Stator and motor with same

A stator and fixing hole technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of unguaranteed stator performance, poor voltage resistance between stator turns, unfavorable automatic production, etc., to improve the ability to adapt to automatic production, Reduce process defects and realize the effect of automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

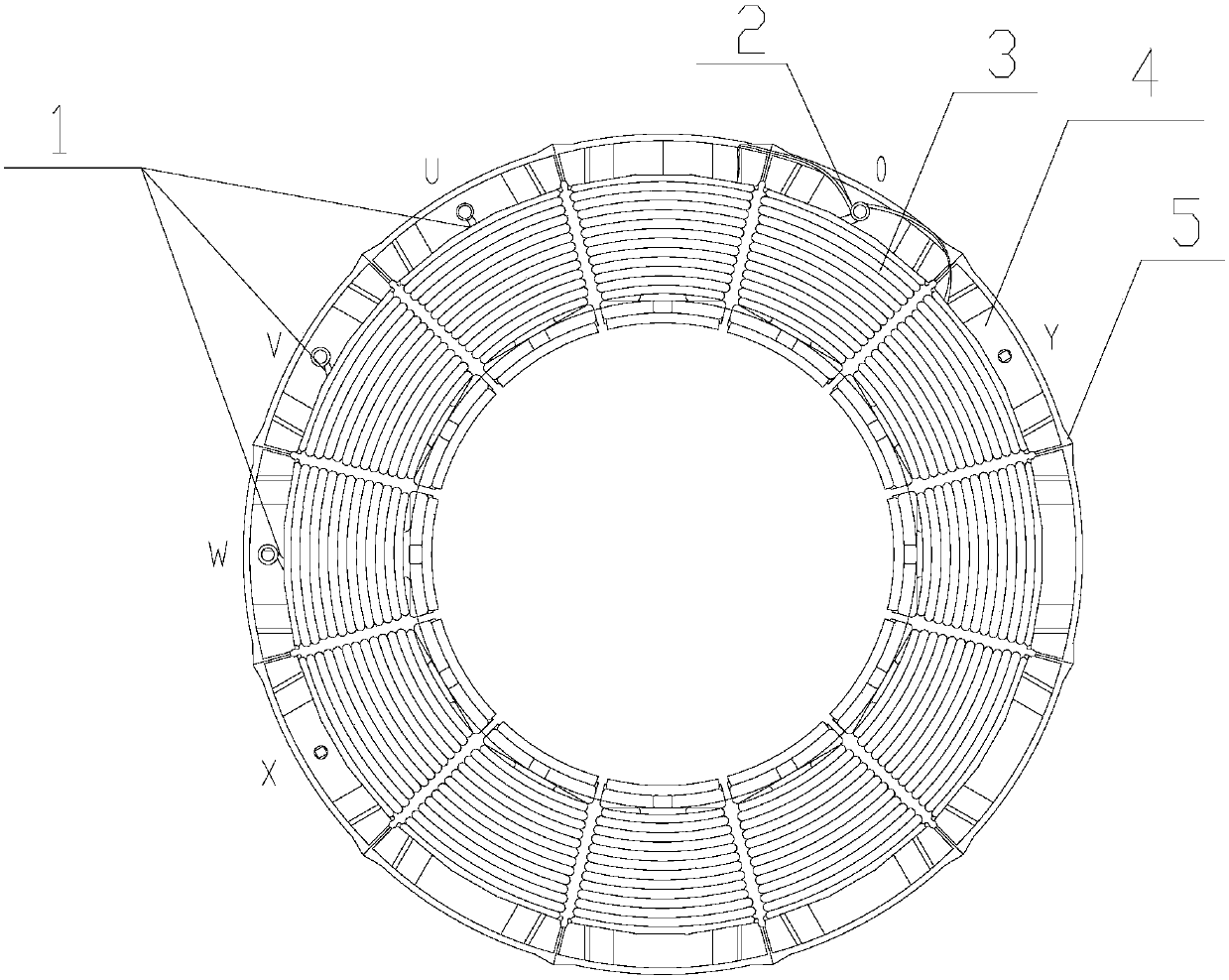

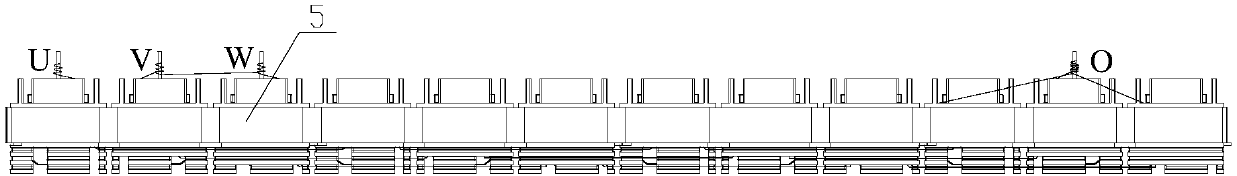

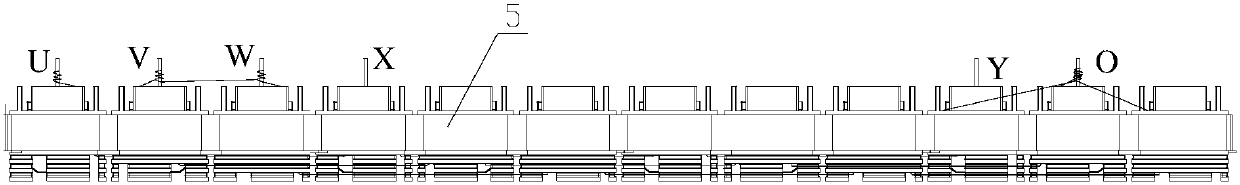

[0030] like Figure 4 to Figure 8 As shown, according to the embodiment of the present invention, the stator includes a stator body and an end protector 20 fixedly connected to one end of the stator body and covering the windings 11 of the stator body. By arranging the end protector 20 at the end of the stator body, the end of the winding 11 of the stator body can be closed, so as to protect the end of the stator winding 11 during welding, prevent tin dross from falling into the winding 11, and ensure the quality of the stator. Improve the ability to adapt to automated production. The stator solves the hidden danger of electrical safety caused by "fried tin" and foreign objects falling into the winding 11 of the stator winding of the motor, reduces process defects, realizes automatic production, and improves production efficienc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com