High-efficient adhesive for polyester filament yarn fine cotton rubber shoes and its preparation method and using method

A polyester filament and adhesive technology, applied in the field of rubber processing, can solve the problems of poor appearance quality, low bonding strength, easy degumming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

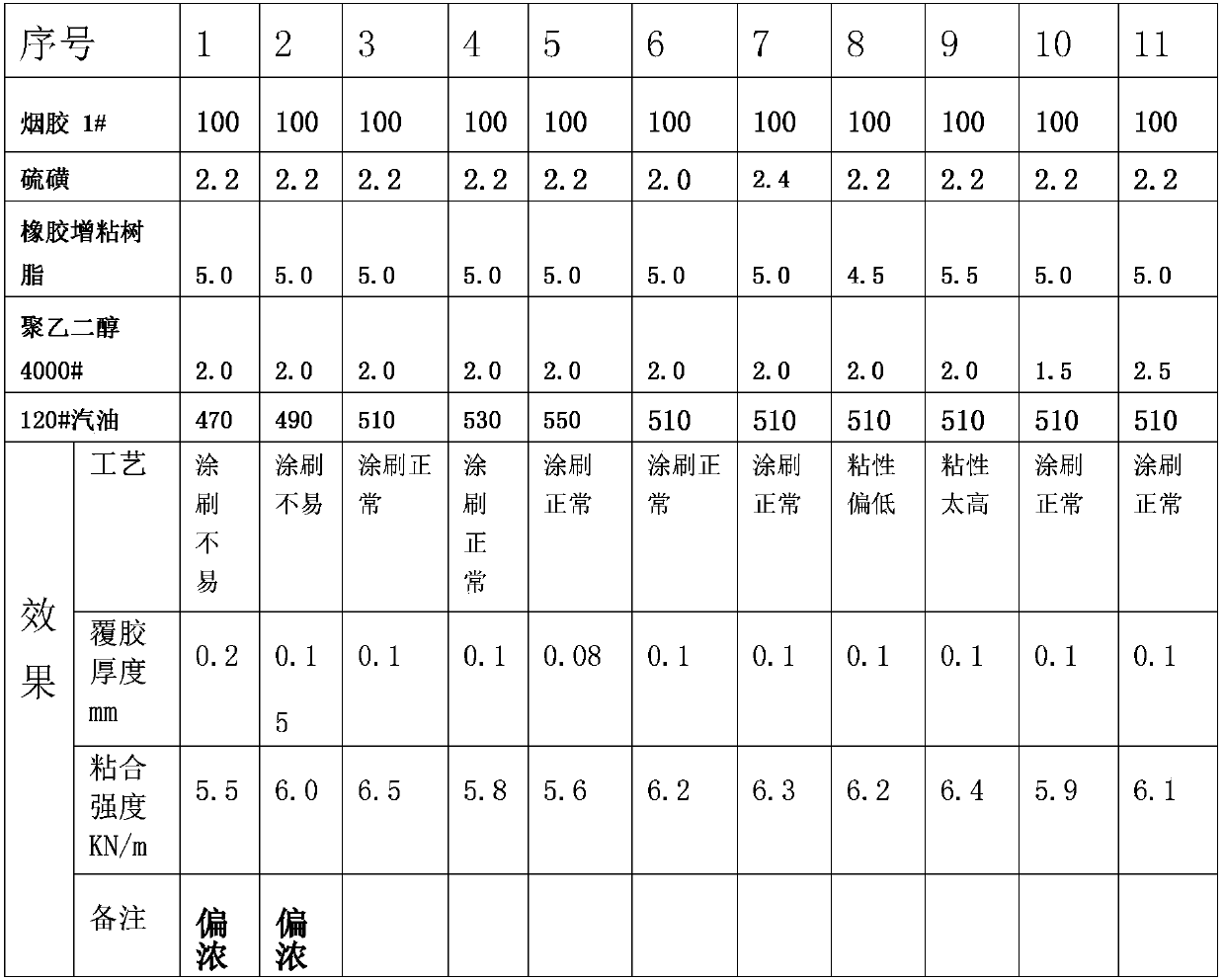

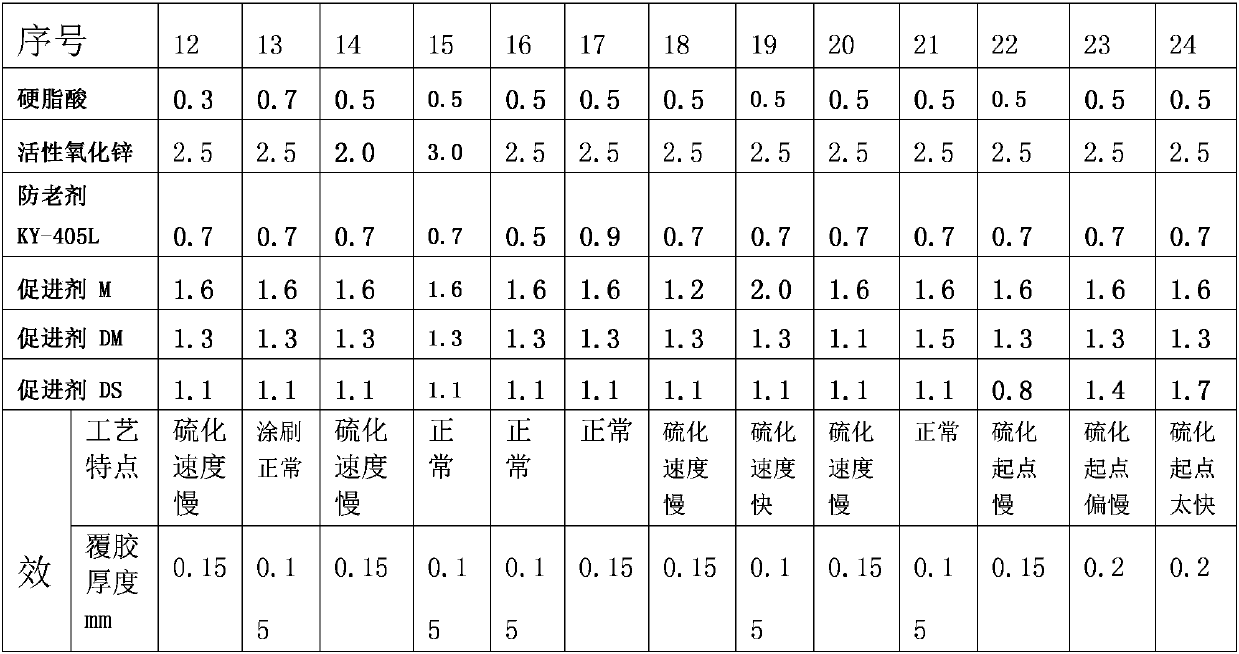

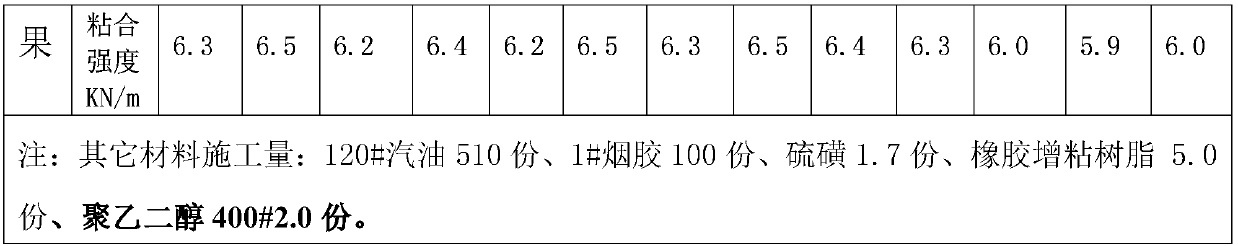

[0084] Embodiment 1 of the present invention: high-efficiency adhesive for polyester filament fine grain cloth rubber shoes, including fiber grafting agent, adhesive and rubber surface treatment agent; calculated in parts by mass, the composition of fiber grafting agent includes 10 parts of curing Agent E766 and 90 parts of shoe upper treatment agent P-135F; adhesive is adhesive Na047; the composition of rubber surface treatment agent includes 100 parts of 1# smoked rubber, 2.1 parts of sulfur, and 5 parts of rubber tackifying resin (RX-80) , 4 parts of vulcanization accelerator, 3 parts of vulcanization activator, 2 parts of polyethylene glycol 4000#, 0.7 part of antioxidant K-405L and 510 parts of 120# gasoline; every 4 parts of vulcanization accelerator consists of 1.7 parts of accelerator M, 1.3 parts of agent DM and 1.0 parts of accelerator DS; every 3 parts of active agent is composed of 2.5 parts of superfine active zinc oxide and 0.5 parts of stearic acid; the model of ...

Embodiment 2

[0104] Embodiment 2 of the present invention: high-efficiency adhesive for polyester filament fine grain cloth rubber shoes, including fiber grafting agent, adhesive and rubber surface treatment agent; calculated in parts by mass, the composition of fiber grafting agent includes 10 parts of curing Agent E766 and 90 parts of upper treatment agent P-135F; the adhesive is Na047; the composition of the rubber surface treatment agent includes 100 parts of 1# smoked rubber, 2.3 parts of sulfur, and 4.8 parts of rubber tackifying resin (RX-80) , 3.8 parts of vulcanization accelerator, 2.8 parts of vulcanization activator, 2.5 parts of polyethylene glycol 4000#, 0.8 part of antioxidant K-405L and 520 parts of 120# gasoline; every 4 parts of vulcanization accelerator consists of 1.7 parts of accelerator M, 1.3 parts of agent DM and 1.0 parts of accelerator DS; every 3 parts of active agent is composed of 2.5 parts of superfine active zinc oxide and 0.5 parts of stearic acid; the model o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesion strength | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com