Novel engineering production pressure calibrator

A calibrator and engineering technology, applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve the problems of enterprise loss, difficult pressure instrument regular calibration, cycle interval safety hazards and other problems, and achieve the effect of improving the output torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

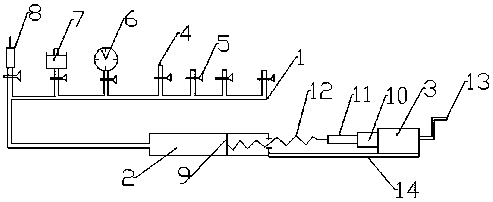

[0012] see figure 1 , the present invention provides a technical solution: a novel engineering production pressure calibrator, comprising an oil pipe 1, a piston cavity 2 and a stepping motor 3, the oil pipe 1 is connected with a measuring tube 4, and the measuring tube 4 is arranged below There is a pressure valve 5, and one of the measuring tubes 4 is connected to a calibrated pressure gauge 6, the measuring tube 4 on the left side of the calibrated pressure gauge 6 is provided with an oil cup 7, and the measuring tube 4 on the left side of the oil cup 7 A piezoelectric sensor 8 is arranged on the top, the oil pipe 1 is connected to a piston chamber 2, and a pressurizing piston 9 is arranged inside the piston chamber 2, and the stepping motor 3 is connected with a coupling 11 through a gear transmission mechanism 10 The shaft coupling 11 is connected with a lead screw 12, the right side of the stepping motor 3 is connected with a manual handle 13, and a sliding guide rail 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com