Polyester-cotton blended 1X1 camouflage plain cloth hot-vulcanized rubber shoe adherend and preparation method and application thereof

A technology of polyester-cotton blending and thermal vulcanization, which is applied in applications, shoe uppers, footwear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Embodiment 1 of the present invention: Polyester-cotton blended 1X1 camouflage flat cloth hot-vulcanized rubber shoe adhesive body and its shoe-making application process

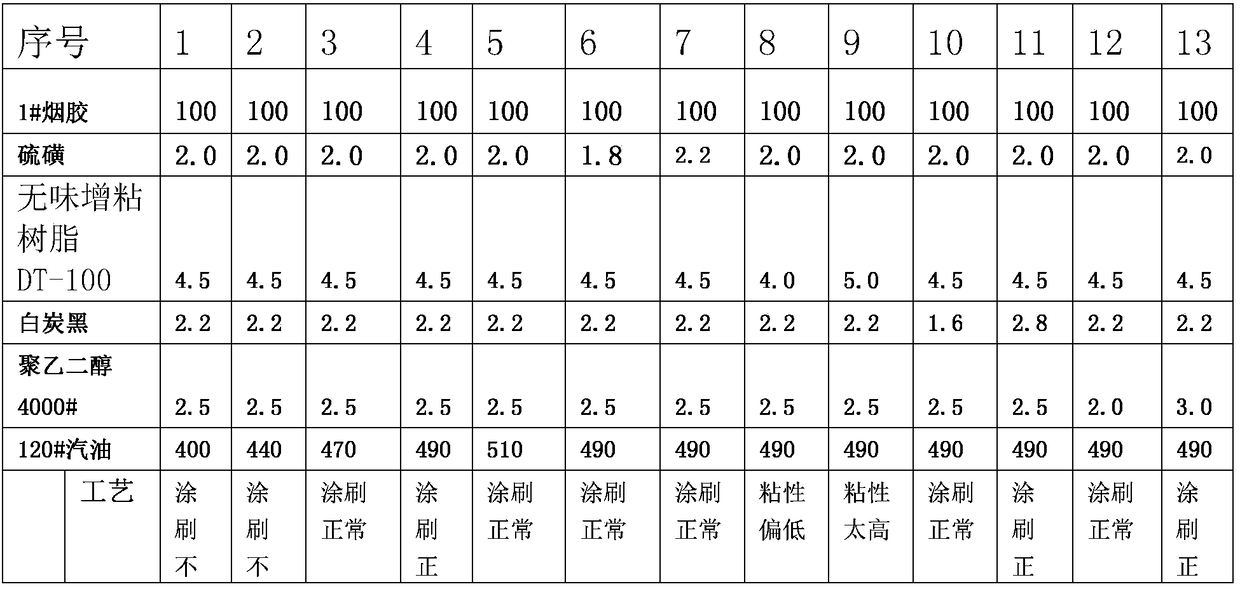

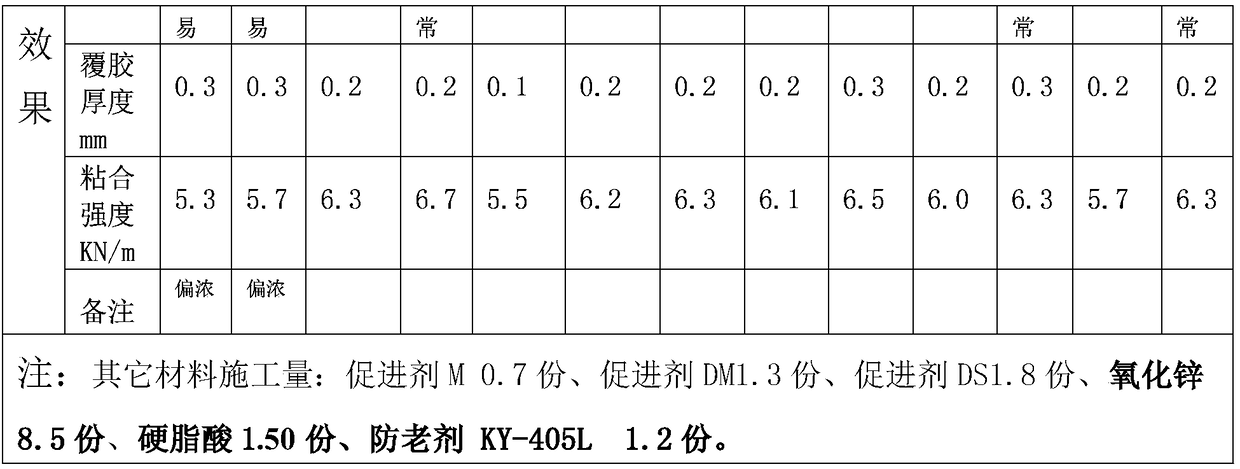

[0088] 1. Compound formula: 100 parts of 1# smoking rubber, 2.0 parts of sulfur, 3.8 parts of vulcanization accelerator, 8.5 parts of zinc oxide, 1.5 parts of stearic acid, 2.2 parts of white carbon black, 2.5 parts of polyethylene glycol 4000#, 4.5 parts of viscose resin, 1.2 parts of anti-aging agent KY-405L, 490 parts of 120# gasoline.

[0089] 2. Process:

[0090] First prepare the high-viscosity rubber slurry used for the adhesive surface of the enclosure:

[0091] (1) Preparation of 1# smoked rubber plasticizing rubber: Take 85 parts of 1# smoked rubber, press in the internal mixer at a mixing temperature of 80-90°C for 6-7 minutes, and discharge the material to the open rubber mixing machine for wrapping Refining is smooth, and then slabs are parked for 1-2 hours, then use an open rubber mix...

Embodiment 2

[0104] Then paste the adhesive surface of the brushed skirt on the surface of the Na047 adhesive on the upper of the shoe, and press it for 1.5-2 seconds under a pressure of 0.35-0.38 MPa to obtain a semi-finished rubber shoe glued to the skirt. Then put the semi-finished rubber shoes in a rubber shoe vulcanization tank at a temperature of 115° C. and a pressure of 0.38 MPa to keep the temperature and pressure for vulcanization for 45 minutes to obtain the finished rubber shoes. After the finished rubber shoes are cooled at room temperature for more than 12 hours, the adhesive strength can be measured. Embodiment 2 of the present invention: Polyester-cotton blended 1X1 camouflage flat cloth hot-vulcanized rubber shoe adhesive body and its shoe-making application process:

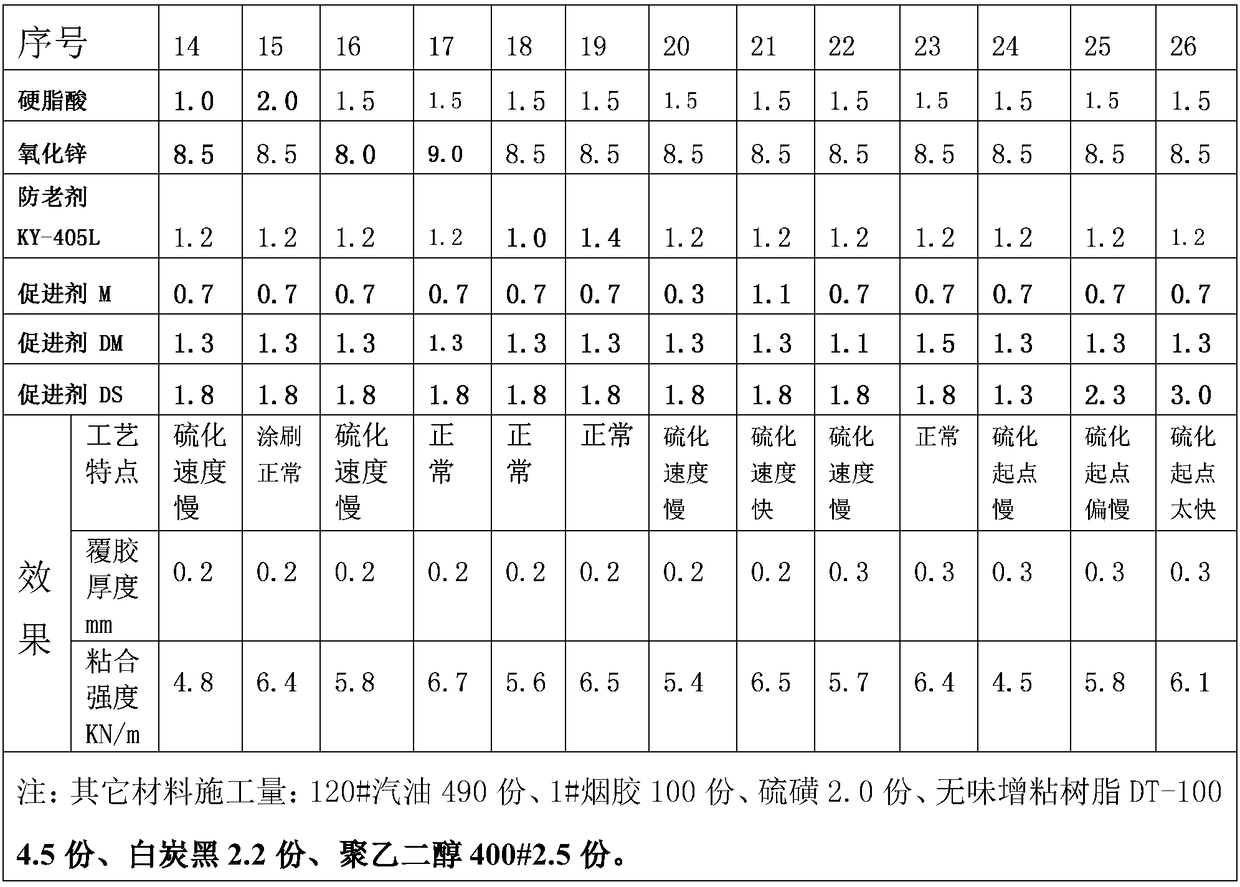

[0105] 1 Rubber material formula: 100 parts of 1# smoking rubber, 2.3 parts of sulfur, 3.8 parts of vulcanization accelerator, 6.3 parts of vulcanization activator, 2.2 parts of white carbon black, 2.5 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com