Fluid container having device for fill level monitoring

A fluid container, filling level technology, applied in the direction of buoy level indicator, liquid/fluid solid measurement, measuring device, etc., can solve the leakage signal, undetected, unreliable detection of position encoder clogging or Blockage and other problems, to achieve the effect of large filling height, simple design, and reduced size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

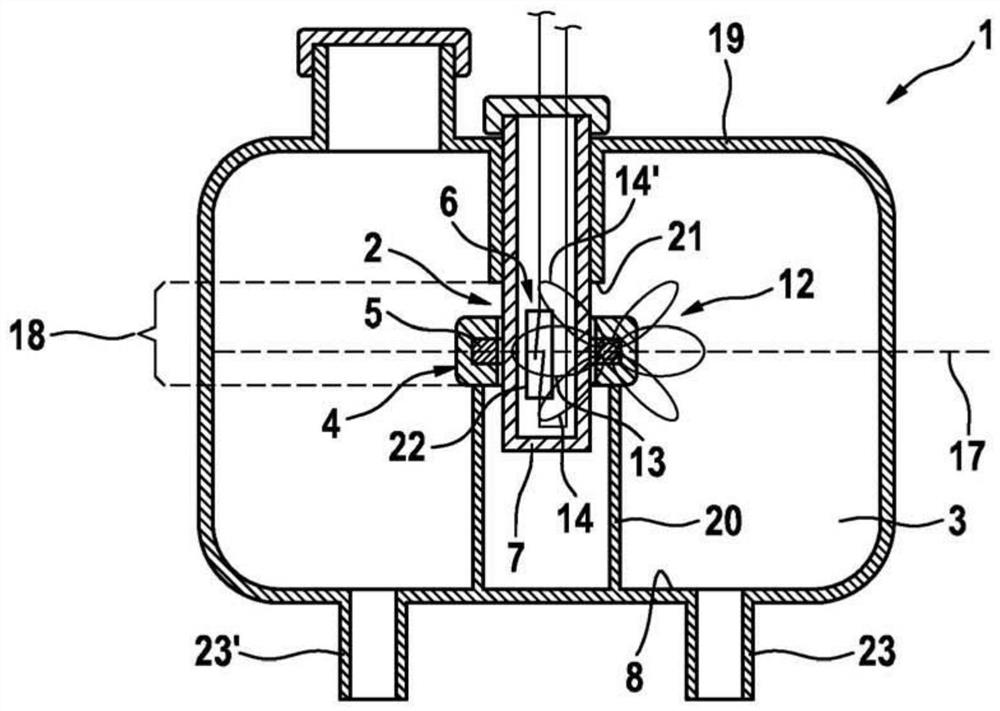

[0025] figure 1

[0026] The known fluid container 1 has a housing 19 which can be filled with a fluid. The hydraulic ports 23, 23' connect the interior space 3 of the container 19 to a braking system (not shown here) and enable circulation of fluid. In order for the brake system to function reliably, a minimum amount of fluid is required which defines a minimum fill level in a manner dependent on the state of the container 19 and possibly on a defined safety factor in the housing 19 .

[0027] The conduit 7 is arranged vertically aligned in the inner space 3 of the housing 19 . The signaling unit 6 with the reed switch 22 is accommodated in the conduit 7 . Through its position, the reed switch 22 defines a switching point 17 which is arranged at the height of the minimum fill level to be monitored by the structural design.

[0028] Position encoder 4 is guided on conduit 7 . The position encoder 4 is designed as an annular float which floats on the surface of the fluid s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com