Drawing force test device and test method for blade root pre-buried bolt sleeve of wind power blade

A technology of wind turbine blades and pre-embedded bolts, which is applied to measuring devices, force/torque/power measuring instruments, instruments, etc., can solve the problems of not being able to test the whole blade, not being able to use on-site testing, and being inflexible in use, and achieve light weight , simple structure and low number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

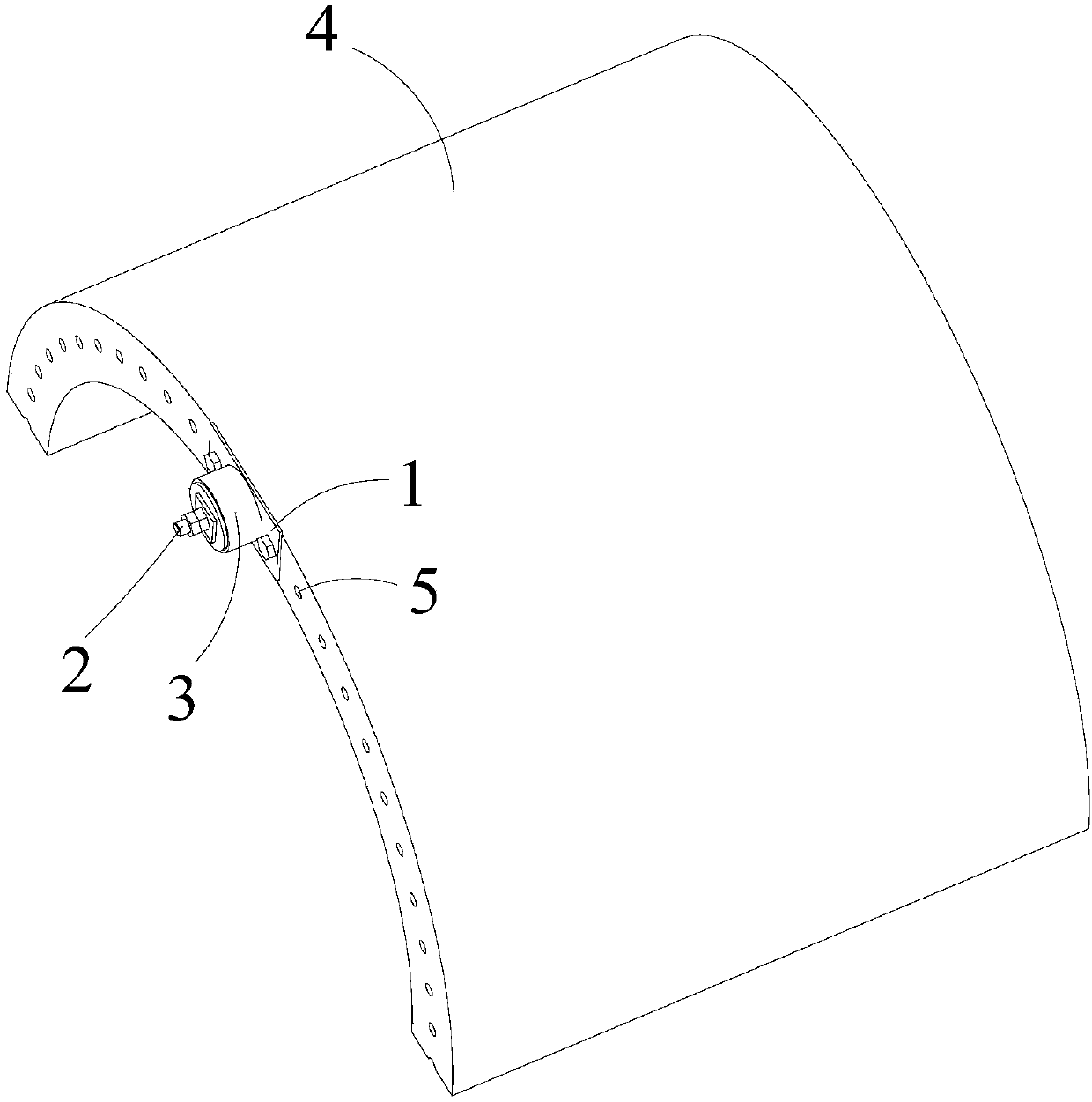

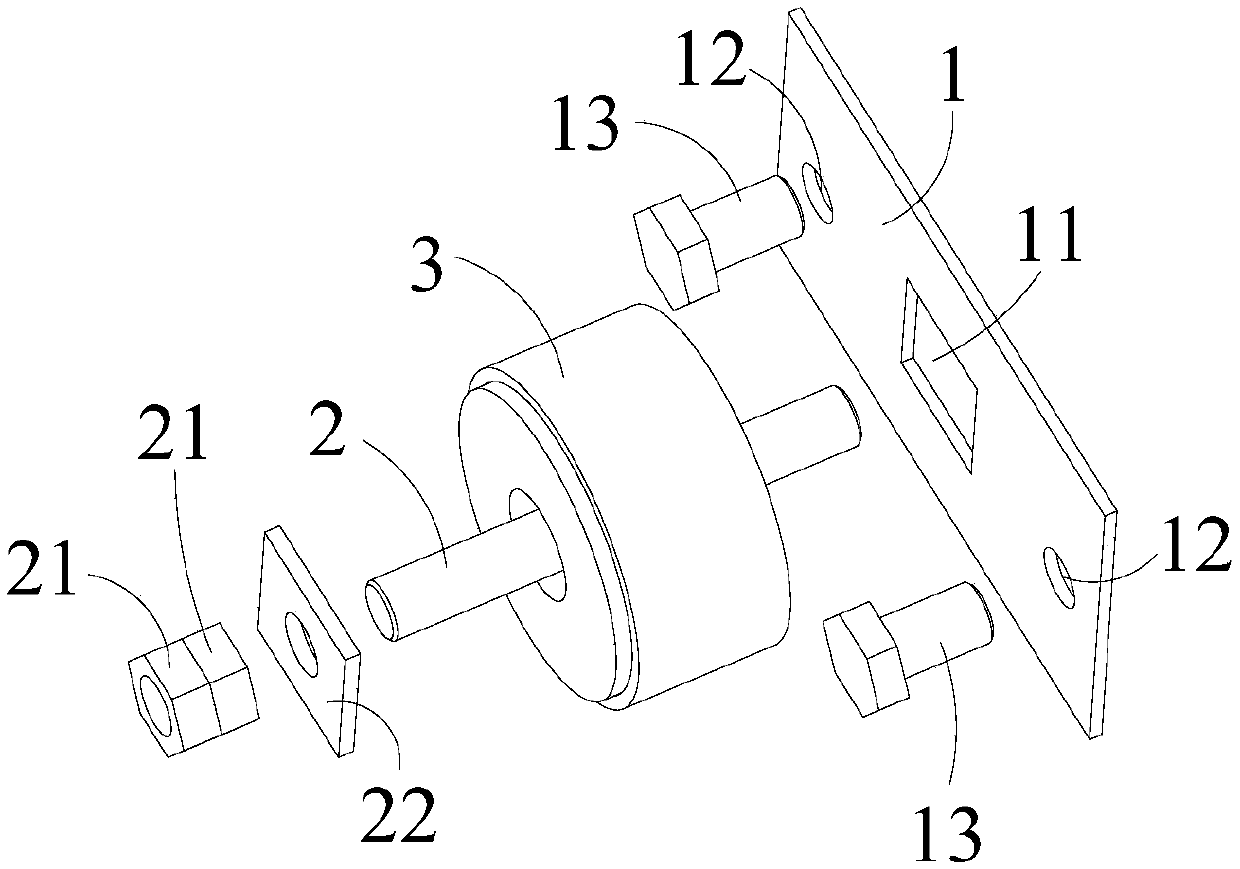

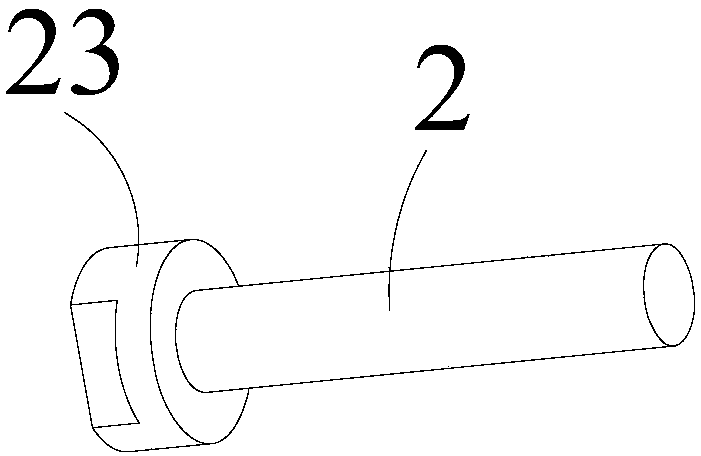

[0030] see figure 1 and figure 2 , the embodiment discloses a wind power blade root embedded bolt sleeve pullout force testing device, which is used for testing the embedded bolt sleeve 5 on the blade root test piece 4 of the wind power blade. The device for testing the pullout force of the pre-embedded bolt sleeve of the blade root of a wind power blade includes a backing plate 1, a tie rod 2, a hollow jack 3 and a pullout force measurement device.

[0031] The backing plate 1 can be a steel plate, and the backing plate 1 can be attached to an end surface of the blade root test piece 4 provided with the bolt sleeve 5 . Through holes 11 for exposing the bolt sleeves 5 are provided on the backing plate 1 . When the backing plate 1 is attached to the end surface of the blade root test piece 4 , the bolt sleeve 5 will not be blocked by the backing plate 1 due to the existence of the through hole 11 , so the bolt sleeve 5 can be tested. The backing plate 1 can also be provided...

Embodiment approach 2

[0042] This embodiment discloses a method for testing the pull-out force of a bolt sleeve embedded in a blade root of a wind power blade, which is used to test the pull-out force of a bolt sleeve embedded in a blade root specimen of a wind power blade, including the following steps:

[0043] A backing plate is provided, and the backing plate is attached to an end surface of the blade root test piece provided with a bolt sleeve, and the backing plate is provided with a through hole for exposing the bolt sleeve;

[0044] A pull rod is provided, and one end of the pull rod passes through the through hole and is threadedly connected with the bolt sleeve;

[0045] Sleeve a hollow jack or a hollow actuator on the pull rod, and make the hollow jack or hollow actuator abut against the backing plate and provide a pulling force to the pull rod;

[0046] The pullout force is measured by a pullout force measuring device.

[0047] The method for testing the pull-out force of the pre-embed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com