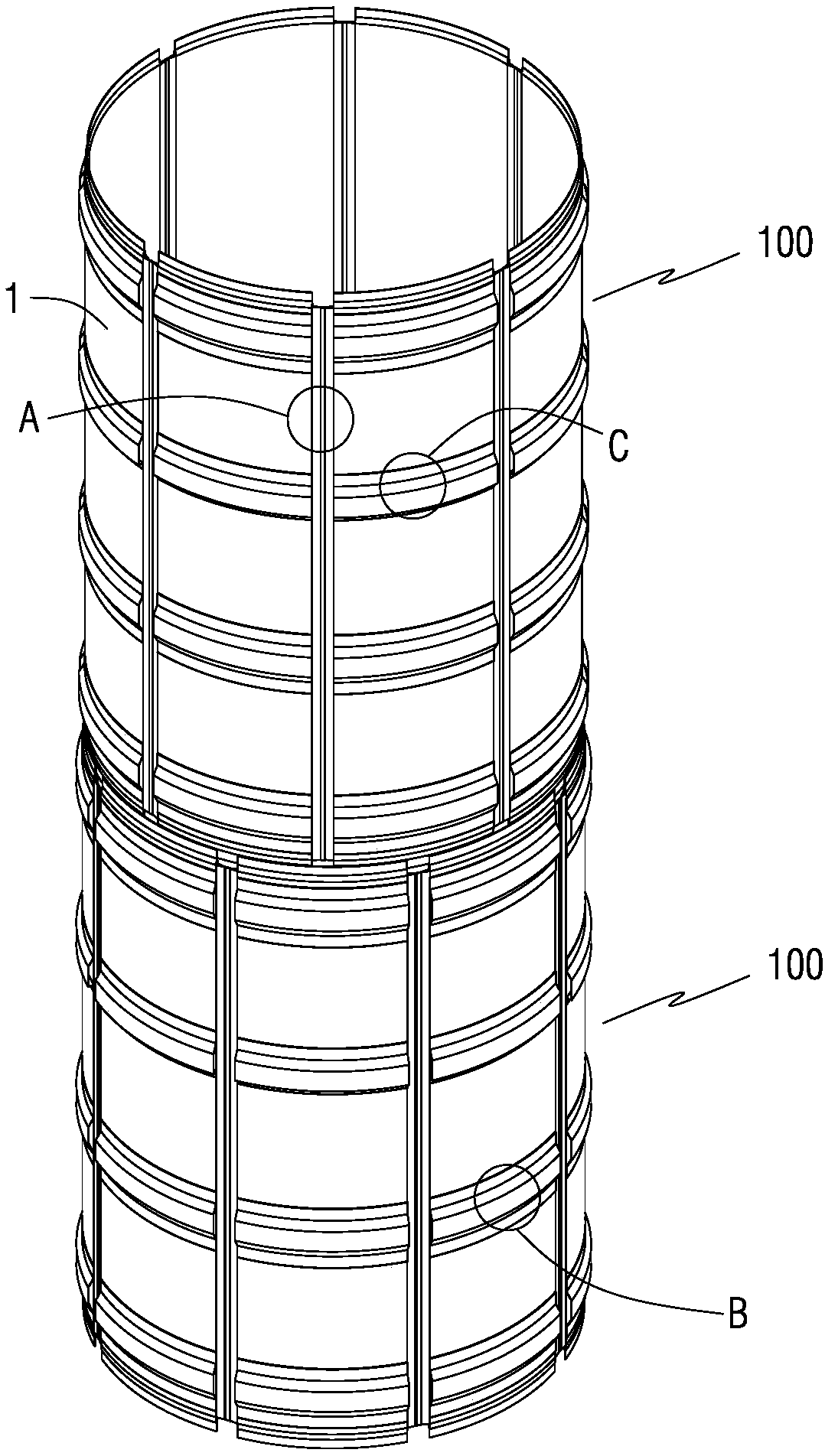

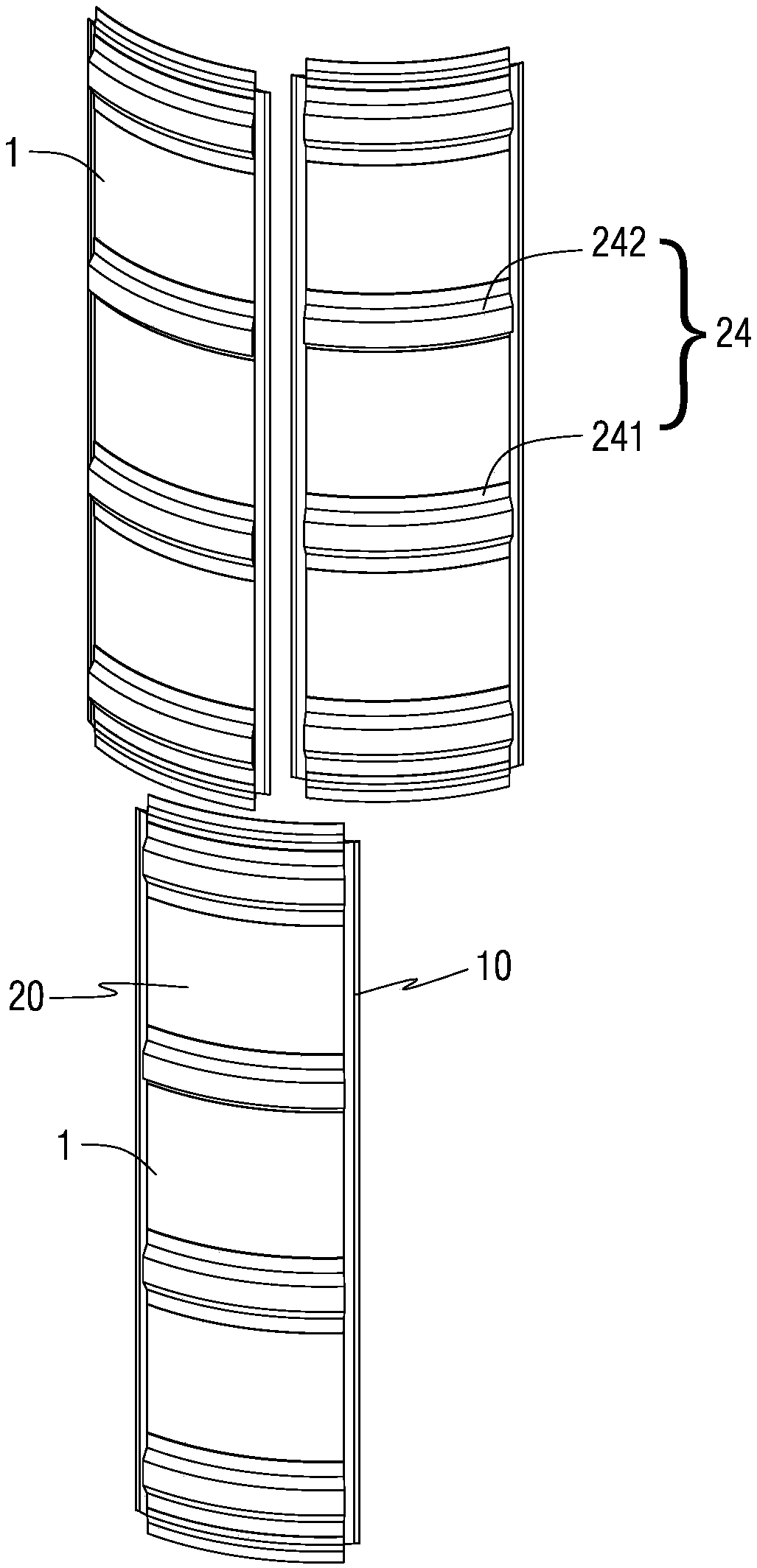

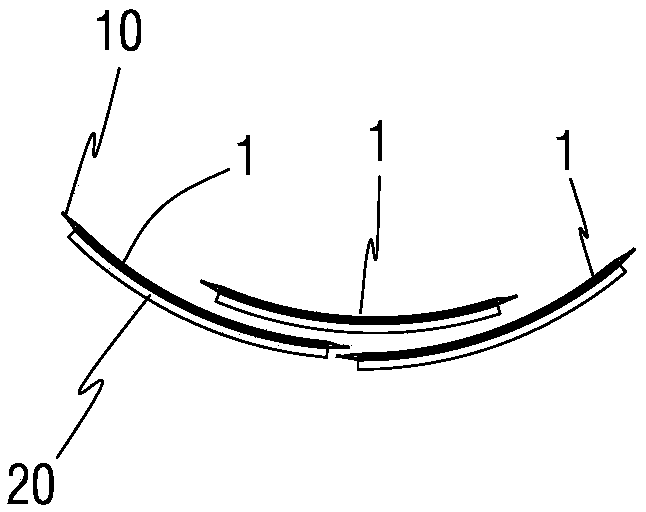

[0027] As mentioned in the background technology section, because the chimney protective lining in the existing anti-corrosion treatment scheme for the inner wall of the chimney of an old coal-fired power plant is formed by attaching or hanging a small piece of glass steel plate to the inner wall of the chimney, the construction is difficult and difficult. The defects of low efficiency and uncheckable construction quality, therefore, the present invention provides a kind of improved chimney protective inner lining, its structure can refer to the attached Figure 1-6 As shown, among them, figure 1 Shown is a schematic diagram of the assembly of a chimney protective lining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com