Ultrasonic device, ultrasonic module, and ultrasonic measuring device

A technology of ultrasound and devices, applied in ultrasonic/sonic/infrasonic diagnosis, ultrasonic/sonic/infrasonic equipment control, material analysis using sound/ultrasonic/infrasonic, etc. It can solve problems such as reduced efficiency of ultrasonic transmission and reception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Hereinafter, the ultrasonic measurement device according to the present embodiment will be described based on the drawings.

[0056] [Configuration of Ultrasonic Measuring Device]

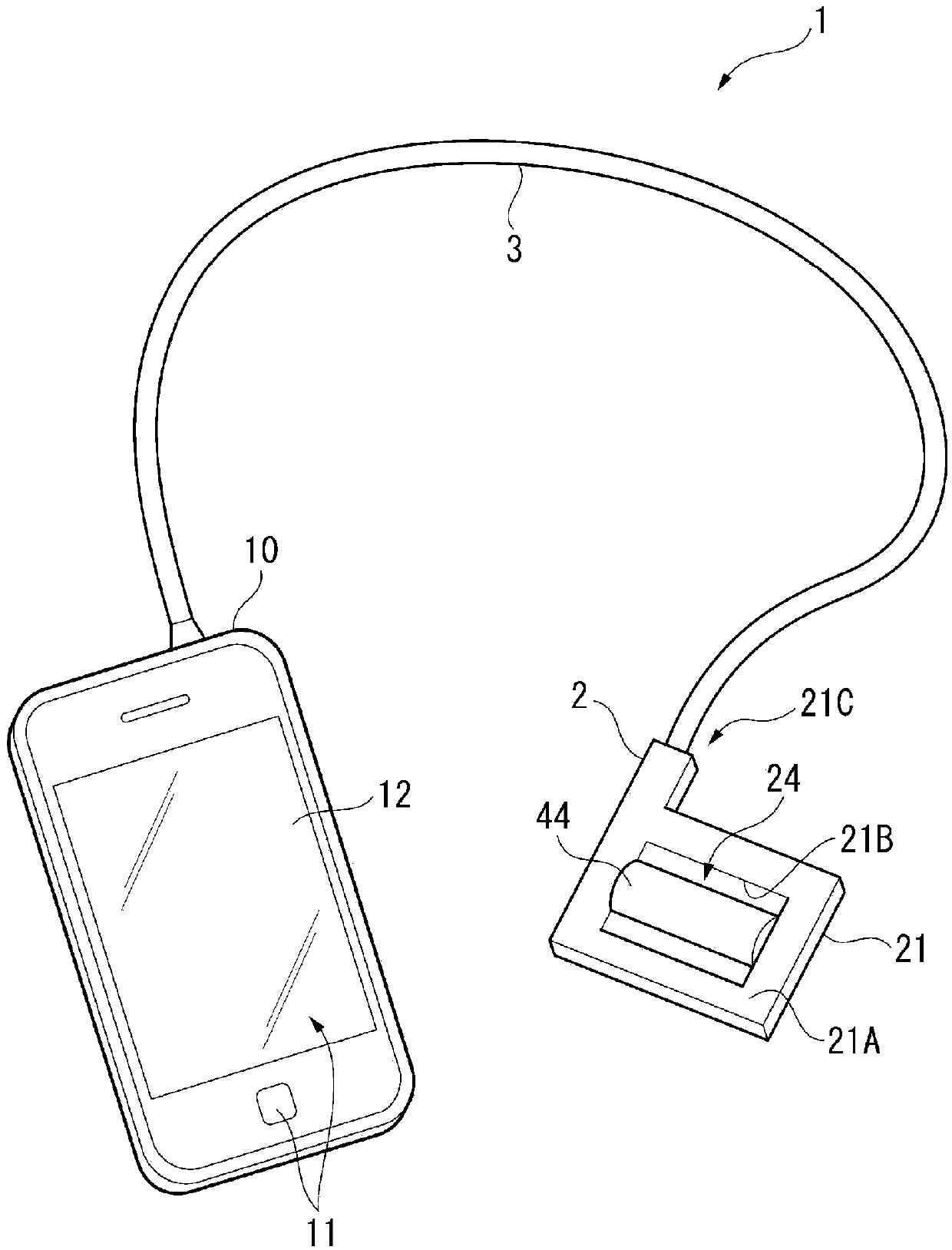

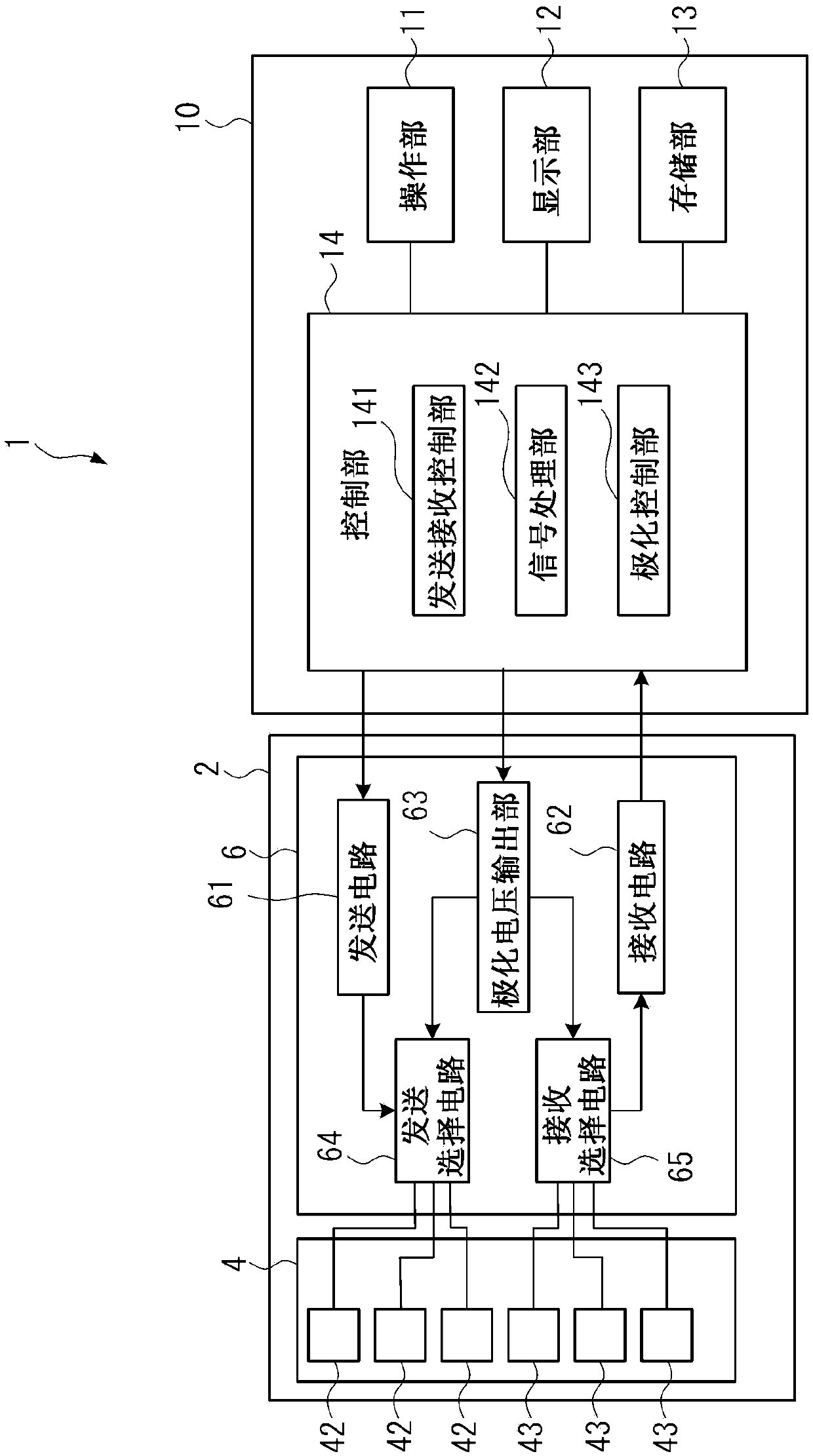

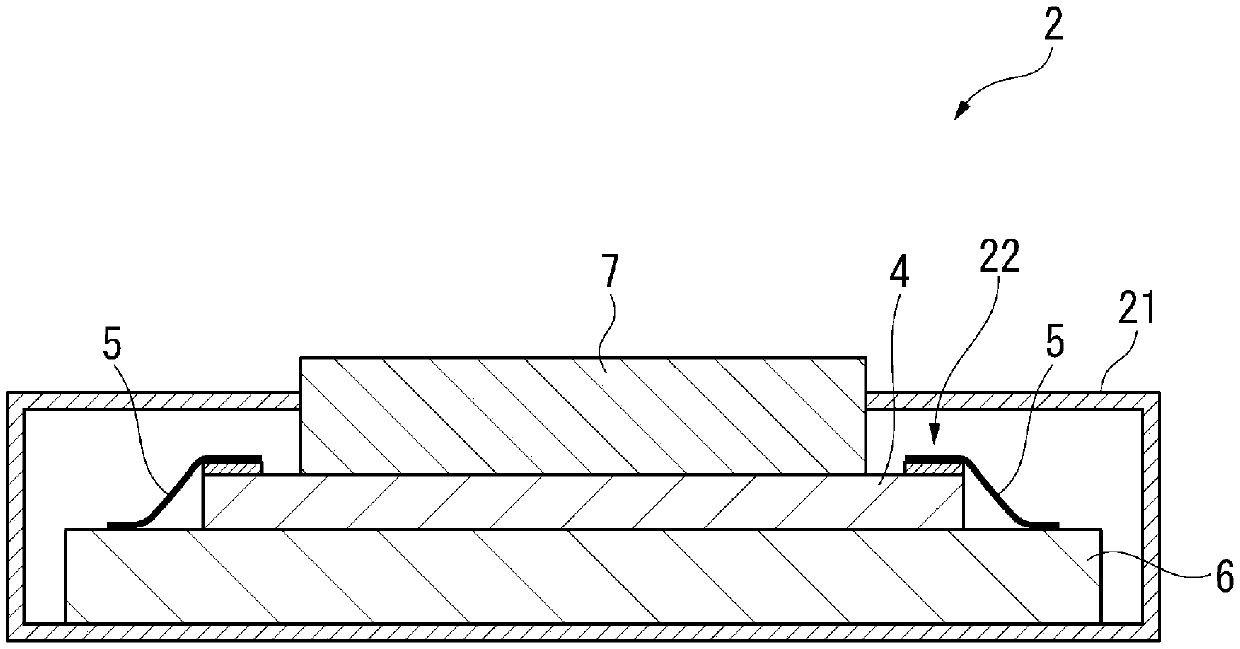

[0057] figure 1 It is a perspective view showing a schematic configuration of the ultrasonic measurement device 1 according to the present embodiment. figure 2 It is a block diagram showing a schematic configuration of the ultrasonic measurement device 1 according to the present embodiment.

[0058] Such as figure 1 As shown, the ultrasonic measurement device 1 of the present embodiment includes an ultrasonic probe 2 and a control device 10 electrically connected to the ultrasonic probe 2 via a cable 3 .

[0059] This ultrasonic measurement device 1 brings an ultrasonic probe 2 into contact with the surface of an object (for example, a living body), and sends ultrasonic waves from the ultrasonic probe 2 into the living body. Ultrasonic waves reflected by organs in the object (living bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com