Spot-welding and arc-welding integrated station and control method thereof

An arc-spotting and controller technology, applied in manufacturing tools, arc welding equipment, welding equipment, etc., can solve the problems of large workshop area, reduced production efficiency, occupation, etc., to reduce floor space, save costs, reduce effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

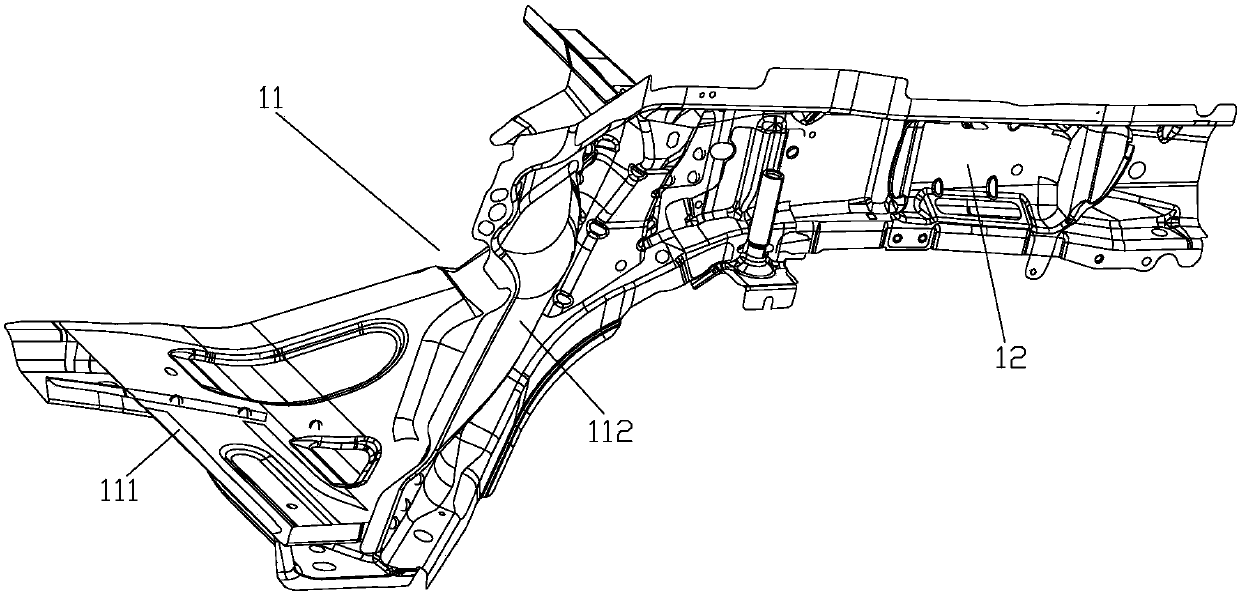

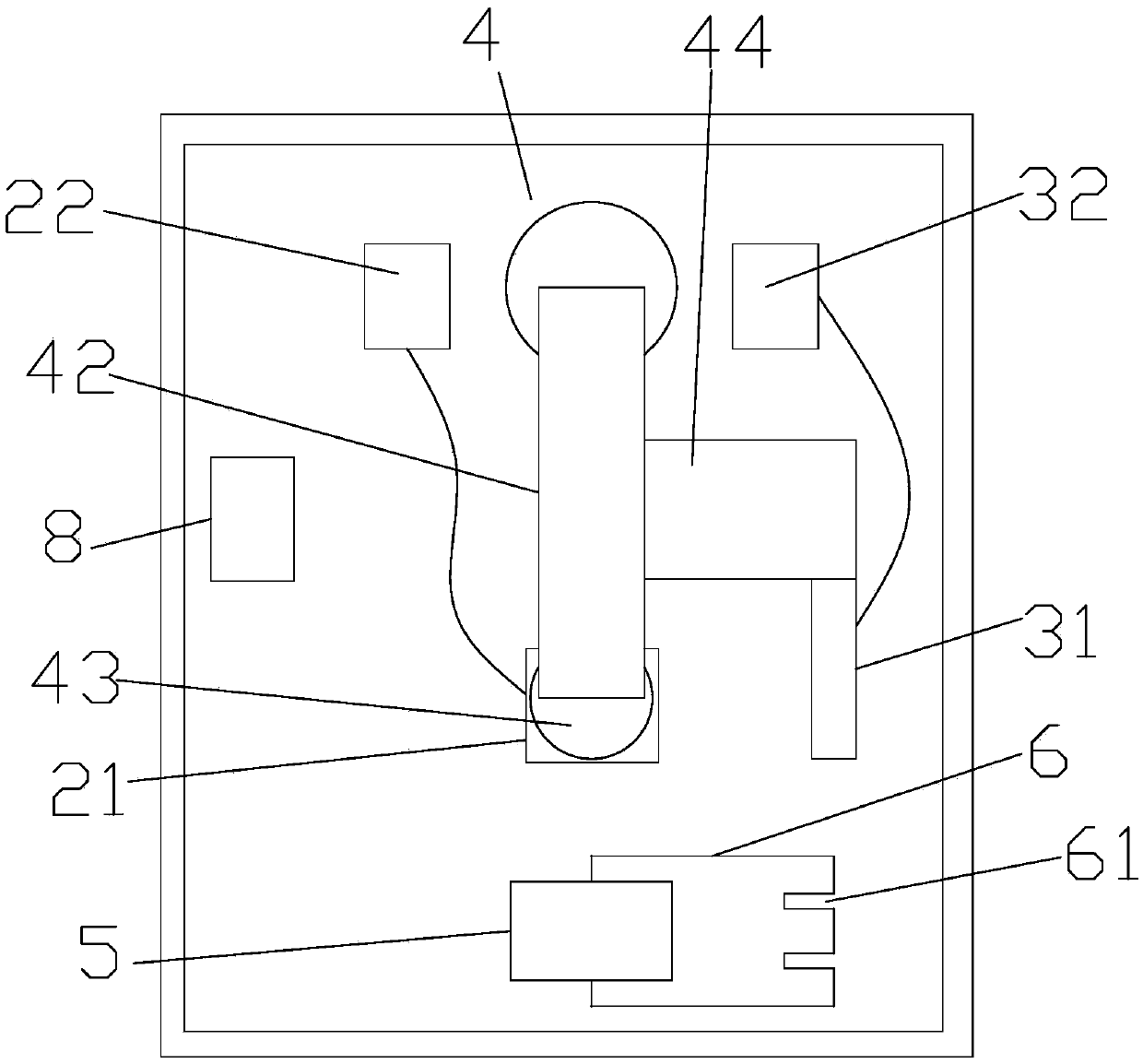

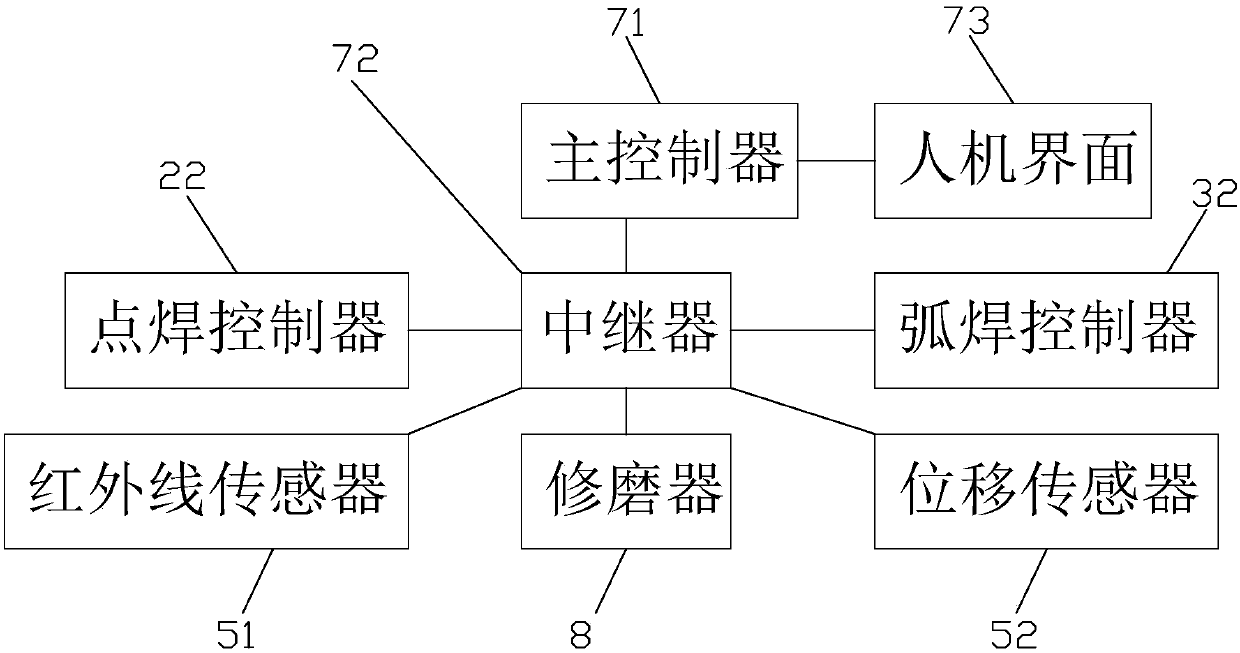

[0040] Such as figure 2 as well as image 3 As shown, the present invention proposes a kind of point arc integrated station, comprising:

[0041] A spot welding device, the spot welding device includes a spot welding gun 21, and the spot welding gun 21 is electrically connected to a spot welding controller 22 through a spot welding relay;

[0042] An arc welding device, the arc welding device includes an arc welding torch 31, and the arc welding torch 31 is electrically connected to an arc welding controller 32 through an arc welding relay;

[0043] The robot 4, the robot 4 includes a welding manipulator and a robot controller 41, the welding manipulator is provided with a welding arm 42, the tip of the welding arm 42 is provided with a mounting plate 43 for installing the spot welding torch 21, and one side of the welding arm 42 is provided with There is a mounting plate 44 for installing the arc welding torch 31, the distance between the spot welding torch 21 installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com