Concrete pole outer surface mark forming method

A molding method and outer surface technology, applied in the direction of ceramic molding machines, molds, manufacturing tools, etc., can solve the problems of high production cost and increase the production burden of enterprises, and achieve the effect of low production cost, short processing cycle and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

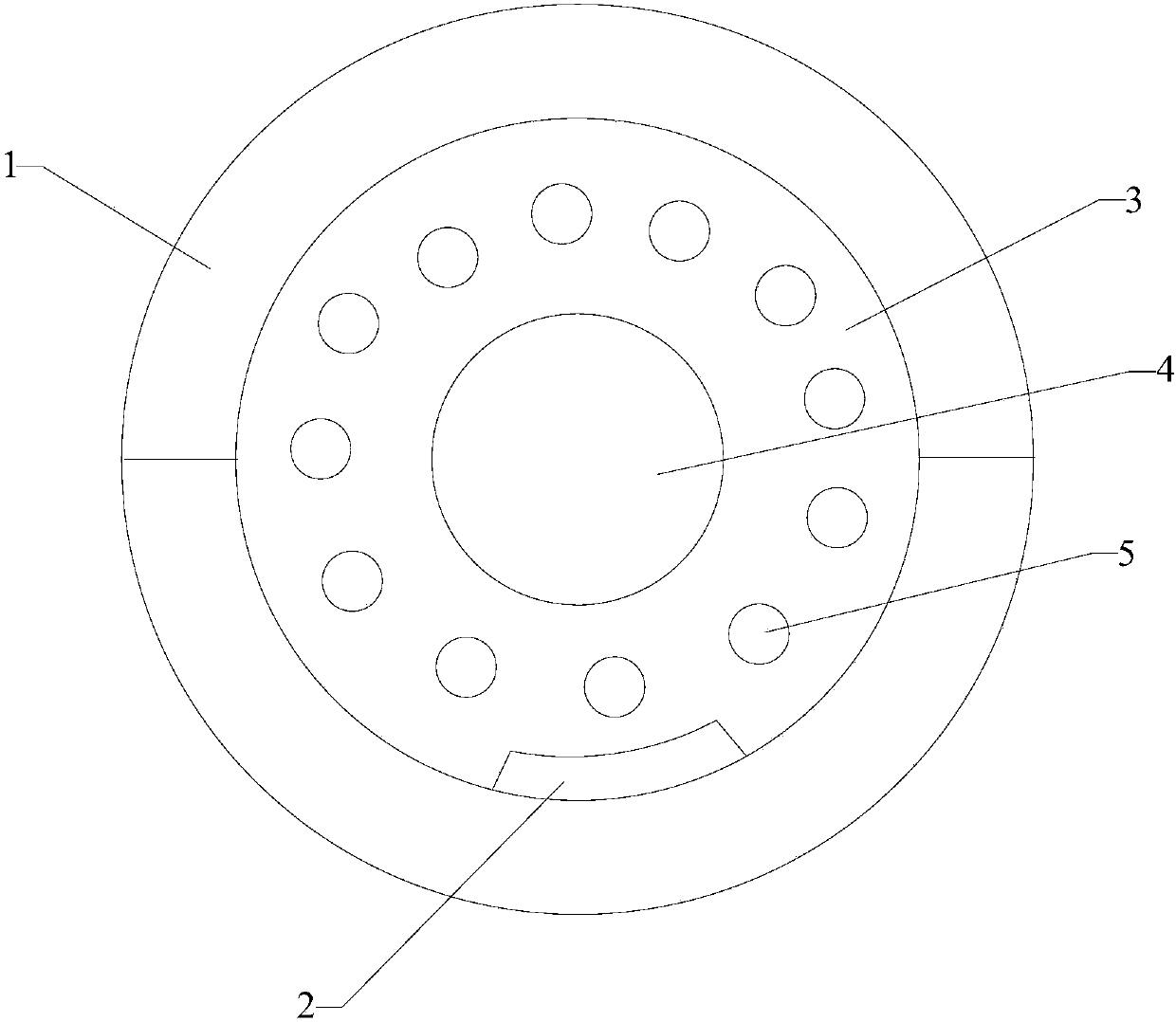

[0028] Please refer to figure 1 Shown, embodiment one of the present invention is:

[0029] A marking forming method on the outer surface of a cement pole, which comprises making a mold piece 2 with the same shape as the marking; attaching the mold piece 2 to the inner wall of a mold 1, the mold 1 includes an inner mold 4, and the inner mold 4 is arranged on the mold 1. Cavity; install steel bar 5 in mold 1, and evenly position steel bar 5 along the circumference, close mold 1, pour cement in mold 1, open the mold after the cement hardens, and take out cement rod 3.

[0030] To sum up, the method for forming markings on the outer surface of cement rods provided by the present invention only needs to make molds with uniform specifications, and attach the markings to be processed on the inner wall of the mold in the form of dies, and then process the markings with grooves. The production cost is low, the versatility is good, the processing cycle is short, and the industrial com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com