Progressive increasing type rolling method

An incremental, rolling technology, applied in the direction of metal processing equipment, etc., can solve the problem that the deformation point is prone to breakage

Inactive Publication Date: 2018-03-09

YANGZHOU RUICHENG STEEL IND

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This rolling method is always at a deformation point during deformation rolling. During continuous rolling, stretching and thinning occur at the deformation point, and the deformation point is prone to breakage during use.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

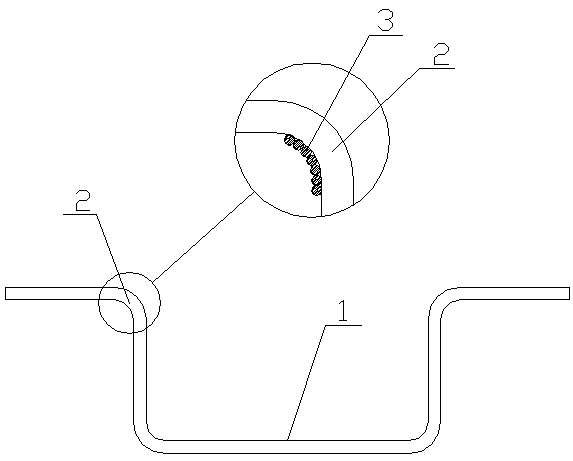

[0008] Such as figure 1 As shown, the outer edge channel steel 1 of the workpiece is rolled from 15°, 30°, 45°, 60°, 75°, 80°, 85°, 90° During the eight times of deformation, the roll marks are scattered on seven deformation points 3, and the seven deformation points 3 are distributed inside the bend 2 of the outer crimping channel steel 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The incremental rolling method relates to the technical field of a profile rolling method. At the bending position of the profile, during the eight deformation processes from 15°, 30°, 45°, 60°, 75°, 80°, 85°, and 90°, the roll marks are scattered on seven deformation points, and the seven deformation points The deformation points are distributed on the inner side of the bending of the outer crimping channel steel. The internal stress generated by the rolling of this process is all on different points, and the internal stress during product rolling has been released. The two sides of the workpiece are 90 degrees, and the two small sides are flat. There is no deep mark or stretch on the R point of the product. The thickness of the plate does not change and the strength is guaranteed. The surface of the product is smooth and clean, and the customer praise is high.

Description

technical field [0001] The invention relates to the technical field of a profile rolling method. Background technique [0002] For a rolled product of channel steel with external crimping, after it is produced, two small sides are often uneven, always collapsed, not at 90°, the roll line is relatively deep, and the R part is stretched. When other profiles are tailor-welded, there are gaps that cause virtual welding, and the virtual welding points are prone to water ingress and rust. directly affect the durability of the product. [0003] Aiming at the quality problem of this product, we have analyzed and researched the process design of the product. The traditional design of the old process is that the length of each side is fixed, and gradually becomes 90° with the angle deformation. This rolling method is always at a deformation point during deformation rolling. During continuous rolling, stretching and thinning occur at the deformation point, and the deformation point i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21D5/14B21D47/00

CPCB21D5/14B21D47/00

Inventor 丁凤友房发成叶君

Owner YANGZHOU RUICHENG STEEL IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com