Air-jet texturing yarn vamp cloth binder and application thereof

A technology of shoe upper cloth and adhesive, which is applied to the air-transformed silk shoe upper cloth adhesive and application field, and achieves the effects of improving wearing life, good adhesive strength and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

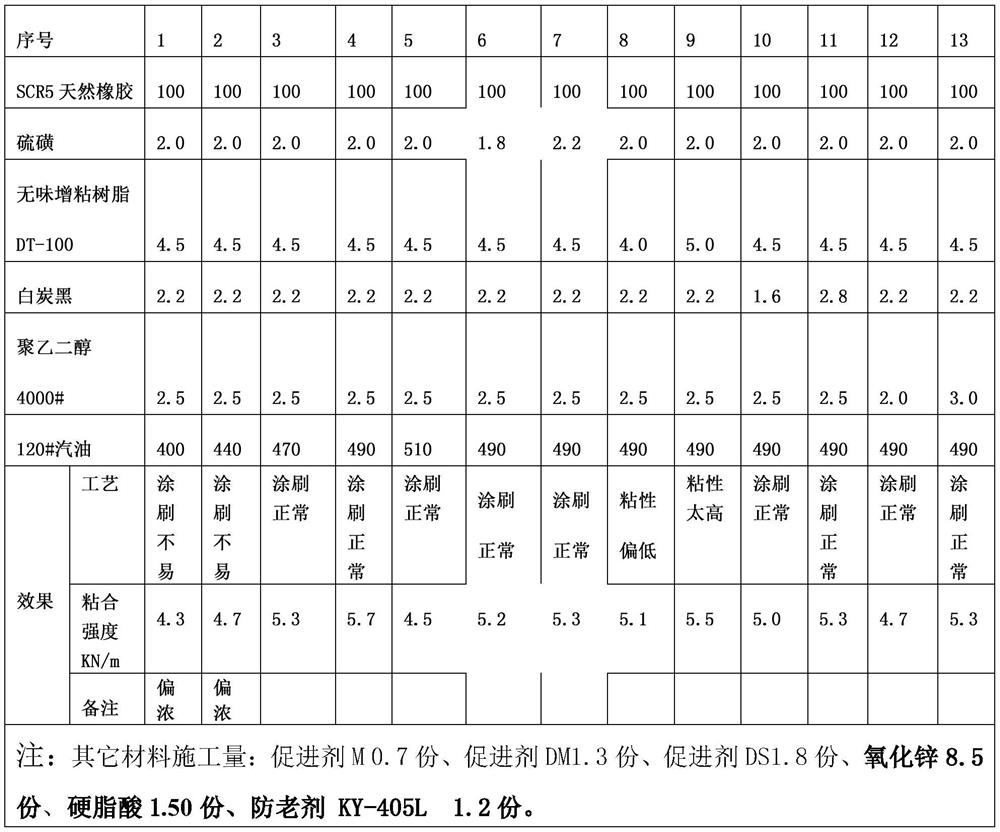

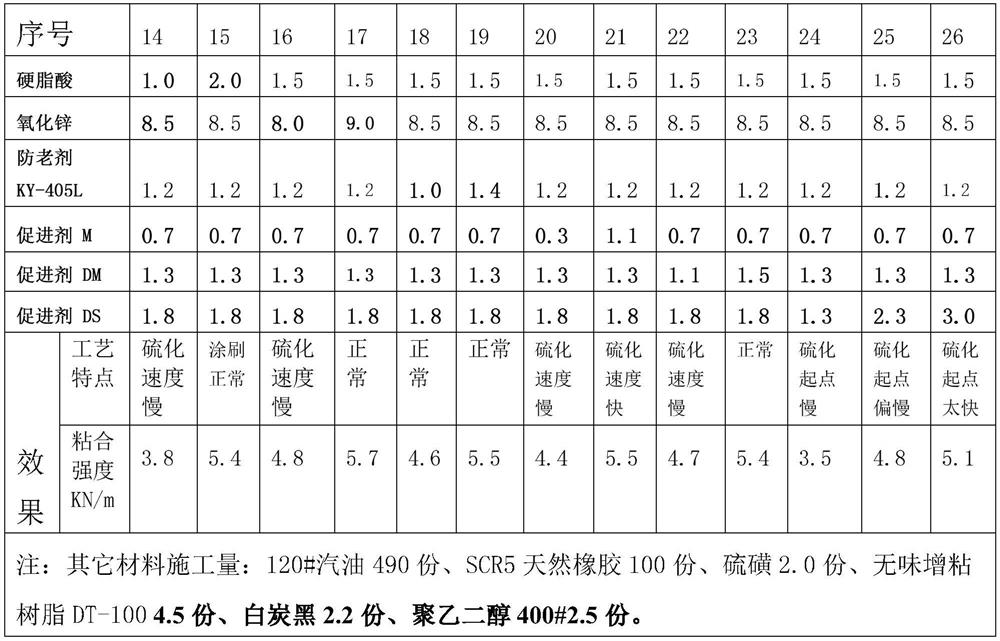

[0086] Embodiment 1 of the present invention: air variable silk upper cloth adhesive and its application

[0087] 1. Compound formula: 100 parts of SCR5 natural rubber, 2.0 parts of sulfur, 3.8 parts of vulcanization accelerator, 8.5 parts of zinc oxide, 1.5 parts of stearic acid, 2.2 parts of white carbon black, 2.5 parts of polyethylene glycol 4000#, viscosity increaser 4.5 parts of resin, 1.2 parts of anti-aging agent KY-405L, 490 parts of 120# gasoline.

[0088] 2. Process:

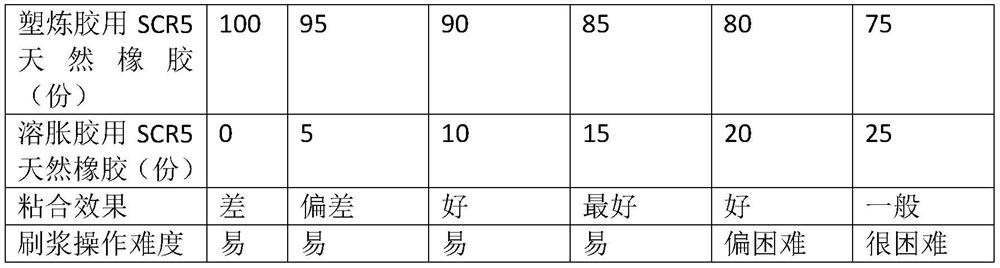

[0089] First prepare the high-viscosity rubber slurry used for the adhesive surface of the enclosure:

[0090] Preparation of gasoline mortar mixing rubber: Take 100 parts of SCR5 natural rubber, knead in an internal mixer at a mixing temperature of 80-90°C for 8-12 minutes, discharge the material to an open rubber mixing machine, roll it to smooth, and then knead The sheet is parked for 1-2 hours, then use an open rubber mixing machine to pull through 5 passes under the conditions of a roller dista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com