Antenna packaging structure with air chamber and packaging method

An encapsulation method and encapsulation structure technology, which can be applied to antenna supports/installation devices, antennas, antenna parts, etc., can solve the problems of large loss of antenna encapsulation structure, and achieve the advantages of reducing package size, improving stability and reducing loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

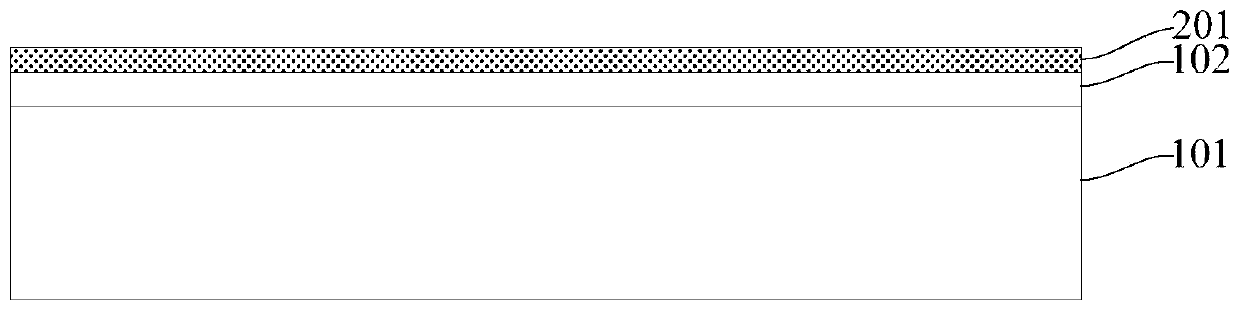

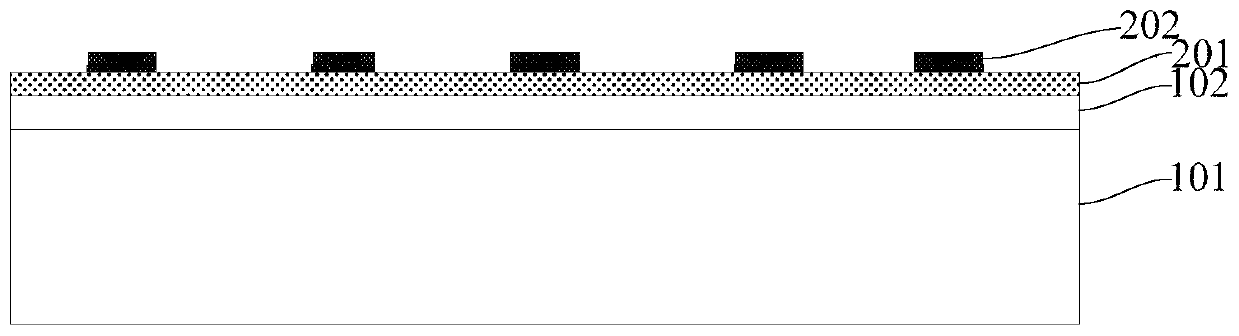

[0051] like Figure 1 to Figure 14 As shown, the present embodiment provides an antenna packaging method with an air cavity, and the packaging method includes the following steps:

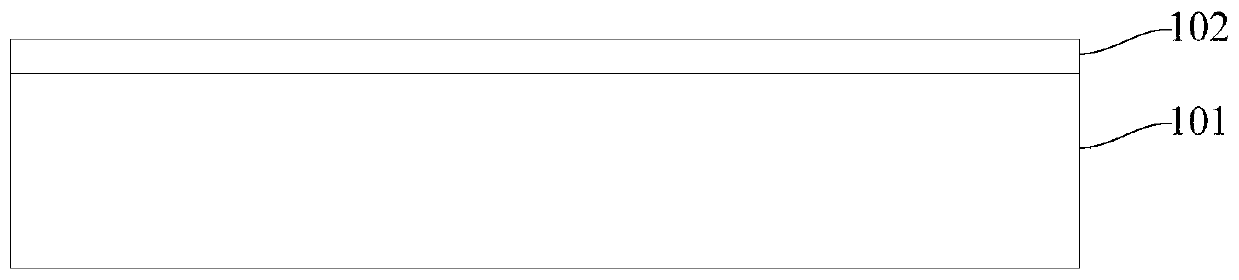

[0052] like figure 1 As shown, step 1) is firstly performed to provide a support base 101 on which the separation layer 102 is formed.

[0053] As an example, the supporting base 101 includes one of a glass substrate, a metal substrate, a semiconductor substrate, a polymer substrate and a ceramic substrate. In this embodiment, the support base 101 is selected as a glass substrate, the cost of the glass substrate is low, the separation layer 102 is easy to be formed on the surface of the glass substrate, and the difficulty of the subsequent peeling process can be reduced.

[0054] As an example, the separation layer 102 includes a light-to-heat conversion layer (LTHC), which is formed on the support substrate 101 by a spin-coating process, and then cured and shaped by a curing process. The perfor...

Embodiment 2

[0086] like Figure 15 As shown, this embodiment provides an antenna packaging structure and packaging method with an air cavity, and its basic steps and structure are as in Embodiment 1, wherein the difference from Embodiment 1 lies in that the first part of the substrate 601 Both sides are bonded to the chamber side wall 205 so that the antenna metal layer 603 is located outside the air chamber. The packaging structure and method can make the antenna metal layer 603 exposed on the top of the antenna packaging structure, which can facilitate the electrical connection between it and other components, and can enhance the efficiency of sending and receiving signals of the antenna metal layer 603 .

[0087] As mentioned above, the antenna packaging structure and packaging method with an air cavity of the present invention have the following beneficial effects:

[0088] The present invention can integrate all active components or passive components in one packaging structure thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com