Electric appliance equipment water-cooling radiator

A technology for water-cooled heat dissipation and electrical equipment, which is applied to structural parts of electrical equipment, cooling/ventilation/heating renovation, electrical components, etc. Easy to operate and save interior space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order for those skilled in the art to better understand the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and the following embodiments.

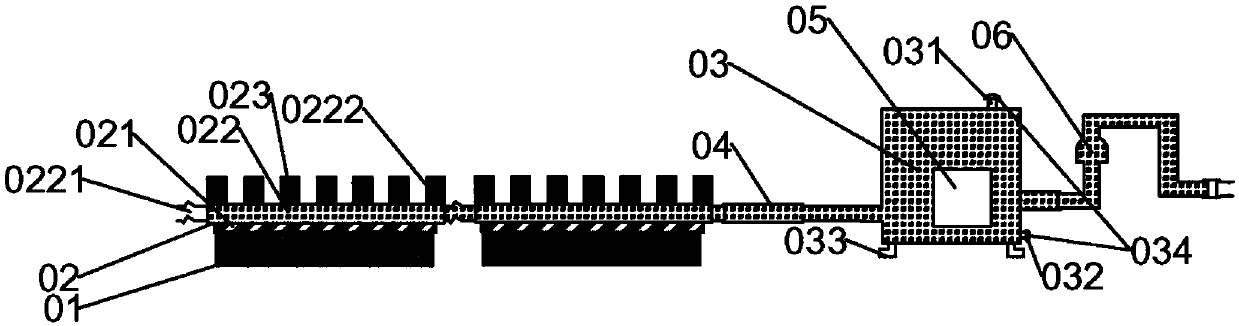

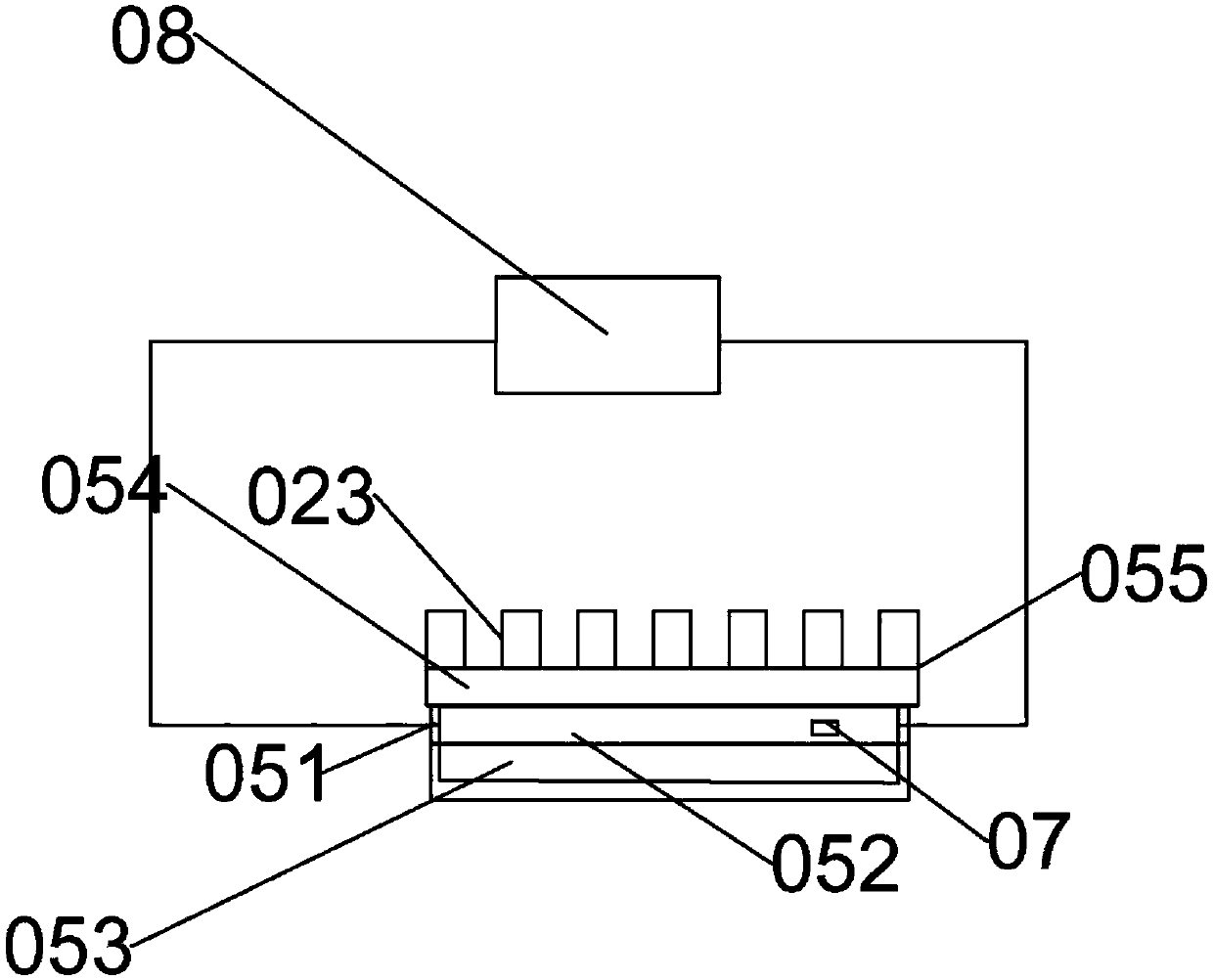

[0023] Please refer to figure 1 with figure 2 , the present embodiment provides a water cooling device for electrical equipment, including several cooling devices 02, a water tank 03, a semiconductor refrigeration module, a circulating pump 06 and a motor, and the cooling device 02 includes a cooling base, a cooling cavity 021 and several The protruding heat dissipation sheet 023, the heat dissipation base is fixedly connected with the heating element 01, the heat dissipation cavity 021 is hollow, and also includes a water inlet pipe 0221 and a water outlet pipe, the inside of which can be used for cooling liquid to flow, and the heat dissipation sheet 023 and the heat dissipation cavity 021 are integrally located on the other surface of the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com