Automatic waste heat defrosting system for gas heat pump

A gas heat pump and gas engine technology, applied in heat pumps, air conditioning systems, heating methods, etc., can solve the problems of large input equipment, waste heat waste, complex control, etc., and achieve the effects of less waste heat waste, efficient utilization, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

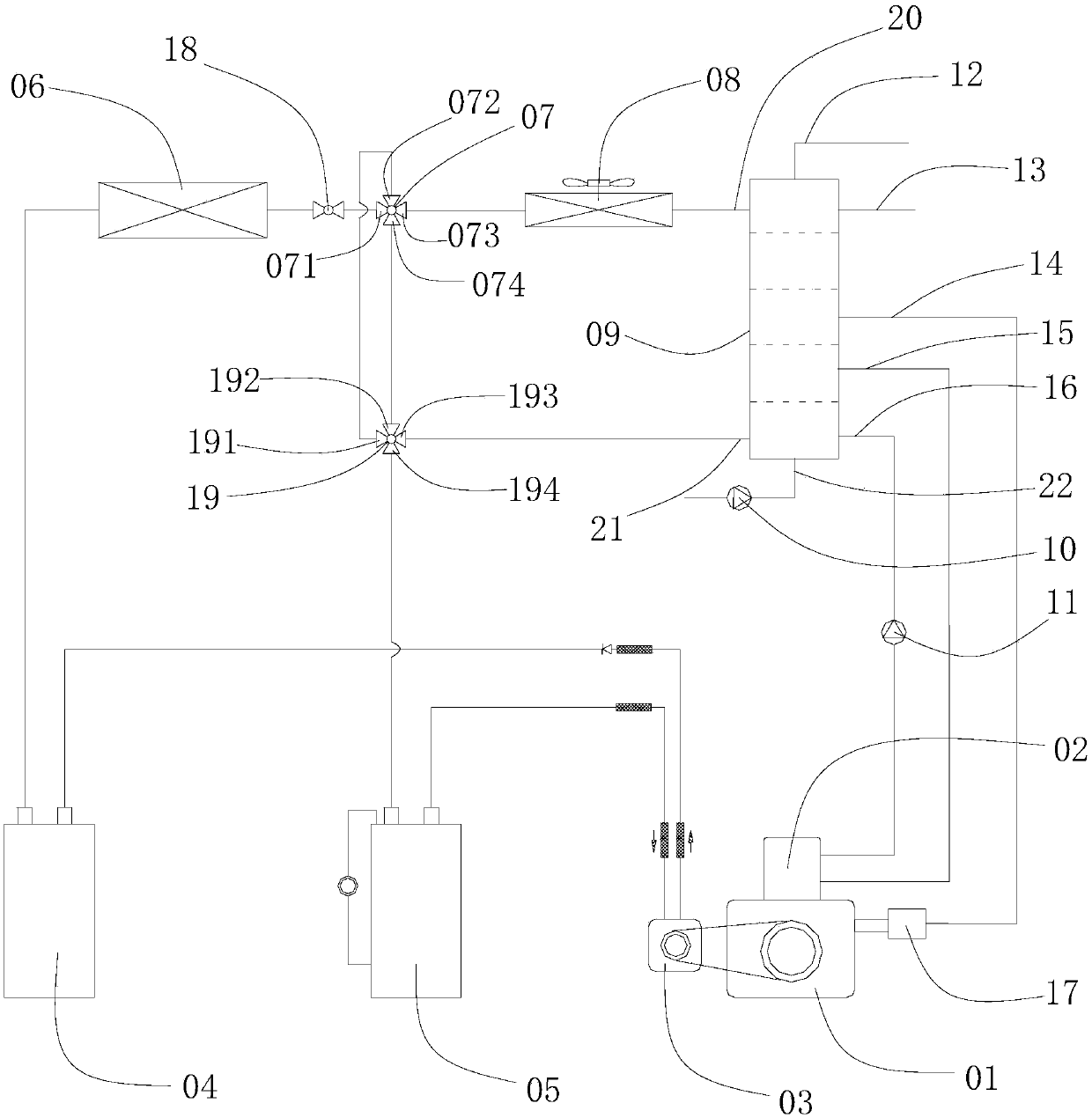

[0017] refer to figure 1 , is a gas heat pump waste heat automatic defrosting system, including a gas engine 01, a cylinder liner waste heat recovery device 02 installed on the gas engine 01, a compressor 03, a gas-liquid separator 05, an oil separator 04, an evaporator 06, Air heat exchanger 08, layered water collection tank 09, jacket cooling water circulation pump 11, first four-way valve 07 and second four-way valve 19; layered water collection tank 09 is equipped with refrigerant inlet 20, refrigeration Agent outlet 21, engine exhaust heat exchange outlet 13, engine exhaust heat exchange inlet 14, cylinder jacket cooling water heat exchange outlet 15, cylinder jacket cooling water heat exchange inlet 16, domestic hot water supply outlet 12, water replenishment inlet 22; cylinder liner waste heat The inlet of the recoverer 02 is connected to the liner cooling water circulation pump 11 and the liner cooling water heat exchange outlet 15 through the pipeline; the outlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com