Automotive wire winding device

A winding device and wire rod technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of irregular winding, unstable winding tension, insufficient flexibility, etc., and achieve convenience Transportation, avoiding sagging of the insulating rubber layer, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

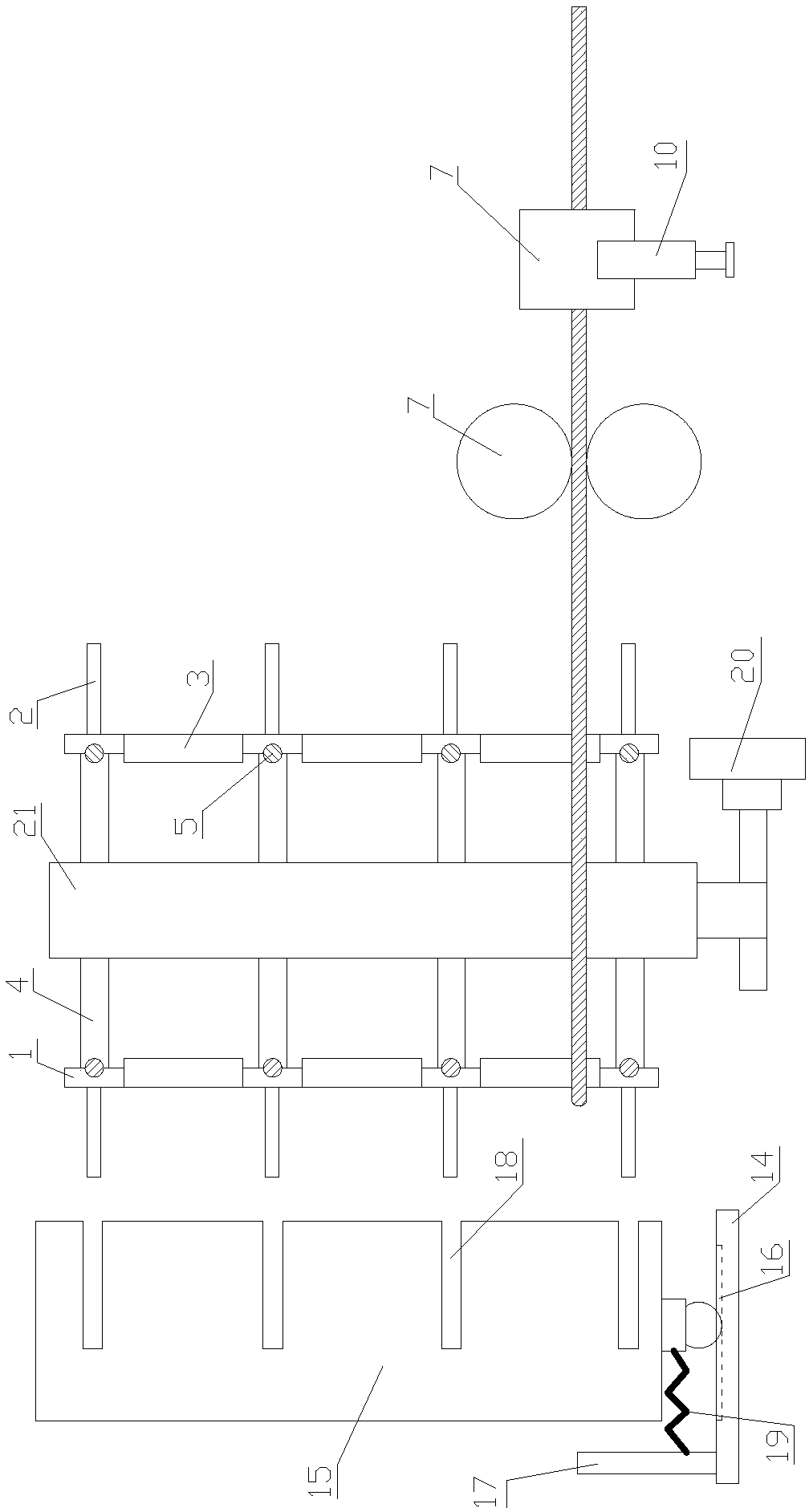

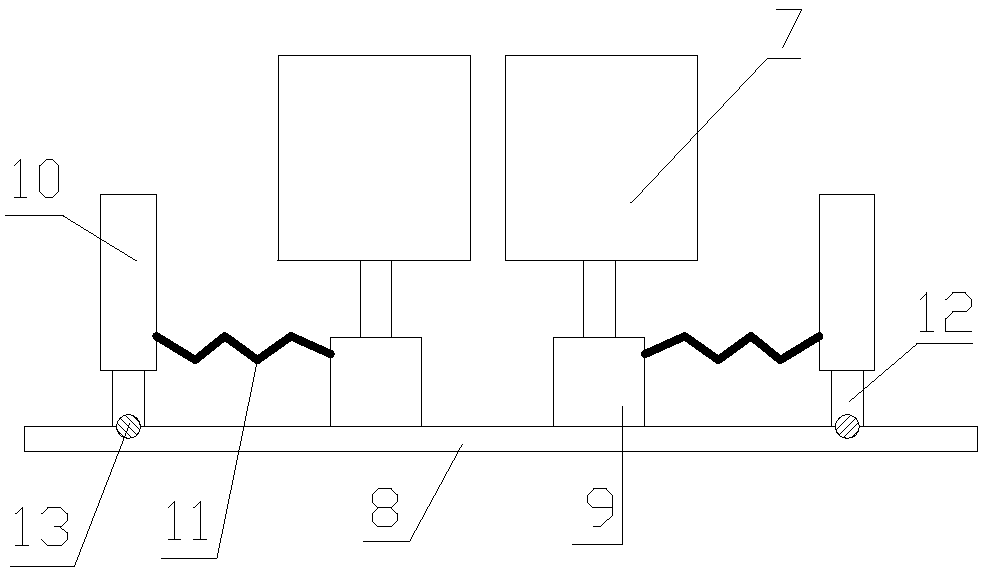

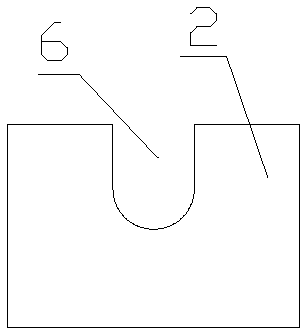

[0028] refer to figure 1 , 2 , 3: A kind of automobile wire rod rewinding device proposed by the present invention, comprises rotating shaft 21, and this rotating shaft is provided with N supporting mechanism along its circumference, N≥2, and this supporting mechanism comprises several supporting plates 1, and this supporting plate 1 is along rotating shaft 21 The axial interval distribution of the support plate 1 is provided with a wire retaining plate 2, and a connection plate 3 for winding cables is provided between adjacent support plates 1, and the two ends of the connection plate 3 are detachably connected with the support plate. A cable channel for allowing cables to pass is provided on the wire baffle plate 2 .

[0029] The cables are wound in the area formed by the wire retaining plate 2 and the connection plate 3, and the number of the connection plates 3 is flexibly selected according to the number of cables. When in use, the cables can be used in sequence. When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com