Anti-static dust-collecting water-blocking cloth rubber shoe adhesive, and preparation method and use method thereof

An adhesive and anti-static technology, applied in the field of rubber processing, can solve problems such as low adhesive strength, inability to meet special functional requirements, and inability to achieve aesthetic requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

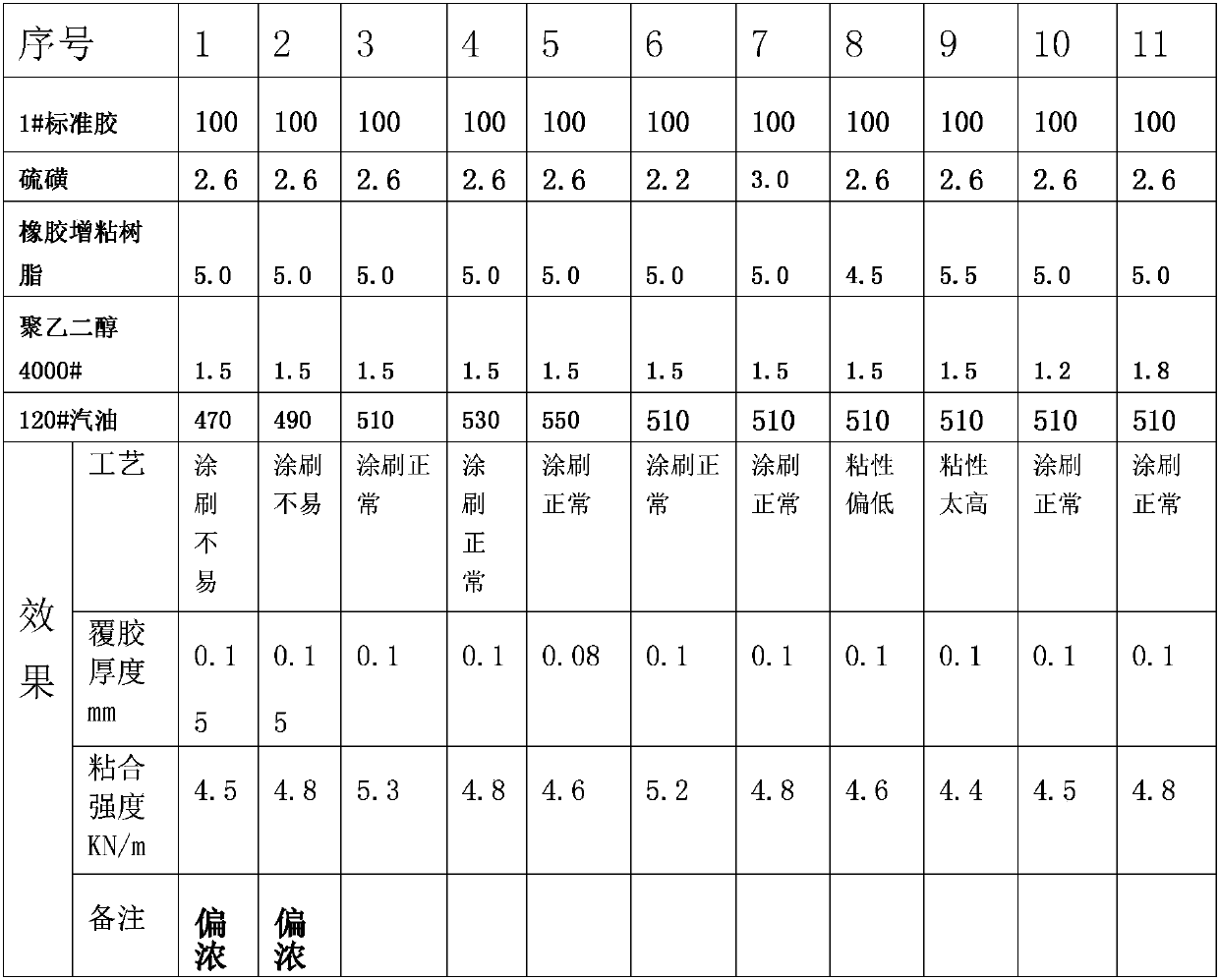

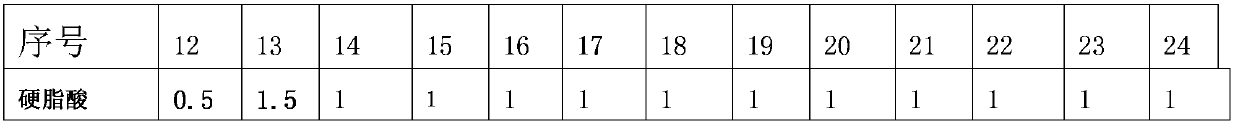

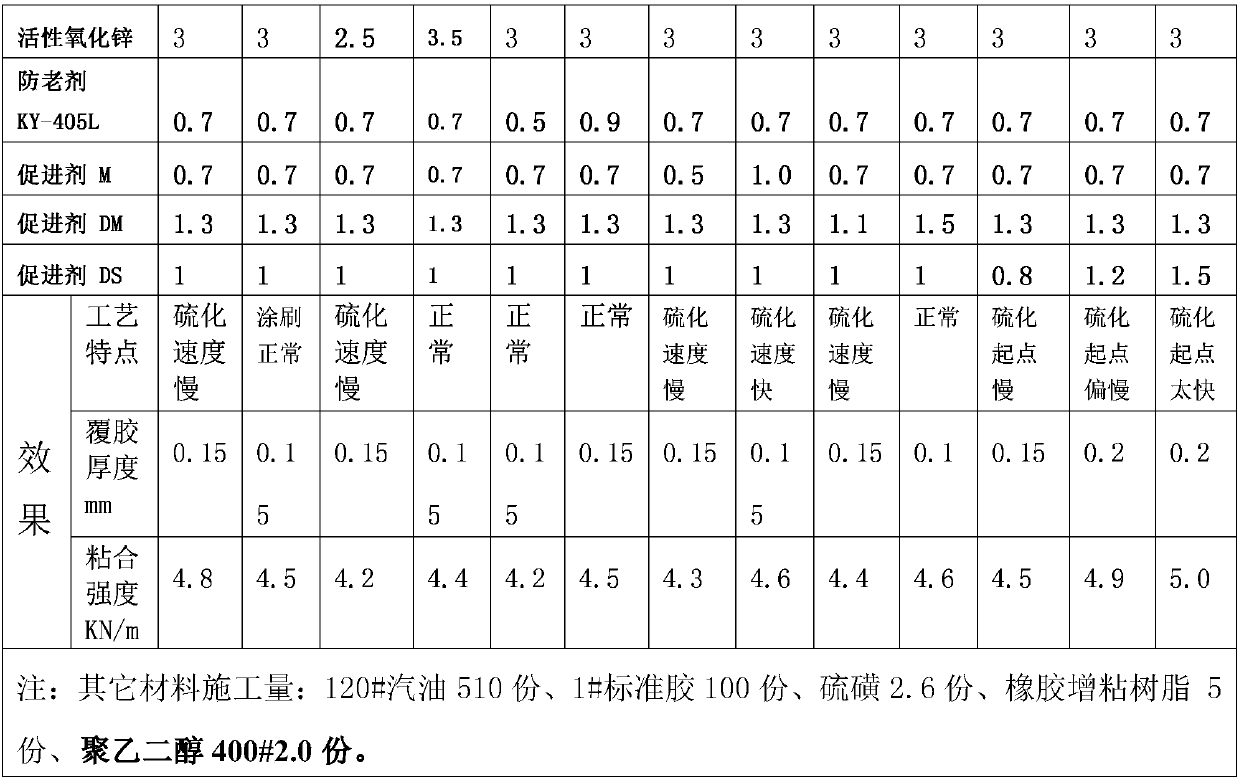

[0087] Embodiment 1 of the present invention: the adhesive for anti-static, dust-absorbing and water-blocking cloth rubber shoes, including the grafting agent for the upper fiber water-blocking coating, the bonding transition agent, the adhesive and the rubber surface treatment agent; calculated in parts by mass, The composition of the grafting agent for the water-blocking coating of the shoe upper fiber includes 5 parts of curing agent E766 and 95 parts of upper treatment agent P-206F; the composition of the bonding transition agent includes 5 parts of curing agent E766 and 95 parts of treatment agent Na-036; The agent is adhesive Na047; the composition of the rubber surface treatment agent includes 100 parts of 1# standard glue, 2.6 parts of sulfur, 5 parts of rubber tackifying resin, 3 parts of vulcanization accelerator, 4 parts of vulcanization active agent, and 4000 parts of polyethylene glycol. 2 parts, 0.7 part of antioxidant K-405L and 510 parts of 120# gasoline; every ...

Embodiment 2

[0107] Embodiment 2 of the present invention: the adhesive for anti-static, dust-absorbing and water-blocking cloth rubber shoes, including the grafting agent for the upper fiber water-blocking coating, the bonding transition agent, the adhesive and the rubber surface treatment agent; calculated in parts by mass, The composition of the grafting agent for the water-blocking coating of the shoe upper fiber includes 5 parts of curing agent E766 and 95 parts of upper treatment agent P-206F; the composition of the bonding transition agent includes 5 parts of curing agent E766 and 95 parts of treatment agent Na-036; The agent is adhesive Na047; the composition of rubber surface treatment agent includes 100 parts of 1# standard glue, 2.8 parts of sulfur, 5 parts of rubber tackifying resin, 2.8 parts of vulcanization accelerator, 4.2 parts of vulcanization activator, and 4000 parts of polyethylene glycol. 1.5 parts, 0.8 part of antioxidant K-405L and 515 parts of 120# gasoline; every 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com