High-efficiency adhesive for hot vulcanized rubber shoes as well as preparation method and using method of adhesive

A technology of adhesive and thermal vulcanization, which is applied in the field of rubber processing and can solve problems such as not being able to meet customer product quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

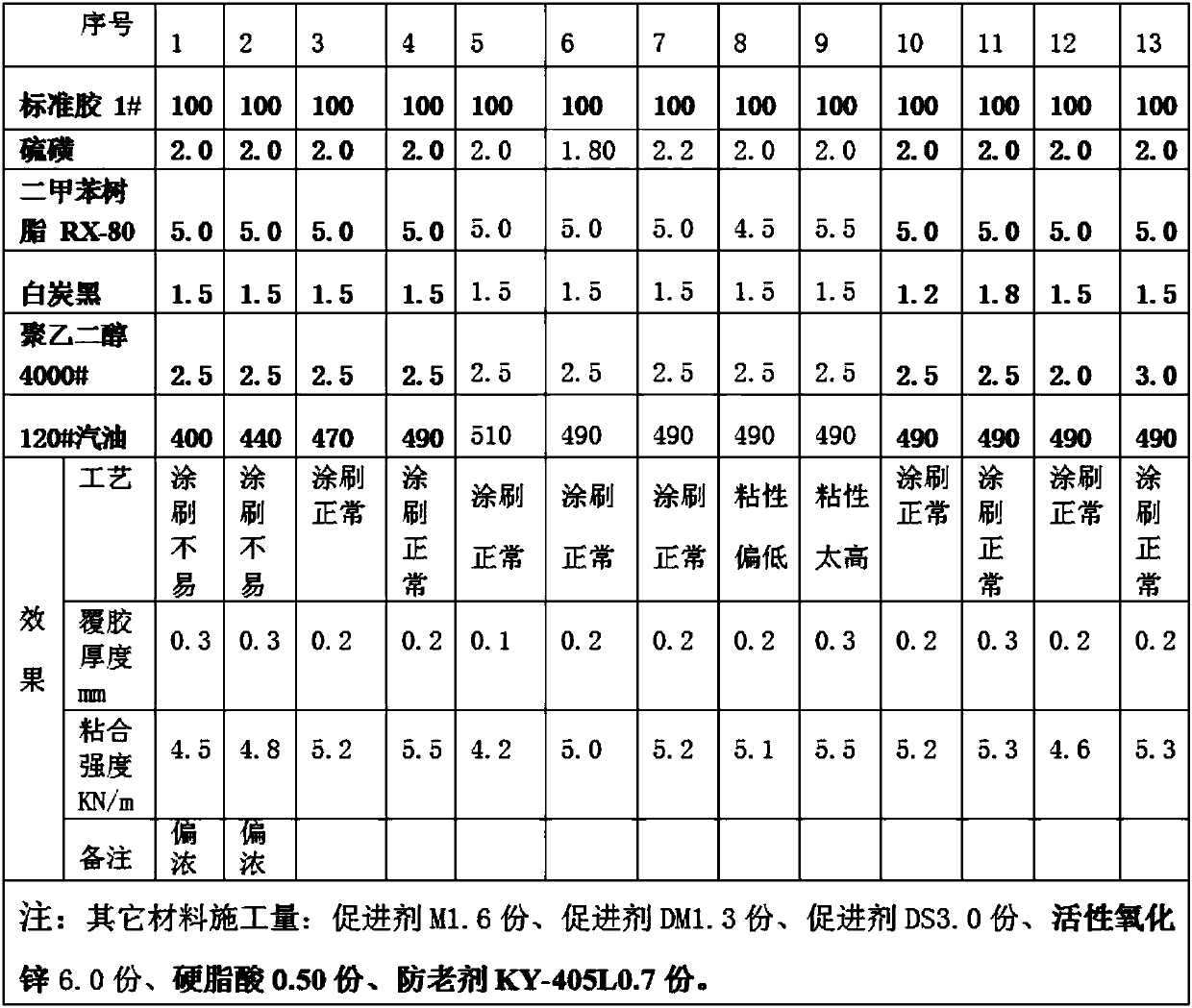

Embodiment 1

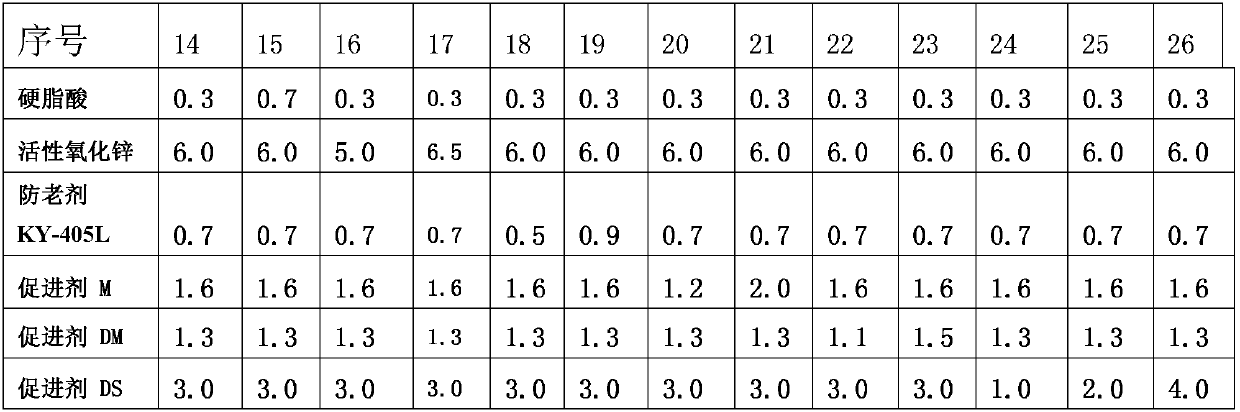

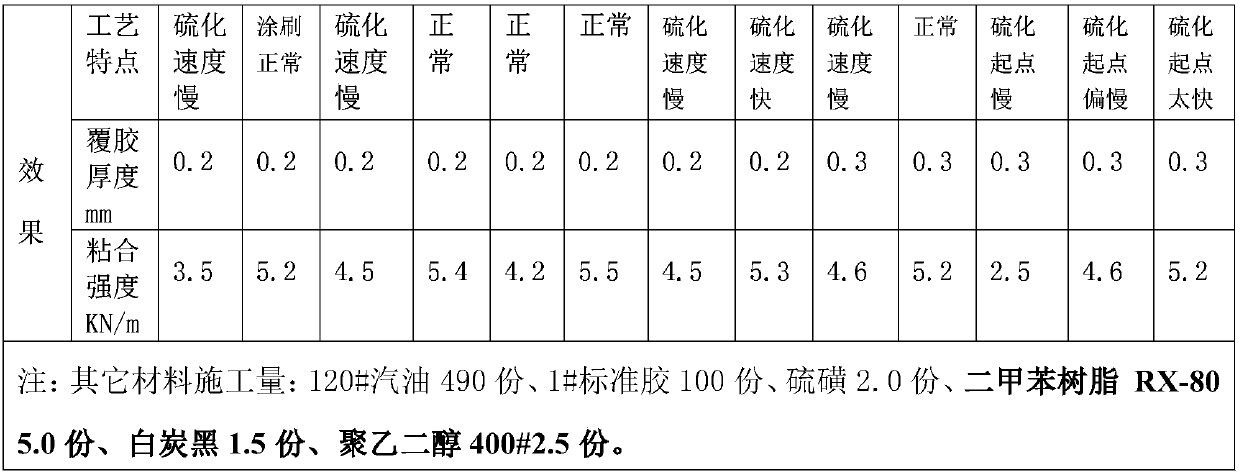

[0087] Embodiment 1 of the present invention: high-efficiency adhesive for hot-vulcanized rubber shoes, including a shoe upper surface treatment agent, an upper surface adhesive, and a shoe-wrap rubber bar surface treatment agent; calculated in parts by mass, the composition of the shoe upper surface treatment agent includes 5 Parts of curing agent E766, 95 parts of treatment agent Na036; the upper adhesive is adhesive Na047; the composition of the surface treatment agent for shoe circumference rubber bars includes 100 parts of natural rubber, 2 parts of sulfur, 6 parts of vulcanization accelerator, vulcanization activity 6.5 parts of agent, 1.5 parts of white carbon black, 2.5 parts of polyethylene glycol 4000#, 5 parts of tackifying resin, 0.7 parts of anti-aging agent KY-405L, 490 parts of 120# gasoline; every 6 parts of accelerator consists of accelerator M1.7 1.3 parts of accelerator DM and 3 parts of accelerator DS. The tackifying resin is xylene resin RX-80; every 6.5 p...

Embodiment 2

[0108] Embodiment 2 of the present invention: high-efficiency adhesive for hot-vulcanized rubber shoes, including a shoe upper surface treatment agent, an upper surface adhesive, and a shoe-wrap rubber bar surface treatment agent; calculated in parts by mass, the composition of the shoe upper surface treatment agent includes 5 Parts of curing agent E766, 95 parts of treatment agent Na036; the upper adhesive is adhesive Na047; the composition of the surface treatment agent for the shoe circumference rubber bar includes 100 parts of natural rubber, 2.1 parts of sulfur, 6 parts of vulcanization accelerator, vulcanization activity 6.3 parts of white carbon black, 1.2 parts of white carbon black, 2.5 parts of polyethylene glycol 4000#, 4.6 parts of tackifying resin, 0.7 parts of anti-aging agent KY-405L, 495 parts of 120# gasoline; every 6 parts of accelerator consists of accelerator M1.7 1.3 parts of accelerator DM and 3 parts of accelerator DS. The tackifying resin is xylene resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com