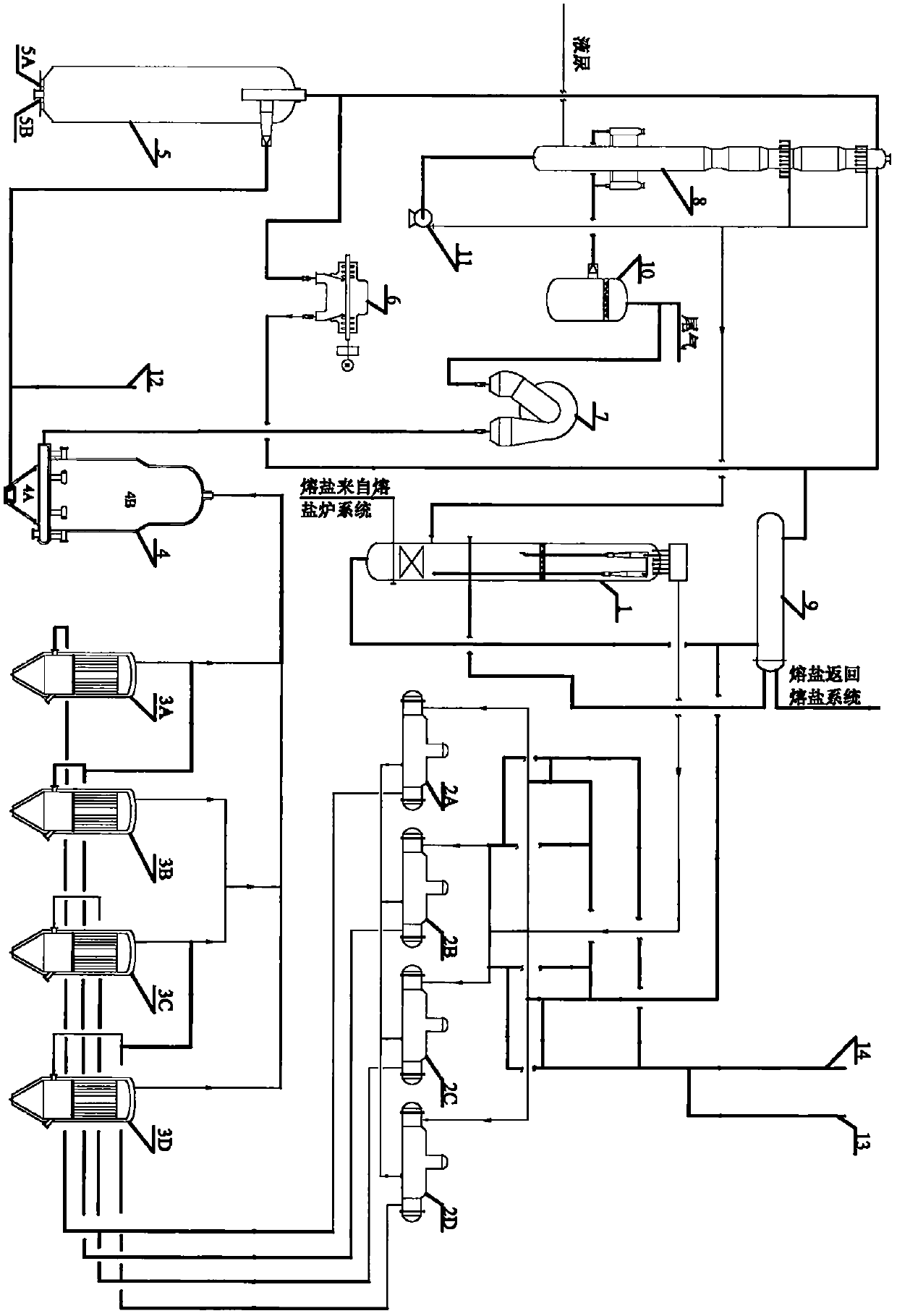

Energy-saving low-pressure cold-brew melamine production technology

A technology for extracting and cooling melamine and a production process, which is applied in the field of energy-saving low-pressure extraction and cooling melamine production technology, can solve the problems of low product quality, low rate of high-quality products, scarring of compressor impellers, and restrictions on popularization and application, so as to eliminate the problem of scarring, Remarkable energy saving effect and the effect of prolonging the operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A melamine plant of 50,000 tons / year has been built with the method of the present invention, and the investment is less than 215 million yuan; 2 years of operation and trial production, the average daily production of 180 tons of melamine; the rate of excellent product quality reaches 96.78%; ≤700 kWh; urea ≤3.0 tons; catalyst ≤1 kg; continuous operation period up to 180 days, with an average of 145 days; all emission indicators are within the allowable range of environmental protection indicators.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com