Rail traffic van support structure

A technology for supporting structures and rail transit, which is applied to trucks, cargo supporting/secured components, and transport passenger cars. The effect of automating operations, improving ride safety, and reducing freight and passenger costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

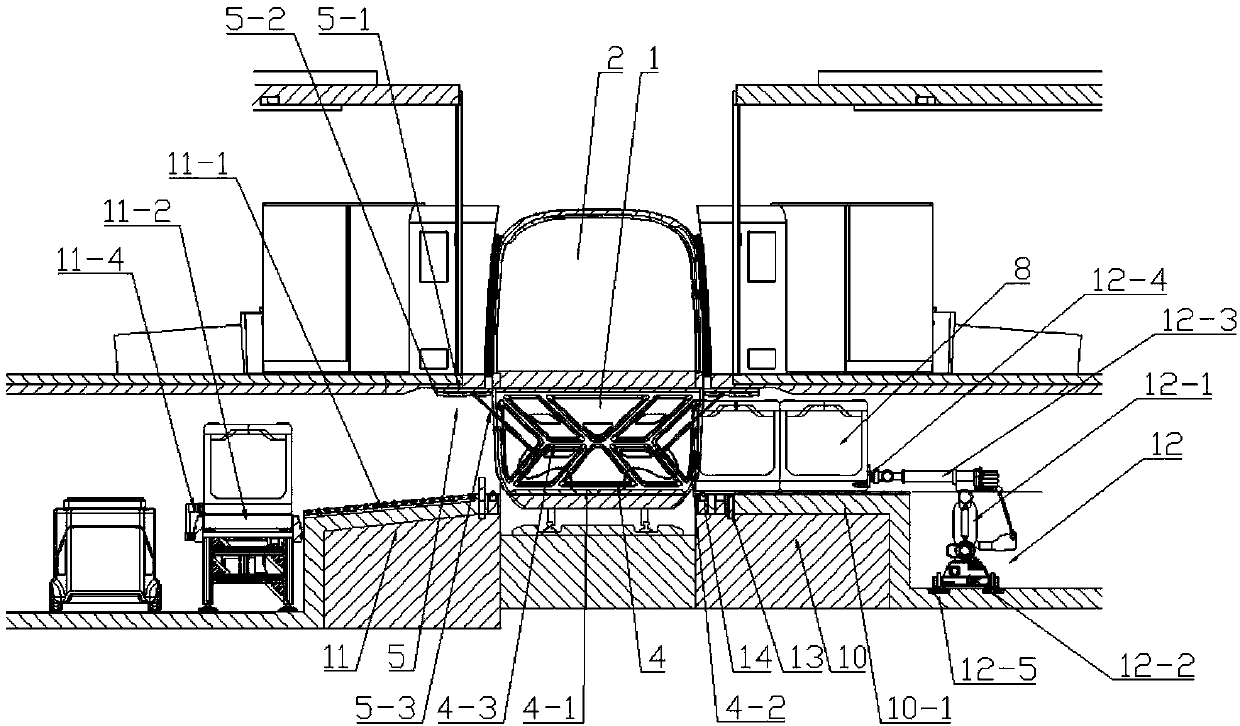

[0031] The supporting structure of a rail transit freight car according to the present invention is mainly applied to a rail transit freight car, and the freight car is a double-decker train.

[0032] Such as Figure 1 to Figure 3 As shown, the rail transit truck includes a first layer at the bottom and a second layer above the first layer, that is, the truck adopts a double-layer structure. The first layer at the bottom is used for freight, and the second layer can be used for freight or passenger transportation. In this embodiment, the second layer is the passenger compartment 2 .

[0033] The first floor has a cargo hold space that passes through from one head car to the other head car, and a support structure 4 is arranged in the cargo hold space, and the support structure 4 is used to carry the passenger cabin 2 .

[0034] The cargo compartment space is divided into multiple independent spaces by the supporting structure 4, one part of which is the equipment compartment ...

Embodiment 2

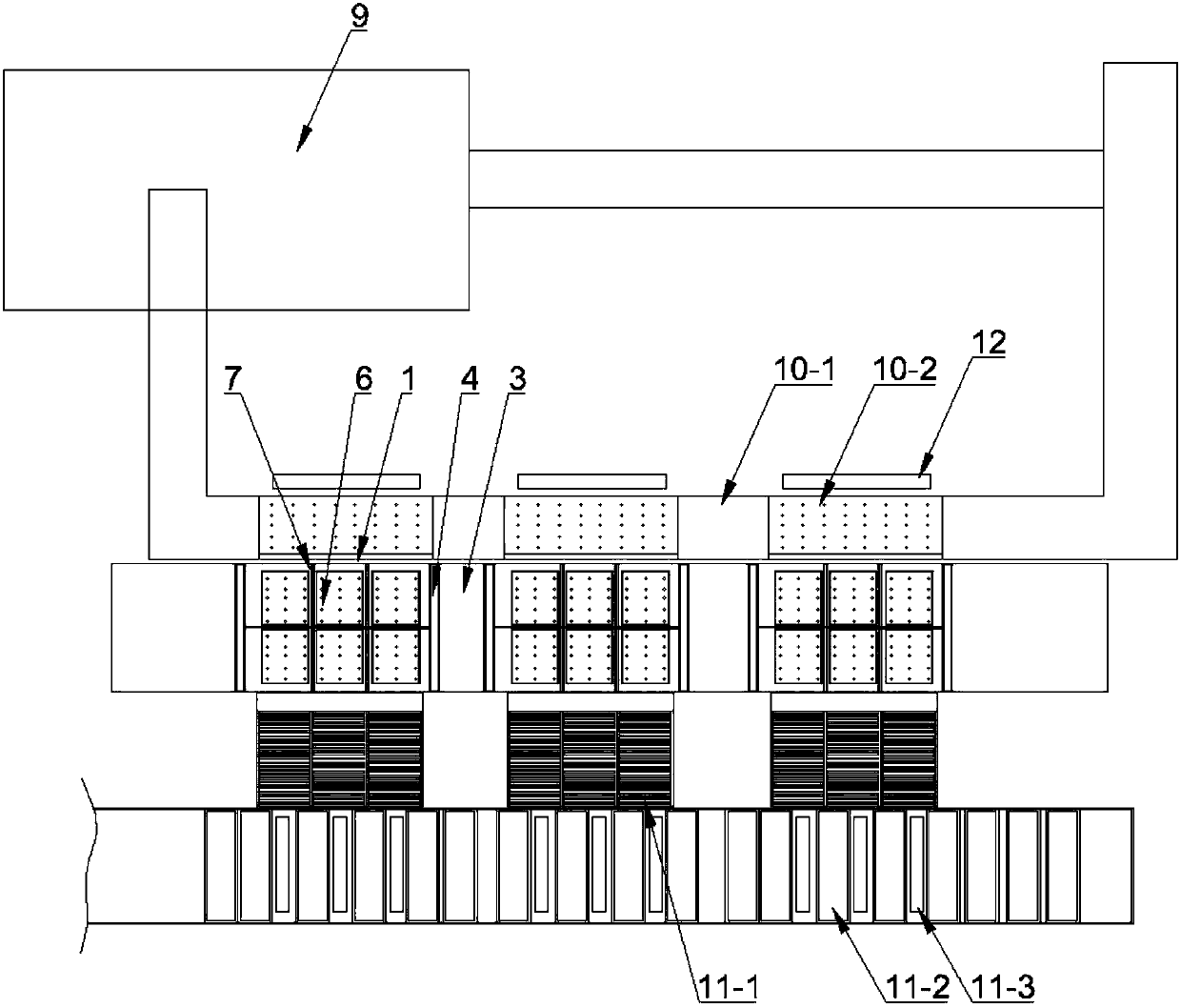

[0039] Such as figure 1 , 2 As shown, in this embodiment, a cargo floor is set in the cargo hold 1, and the cargo floor is divided into a plurality of cuboid blocks, and each cargo floor is provided with a plurality of balls 6, and the balls 6 are used for cargo or containers to be placed in the cargo hold 1. internal displacement.

[0040] A lifting and positioning structure 7 is provided in the cargo compartment 1, and the lifting and positioning structure 7 is used for fixing and positioning goods or containers. Lifting and positioning structure 7 is arranged between two adjacent cuboid block cargo hold floors, and the section shape of lifting and positioning structure 7 is "convex" shape, and lifting and positioning structure 7 cooperates with the bottom of freight container 8. After the container 8 is loaded in place, the lifting positioning structure 7 rises and fixes the container 8 to prevent it from shaking during the operation of the truck and damage the car body s...

Embodiment 3

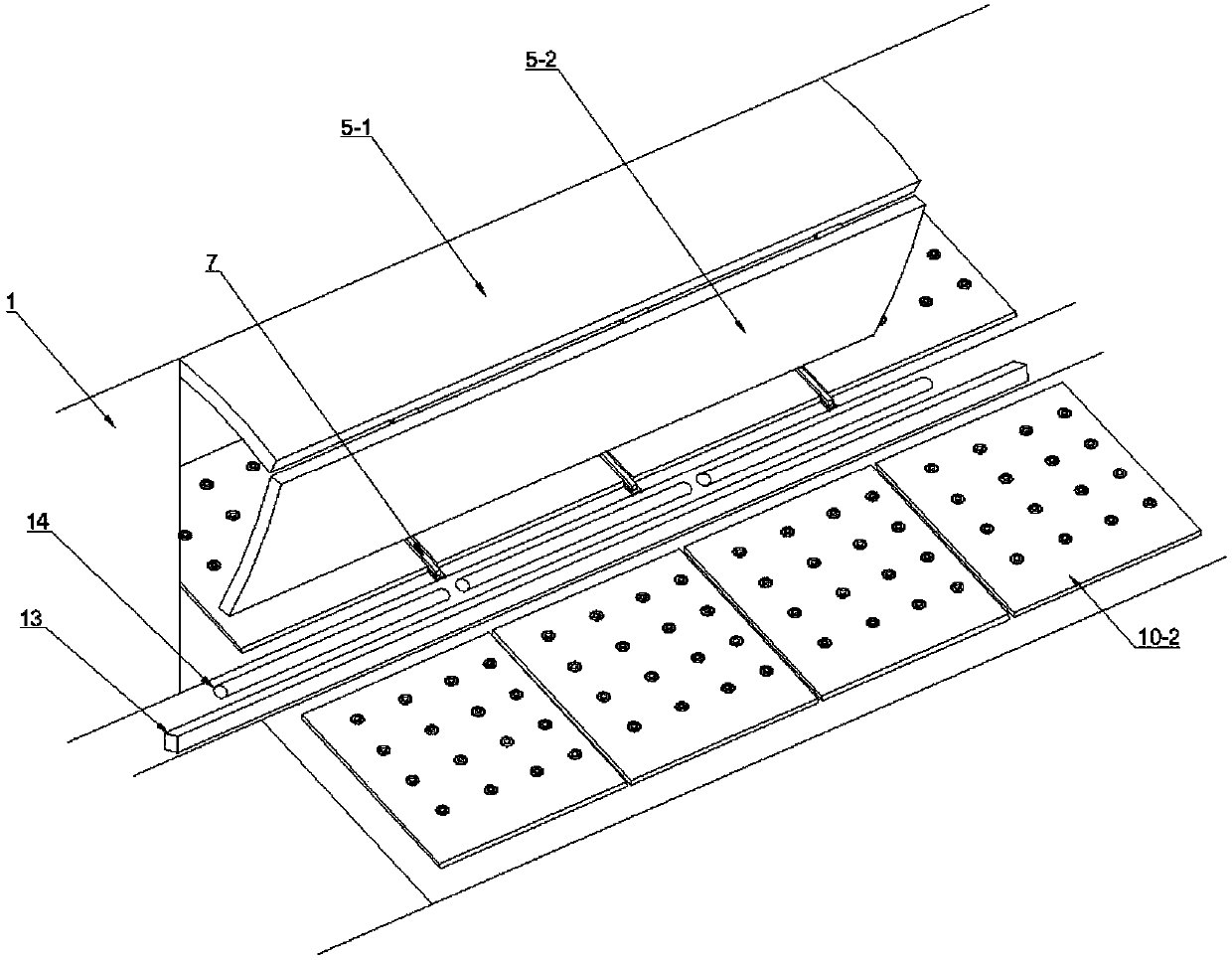

[0075] In this embodiment, the cargo door is a folding door 5, and the folding door 5 includes an upper page 5-1 and a lower page 5-2. When the folding door 5 is opened, the upper page 5-1 and the lower page 5-2 are folded and overlapped. Realize the opening of the door body.

[0076] The top of the previous page 5-1 is hinged to the car body frame, the bottom of the previous page 5-1 is hinged to the top of the next page 5-2, and a follower device is arranged between the previous page 5-1 and the next page 5-2. When the upper page 5-1 is overturned, the lower page 5-2 is overturned by the follower to realize the folding of the two.

[0077] In this embodiment, the follower device adopts multiple spring hinges or multiple hydraulic hinges.

[0078] Since the outside of the cargo hold door is the loading channel 10, in order to avoid the collision between the door body and the container 8, and also to reduce the distance between the container 8 and the cargo hold 1, the foldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com