A method for manufacturing a flexible variable-angle array diffractive optical device made of PDMS material

A technology of diffractive optics and manufacturing methods, which is applied in the field of manufacturing diffractive optical devices with flexible variable-angle arrays of PDMS materials, and can solve the problems of inability to perform full-band speckle suppression, insufficient speckle suppression effect, and large number and types of devices. , to achieve the effect suitable for mass production, stable speckle suppression effect, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

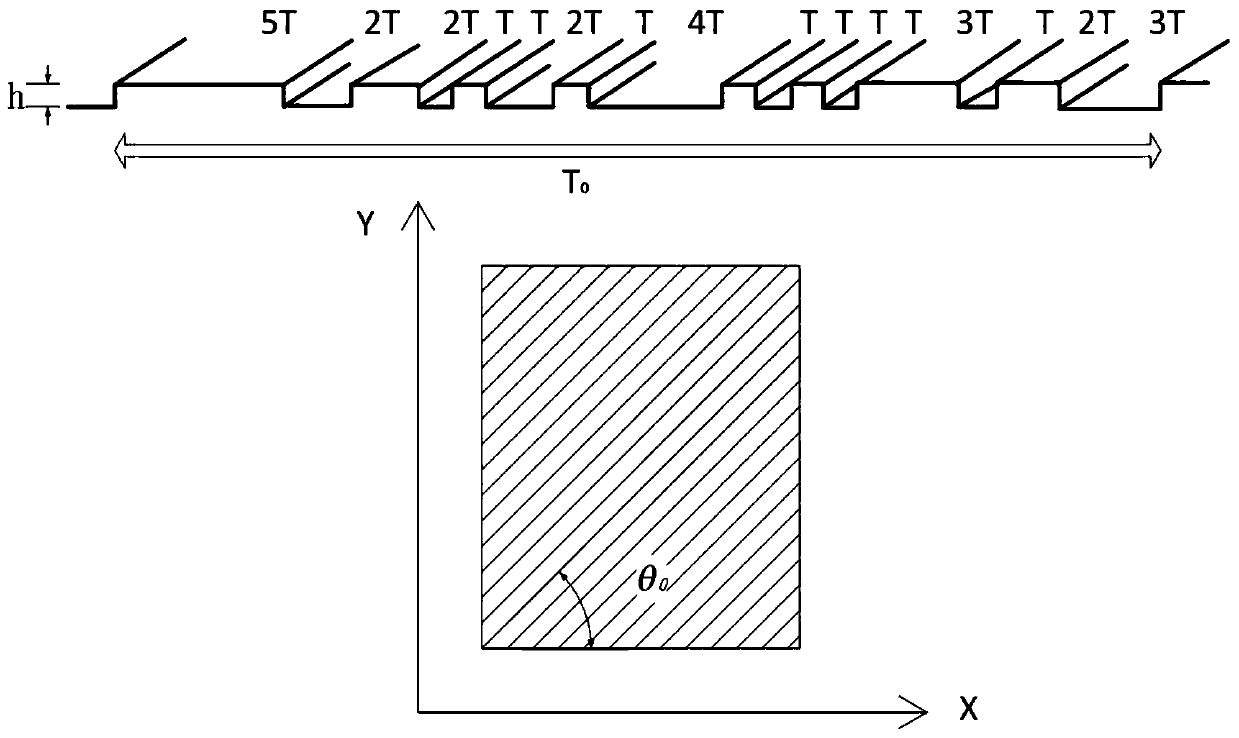

[0060] A flexible variable-angle array diffractive optical device for laser speckle suppression, made on polydimethylsiloxane (PDMS) material, and composed of three groups of one-dimensional binary diffractive optical structures connected end to end. The one-dimensional binary diffractive optical structure is an optical microstructure based on the M sequence (see attached figure 1 And attached figure 2 ), its one-dimensional binary diffractive optical structure pattern is represented by the parameter T, and the parameter T is the minimum unit width of the optical microstructure, and the width of all optical microstructures is represented by an integer multiple of T, and the one-dimensional binary The total width of the diffractive optical structure pattern is T 0 express. The depth of the one-dimensional binary diffractive optical structure is h, and the inclination angle between the one-dimensional binary diffractive optical structure and the X axis is θ 0 .

[0061] The...

Embodiment 2

[0074] The depth h of the one-dimensional binary diffractive optical structure is 480 nanometers, the curing temperature in Step 6 of the manufacturing process is 70 degrees, and the curing time is 70 minutes. Other implementation parameters and processes are the same as in Example 1.

Embodiment 3

[0076] The depth h of the one-dimensional binary diffractive optical structure is 520 nanometers, the curing temperature in step 6 of the manufacturing process is 90 degrees, and the curing time is 50 minutes. Other implementation parameters and processes are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com