Shaft sleeve

A shaft sleeve and integrated technology, applied in the direction of shafts, bearings, bearing components, etc., can solve the problems of inconvenient installation and achieve the effect of convenient installation, simple structure and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

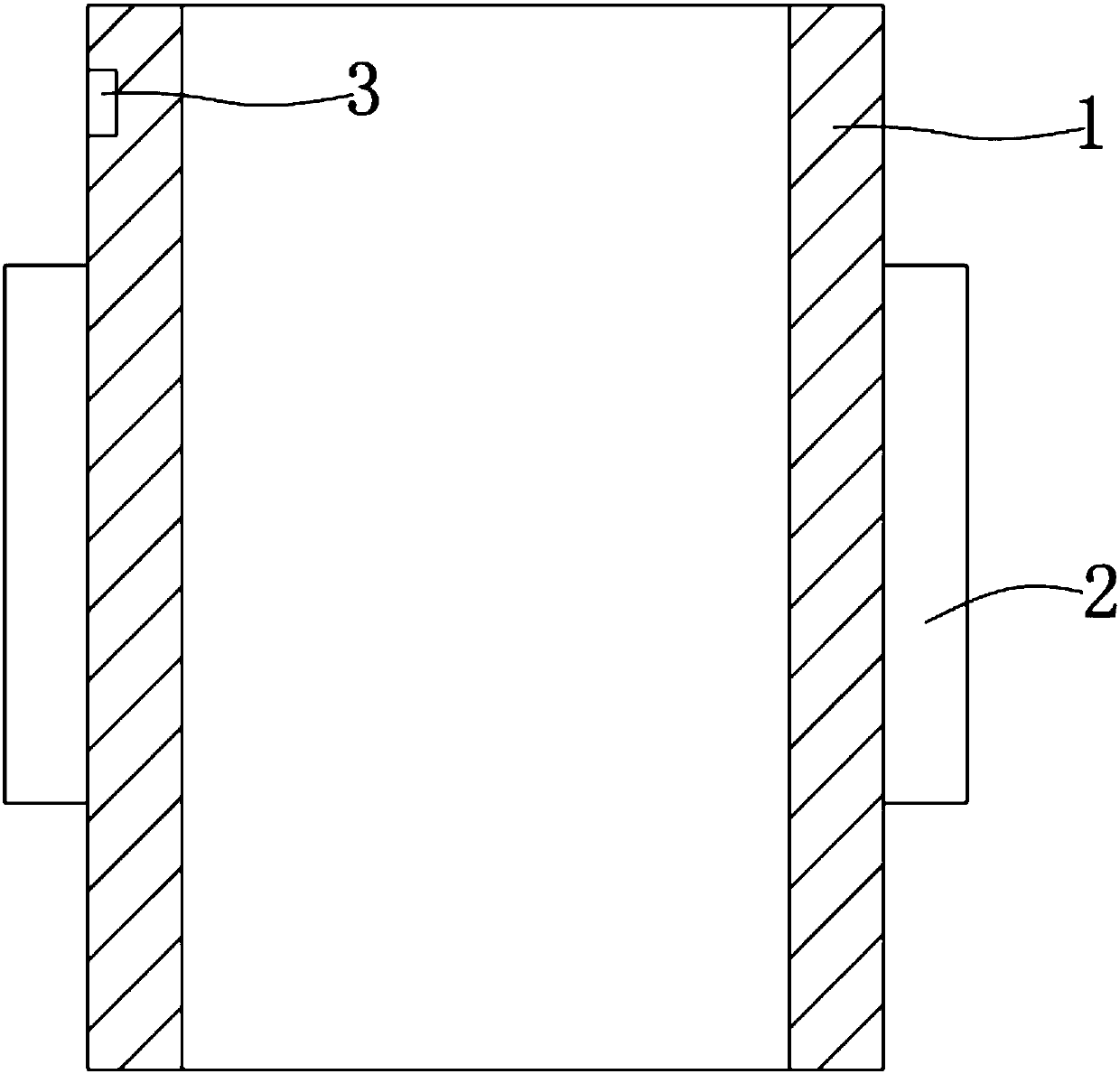

[0012] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0013] like figure 1 As shown, a bushing of the present invention includes a bushing body 1, the outer wall of the bushing body 1 is provided with a groove 2, and the groove 2 is integrally formed with the bushing body 1; the bushing body 1. The inner diameter is 25 mm; a groove 3 is also provided on one side of the outer wall of the main body 1 of the sleeve.

[0014] The sleeve main body 1 is made of iron alloy material. The length of the sleeve main body 1 is 65mm.

[0015] The shaft sleeve of the invention has simple structure, convenient installation and high strength.

[0016] In summary, the above-mentioned embodiments are not limiting embodiments of the present...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Body length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com