Minor axis draught fan with motor being rear-mounted

A rear-mounted, short-shaft technology, applied in the direction of machines/engines, pump devices, mechanical equipment, etc., can solve the problems that the air flow cannot be in the fresh air flow, the safety factor is low, and the cooling of the secondary fan is difficult, so as to achieve stable motor temperature, The cooling system is smooth and the safety factor is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

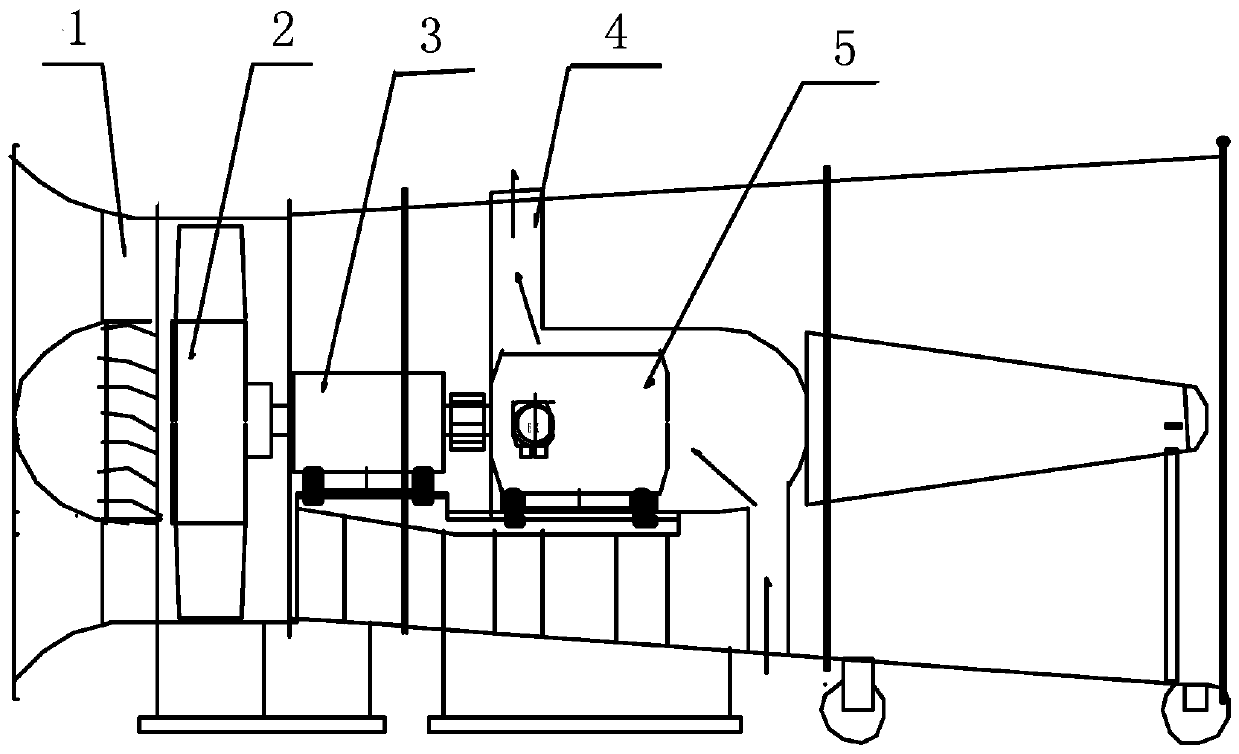

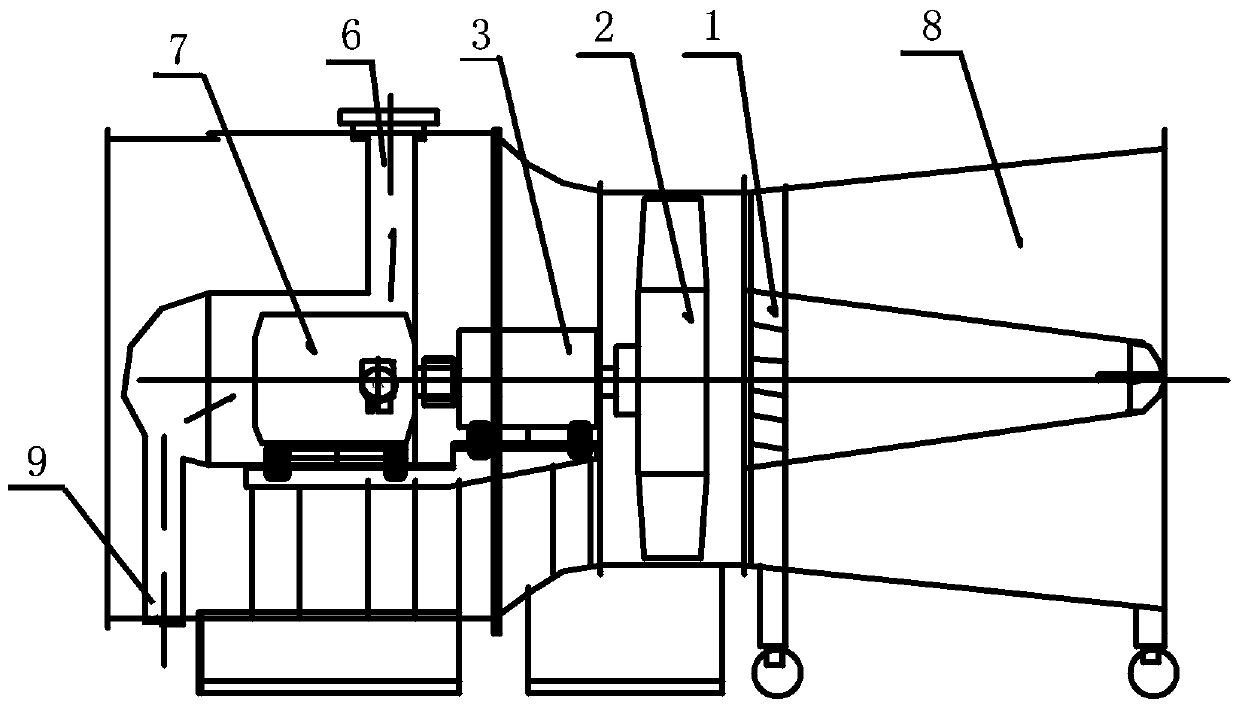

[0013] figure 2 It is a structural schematic diagram of an embodiment of the present invention; a short-axis fan with a rear motor in the present invention includes guide vanes, impellers, bearing seats, motor cooling air ducts, explosion-proof motors, diffusers, and motor cooling air inlets. It is characterized in that: explosion-proof The motor 7 is at the air inlet, and the order of the components is: explosion-proof motor 7, bearing housing 3, impeller 2, guide vane 1, diffuser 8; there is a motor cooling air duct 6 above the explosion-proof motor 7, and a motor cooling air inlet 9 below, The explosion-proof motor 7 is connected with the impeller 2 through the bearing housing 3, the impeller 2 is aligned with the guide vane 1, and the guide vane 1 is connected with the diffuser 8. In this way, the air flow flowing in the motor sealing chamber can be in the fresh air flow, and inflammable and explosive gas and downhole dirty air cannot enter the motor sealing chamber under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com