Hydraulic rush spray device

A hydraulic and blower technology, used in wellbore/well components, earth-moving drilling, sealing/packing, etc., can solve the problems of harmful gases, life and property environmental pollution, and easy changes in internal structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

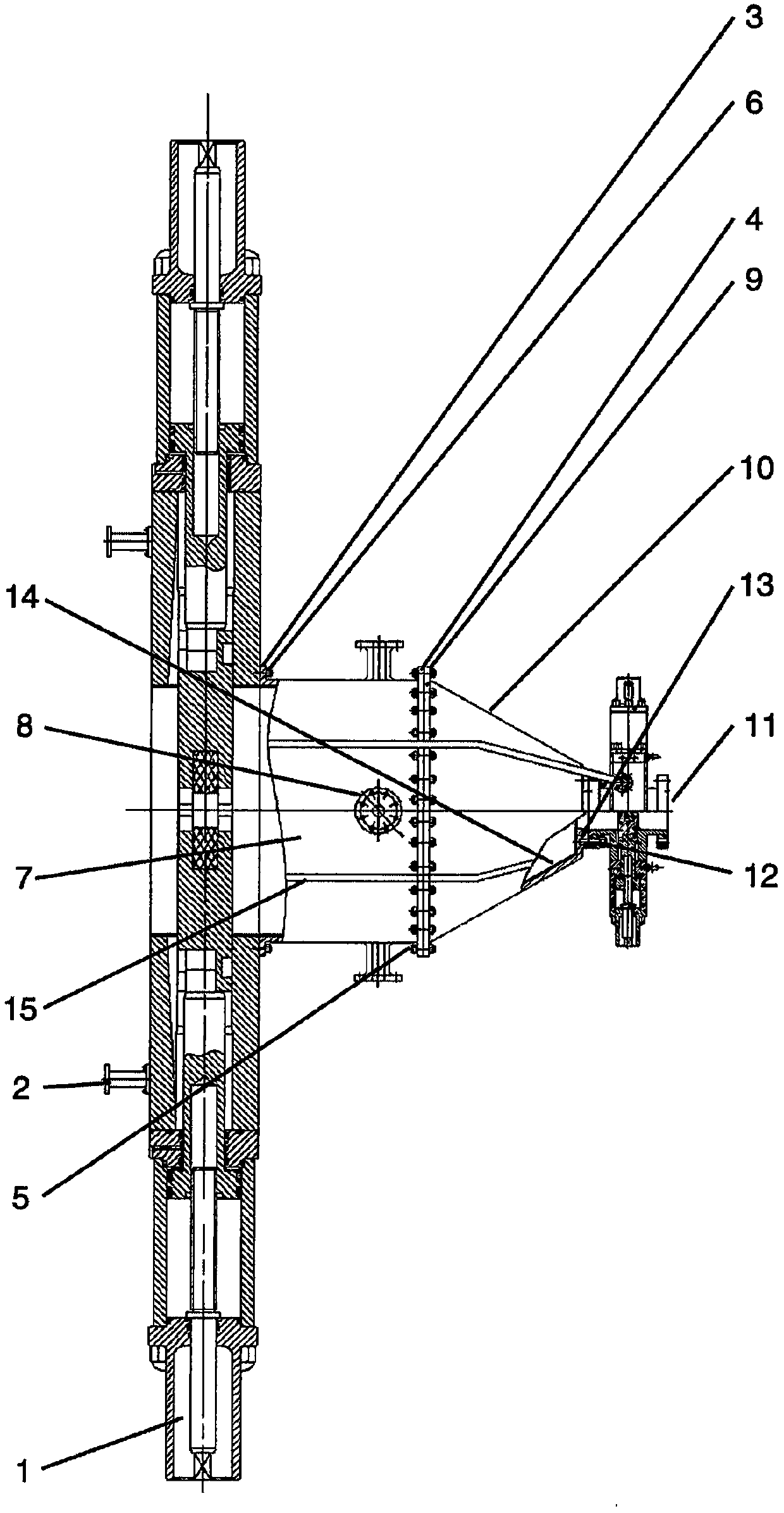

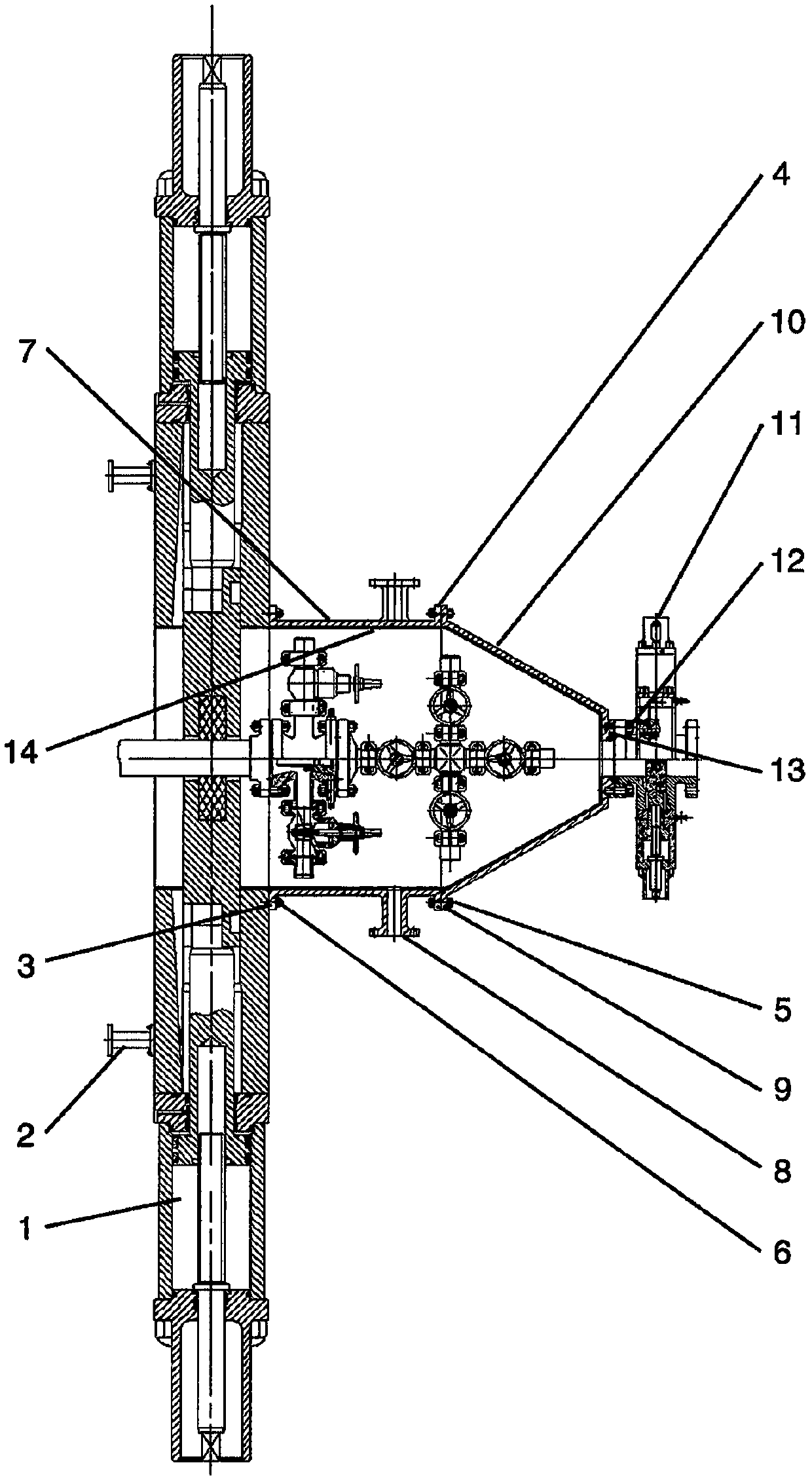

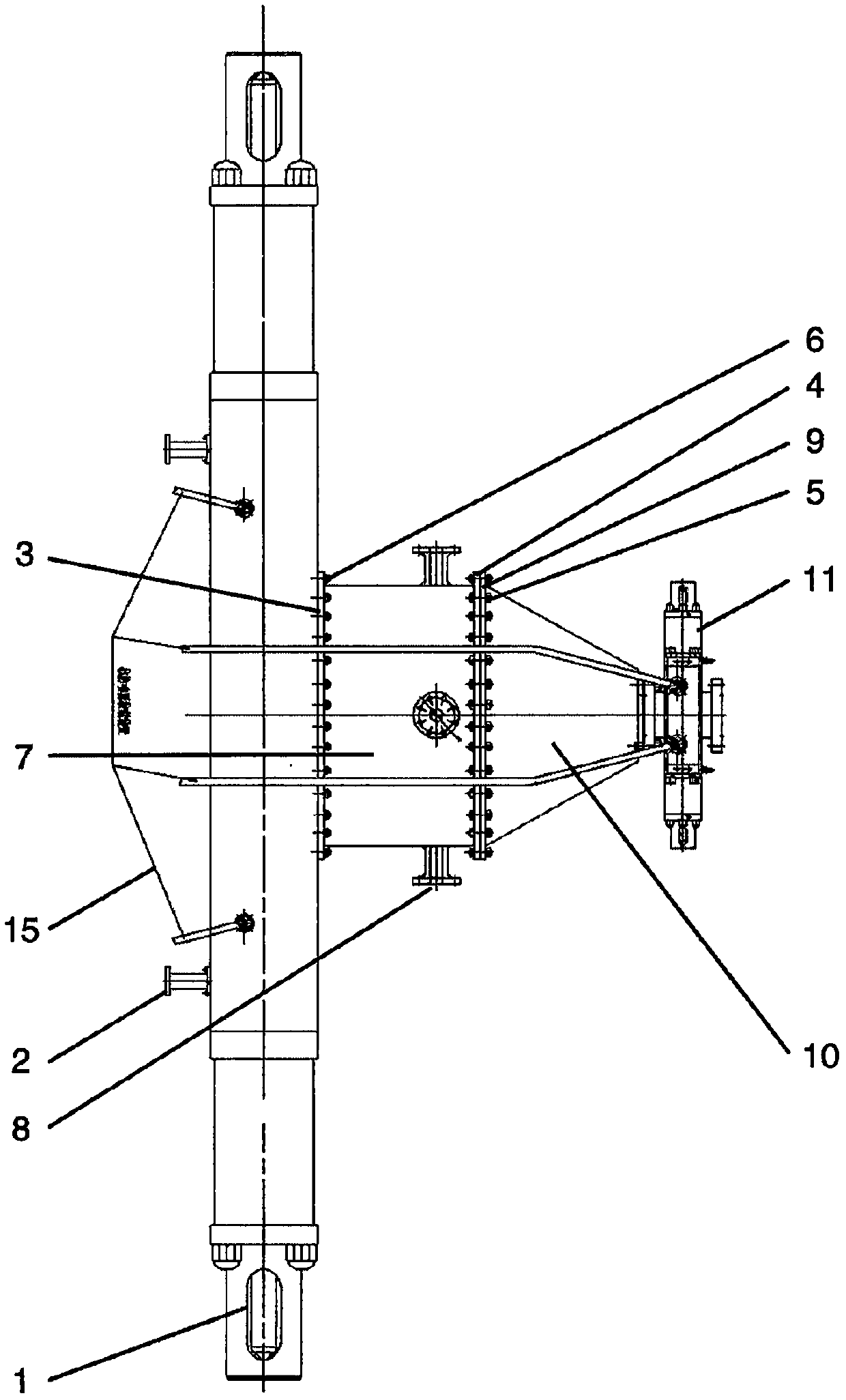

[0011]In the figure: a hydraulic spraying device includes a connecting cylinder, a fully sealed blowout preventer 11 and a half sealed blowout preventer 1. The connecting cylinder includes a circular cylinder 7 and a cone-shaped cylinder 10 . The circular cylinder has a double-flange structure, that is, the two cylinder mouths of the circular cylinder, one is the upper cylinder mouth, the other is the lower cylinder mouth, the upper cylinder mouth and the lower cylinder mouth are respectively flange structures, and bolt holes are evenly distributed on the flange structures; There are outwardly protruding spraying connection ports 8 on the circular cylinder, and there are four spraying connection ports, which are opposite to each other to form two pairs of spraying connection ports, that is, one pair is the front and rear sides of the circular cylinder. Connecting port, the other pair is the spraying connection port on the left side and the right side of the circular cylinder. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com