Method for accurately measuring evaporated mass in coal

A quality and accurate technology, applied in the direction of weighing by removing certain components, can solve problems such as large errors, low efficiency, and low efficiency of detection methods, and achieve the effects of solving low efficiency, improving detection efficiency, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

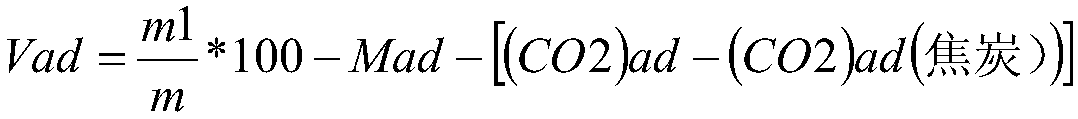

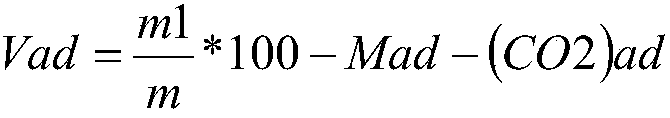

[0022] The method capable of accurately measuring the volatile mass in coal comprises the following steps:

[0023] (1) Selection of equipment: use a porcelain crucible with a tightly fitted cover, and a crucible with a total mass of 15-20g as a volatile crucible; choose a pyrometer and a temperature adjustment device, which can maintain the temperature at 900 ± 10 ℃, and there is a muffle furnace with sufficient constant temperature zone (900±5℃) as the furnace. The heat capacity of the furnace is when the initial temperature is 920 ℃. , and return to 900±10°C within 3 minutes. There is a vent hole on the back wall of the furnace and a small hole for inserting a thermocouple. At 20-300mm from the bottom of the furnace, the constant temperature zone of the muffle furnace should be measured with the furnace door closed, and should be measured at least once every six months, and the pyrometer (including millivoltmeter and thermocouple) should be calibrated at least once every si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com