Low-cost gear box

A gear box, low-cost technology, applied to belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problems of high cost, difficult machining of square shafts, poor reliability of connection methods, etc. Achieve the effect of low strength, low processing difficulty and strong torsion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

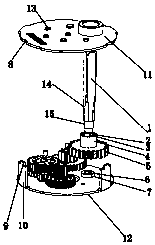

[0007] With reference to shown in Fig. 1, a kind of gear box of present embodiment comprises a gear box body, and described gear box body includes gear 5, axle 1, and described gear 5 is integrally provided with boss 2, and described gear 5 is provided with a through hole in the center, and the center of the boss 2 is provided with a square installation hole 3, and the installation hole 3 communicates with the through hole, and the shaft 1 includes a first installation part 14 and a second installation part 15. The first installation part 14 is adapted to the square installation hole 3, and the second installation part 15 is adapted to the through hole.

[0008] By adopting the above technical solution, when installing the gearbox, the first mounting part 14 of the shaft 1 fits into the square mounting hole 3, and at the same time, the second mounting part 15 of the shaft 1 fits into the through hole, and finally conflicts with the lower end cover 12 connection, gear 5 and bos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com