Analysis method for steam turbine valve flow characteristics on the basis of historical data regression analysis

A regression analysis, valve flow technology, applied in electrical digital data processing, special data processing applications, measuring devices, etc., can solve problems such as poor accuracy, low efficiency of optimized calculation methods, inconsistency between design stroke and actual stroke, etc. The effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

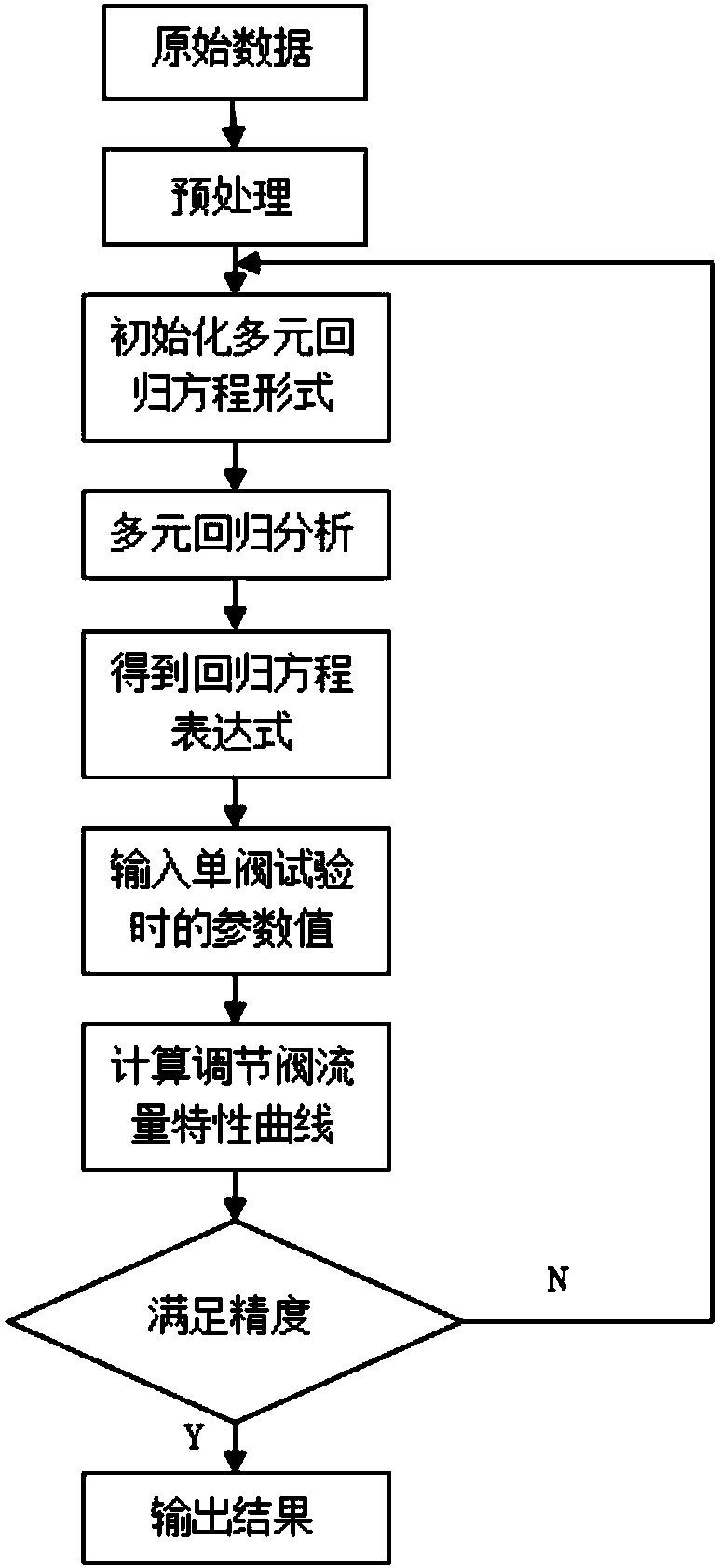

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

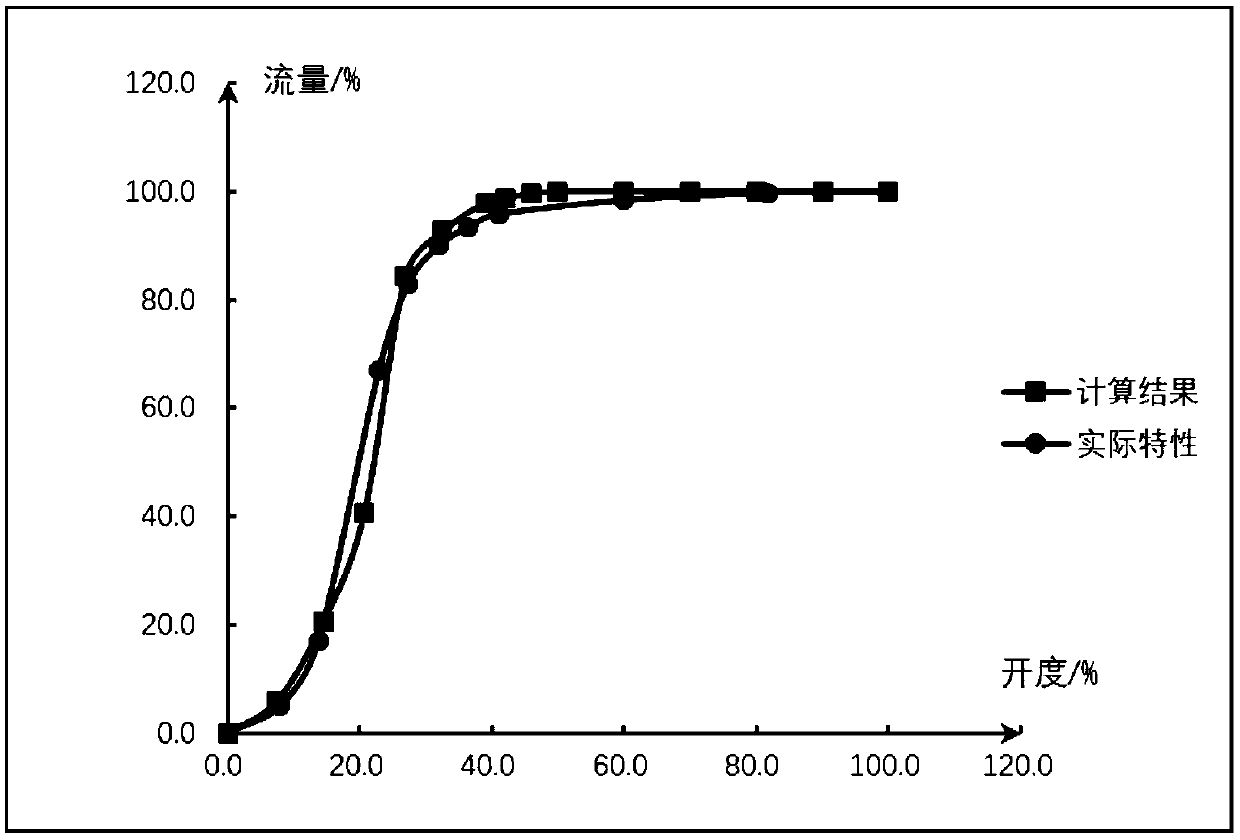

[0021] refer to Figure 1 to Figure 3 In this example, the historical operation data of a supercritical steam turbine unit N660-24.2 / 566 / 566 is used to calculate the flow characteristic curve of the high-pressure regulating valve through multiple regression analysis.

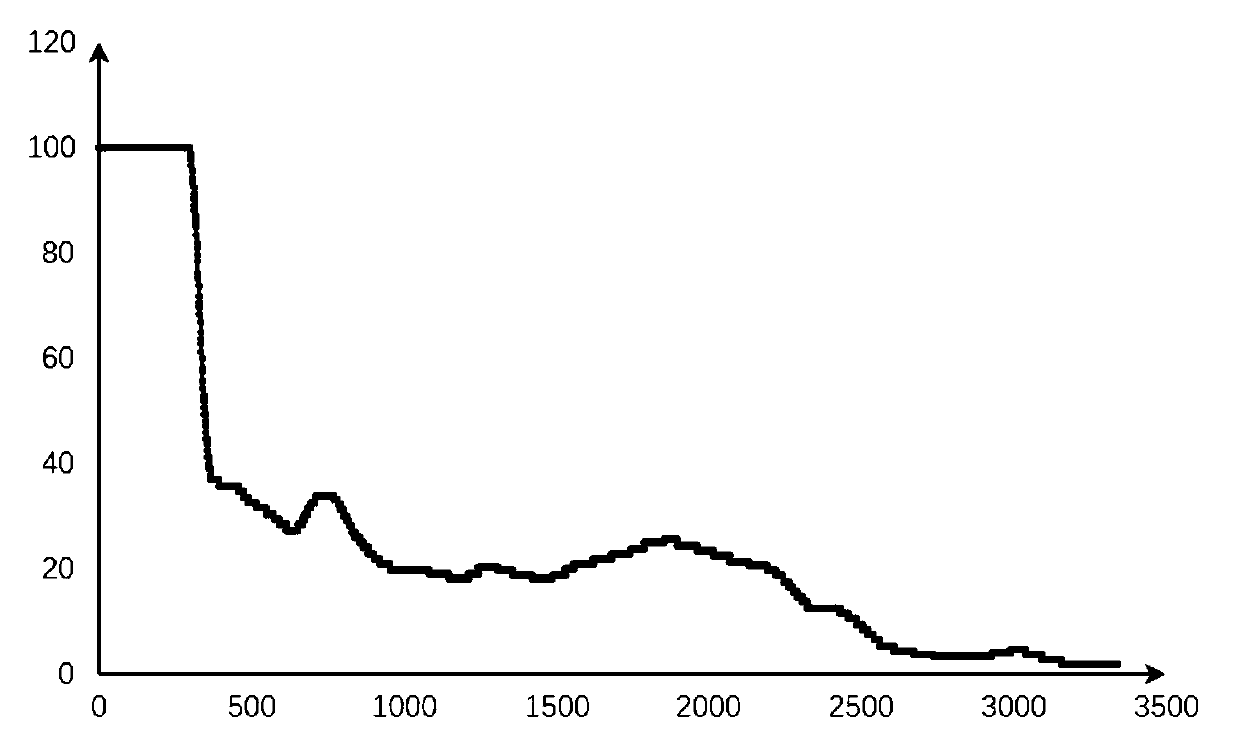

[0022] 1. Collect the historical operation data of the steam turbine in the recent period. Since it is necessary to select the operation data within the full opening range of the target regulating valve, the operation data of the steam turbine unit sequence valve steam distribution mode was collected for a period of time. The opening sequence of the sequence valve is 1 / 2-3-4. The comprehensive valve position command of the internal unit is reduced from 100% to 72%, and the opening of the high-press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com