Pulping method for treating waste paper pulp by utilizing neutral cellulase and neutral xylanase

A neutral cellulase and xylanase technology, applied in the field of papermaking, can solve the problem of no obvious improvement in physical indicators such as pulp strength, and achieve the improvement of keratinization phenomenon, the enhancement of folding and bursting resistance, and the improvement of papermaking. The effect of increasing the speed of the locomotive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

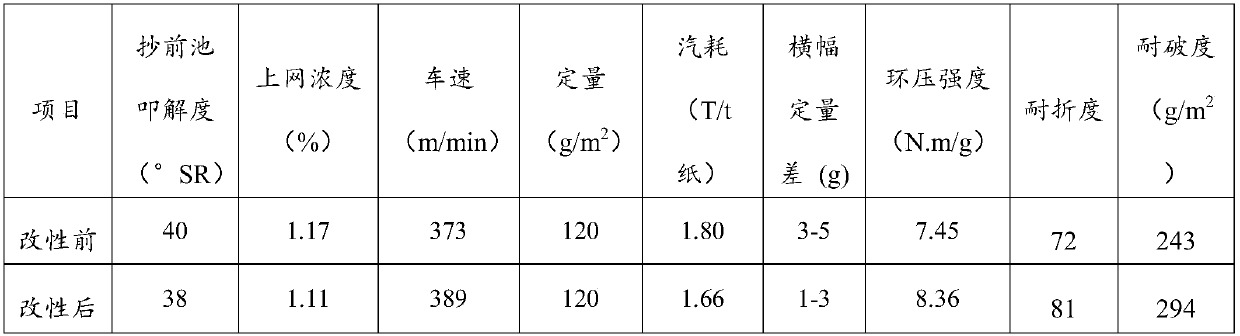

Embodiment 1

[0026] A pulping method utilizing neutral cellulase and neutral xylanase to treat waste paper pulp, comprising the following steps:

[0027] A, waste paper pulp pretreatment: add cetyl trimethyl ammonium chloride to corrugated paper waste paper pulp, the concentration of described corrugated paper waste paper pulp is 2.5%, the addition amount of described cetyl trimethyl ammonium chloride is corrugated paper 0.08wt% of the dry weight of the waste paper pulp; pulping for 15 minutes at 30°C and 200rpm / min to obtain pretreated waste paper pulp;

[0028] B. Enzymatic hydrolysis of waste paper pulp: adjust the pH value of the pretreated waste paper pulp obtained in step A to 6.5, and add the thermophilic Chaetomium cellulase and neutral xylanase at a temperature of 45°C. The thermophilic Chaetomium The added amount of cellulase is 0.1kg / t dry pulp; the added amount of neutral xylanase is 0.1kg / t dry pulp; heat preservation treatment at 220rpm / min for 55min to obtain enzymatically h...

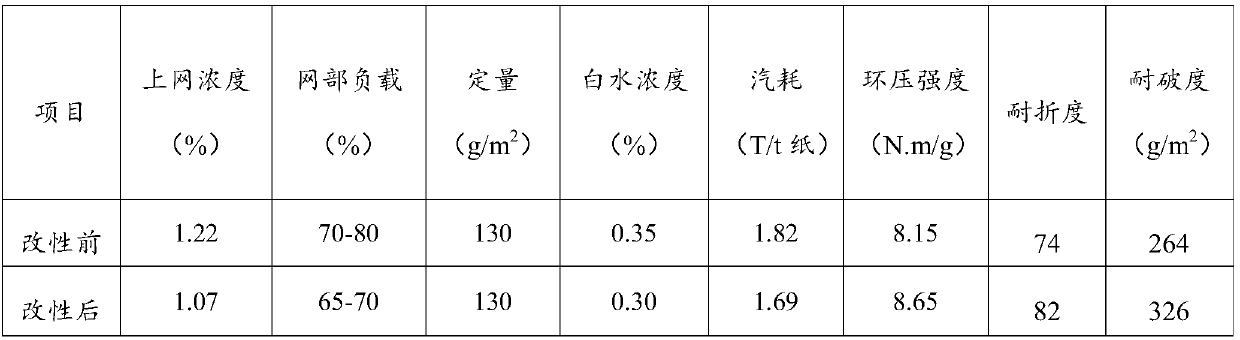

Embodiment 2

[0035] A pulping method utilizing neutral cellulase and neutral xylanase to treat waste paper pulp, comprising the following steps:

[0036] A, waste paper pulp pretreatment: add cetyl trimethyl ammonium chloride to corrugated paper waste paper pulp, the concentration of described corrugated paper waste paper pulp is 3.5%, the addition amount of described cetyl trimethyl ammonium chloride is corrugated paper 0.05wt% of the dry weight of waste paper pulp; pulping at 35°C and 180rpm / min for 20min to obtain pretreated waste paper pulp;

[0037]B. Enzymatic hydrolysis of waste paper pulp: adjust the pH value of the pretreated waste paper pulp obtained in step A to 7.5, and add the thermophilic Chaetomium cellulase and neutral xylanase at a temperature of 40°C. The thermophilic Chaetomium The added amount of cellulase is 0.3kg / t dry pulp; the added amount of the neutral xylanase is 0.05kg / t dry pulp; heat preservation treatment at 250rpm / min for 40min to obtain enzymatically hydrol...

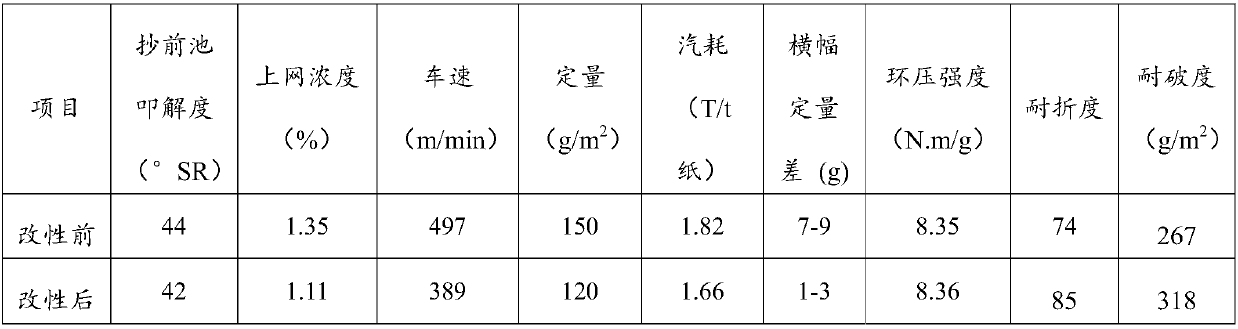

Embodiment 3

[0044] A pulping method utilizing neutral cellulase and neutral xylanase to treat waste paper pulp, comprising the following steps:

[0045] A, waste paper pulp pretreatment: add cetyl trimethyl ammonium chloride to corrugated paper waste paper pulp, the concentration of described corrugated paper waste paper pulp is 3%, the addition amount of described cetyl trimethyl ammonium chloride is corrugated paper 0.07wt% of waste paper pulp dry weight; pulping at 32°C and 190rpm / min for 17min to obtain pretreated waste paper pulp;

[0046] B. Enzymatic hydrolysis of waste paper pulp: adjust the pH value of the pretreated waste paper pulp obtained in step A to 7, and add the thermophilic Chaetomium cellulase and neutral xylanase at a temperature of 42°C. The thermophilic Chaetomium The addition amount of cellulase is 0.2kg / t dry pulp; the addition amount of the neutral xylanase is 0.075kg / t dry pulp; heat preservation treatment at 235rpm / min for 47min to obtain enzymolysis waste paper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com