Inter-stage seal structure device of double-pulse solid rocket engine

A solid rocket and interstage sealing technology, which is applied to rocket engine devices, machines/engines, jet propulsion devices, etc., can solve problems such as high cost, engine scratches, and poor workmanship of ceramic partitions, so as to achieve simple structure and avoid blockage open effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

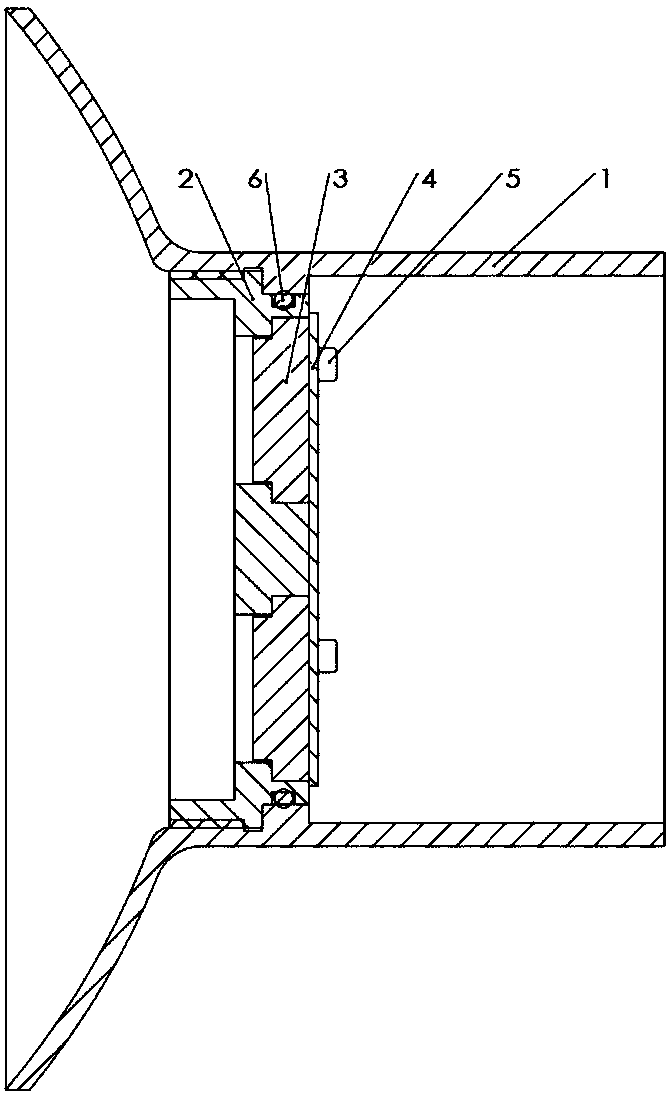

[0025] A double-pulse solid rocket motor interstage sealing structure device of the present invention comprises: a metal blocking plate 2 , a non-metallic blocking plate 3 , a blocking plate diaphragm 4 , diaphragm bolts 5 , and an O-shaped sealing ring 6 .

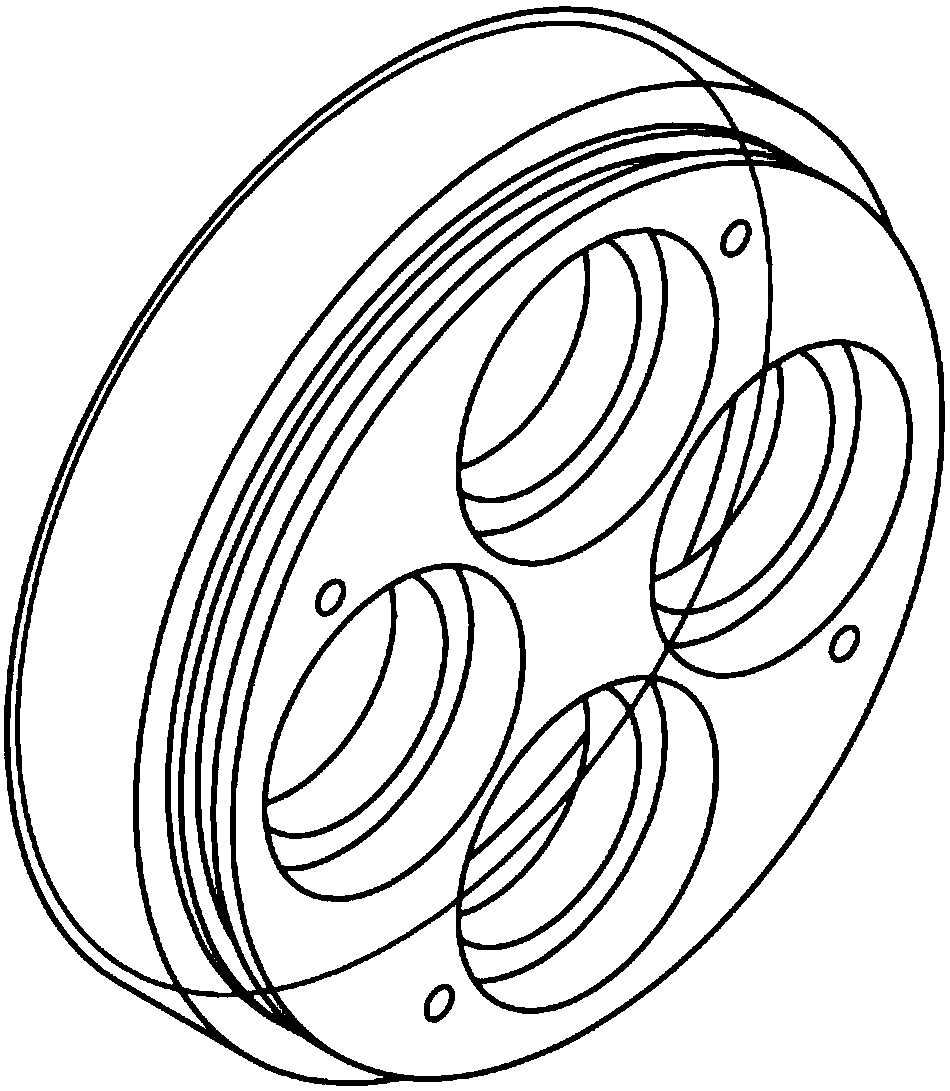

[0026] Connection relationship: the metal blocking plate 2 has 4 stepped through holes uniformly distributed in the circumferential direction, the non-metallic blocking plate 3 has a cylindrical step structure, and the four non-metallic blocking plates 3 and the 4 stepped through holes on the metal blocking plate 2 are connected. Gap fit, the gap is coated with sealant for sealing, and the step structure is used to realize the axial limit and fixation; the blocking plate diaphragm 4 is a very thin (0.3mm) circular cake-shaped structure, and 4 semicircles are evenly distributed in the circumferential direction near the outermost ring Groove, the end face of the large hole of the metal blocking plate 2 is uniformly distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com