Linear motor

A linear motor and coil technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of limiting the degree of freedom of linear motors and small thrust constant in the Y direction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

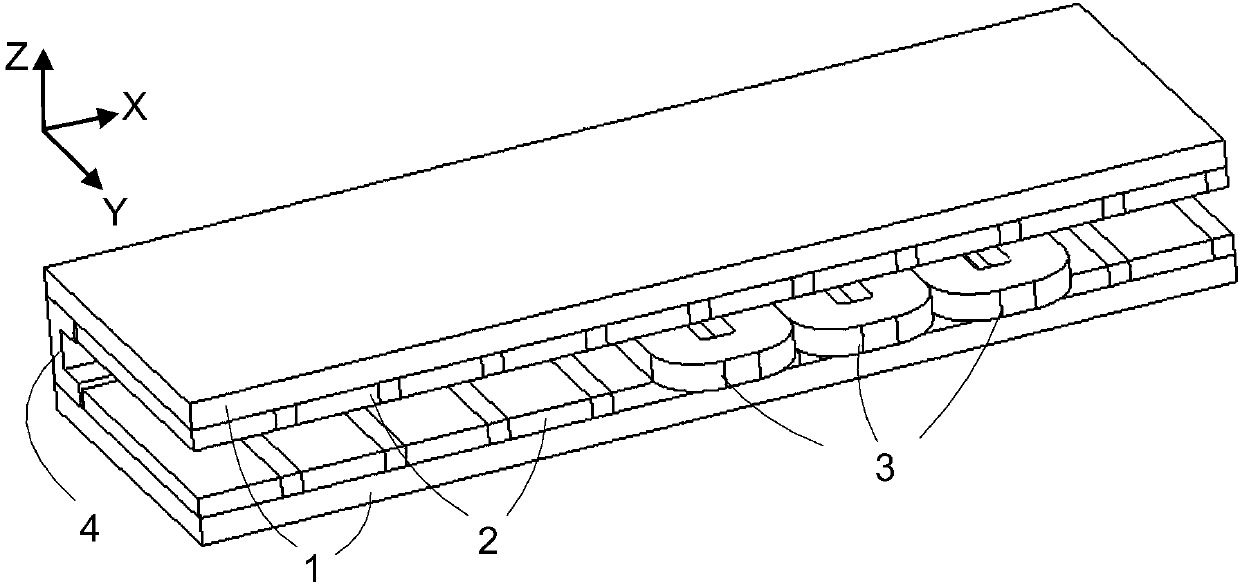

[0045] Figure 4 It is a schematic diagram of the structure of a linear motor in this embodiment. The electromagnetic structure is mainly composed of three parts, including four back irons 41 and magnet groups (the first magnet group 431, the second magnet group 432, 433, 434, and the third magnet group 435) and the coil set 42 . The second magnet group 433 connects the second magnet group 432 and the second magnet group 434 to form a V-shaped structure with a certain angle. The range of the formed angle is 0°≤α<180°, where α is the angle formed by the second magnet group 432 and the second magnet group 434 . The first magnet group 431 is parallel to the second magnet group 432 , the third magnet group 435 is parallel to the second magnet group 434 , and the first magnet group 431 and the third magnet group 435 are respectively located outside the V-shaped structure.

[0046] Optionally, both the first magnet group 431 and the third magnet group 435 include several cuboid ma...

Embodiment 2

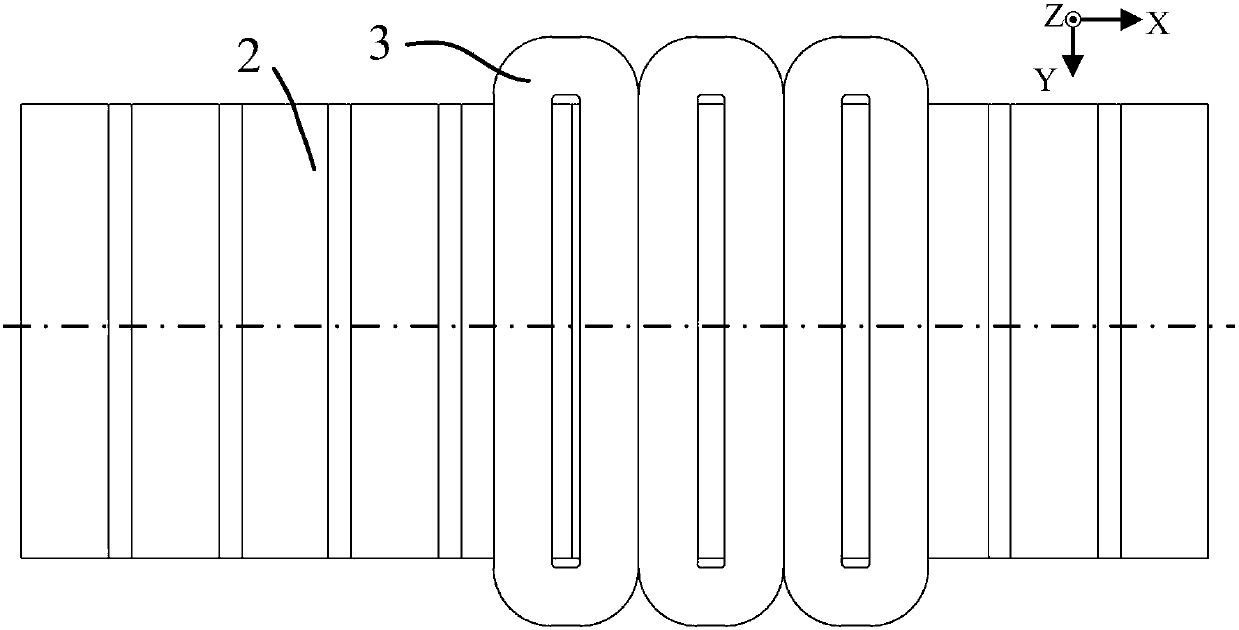

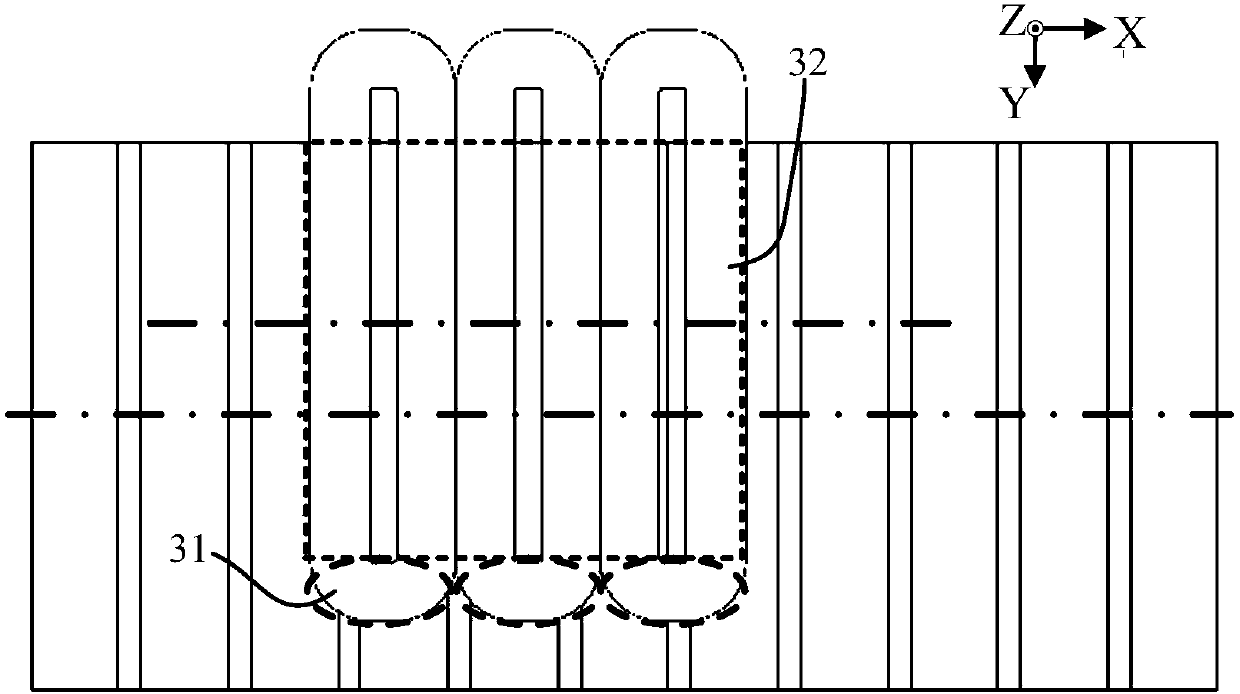

[0073] Figure 8 It is a structural diagram of a two-degree-of-freedom linear motor in Embodiment 2 of the present application. It mainly includes a back iron 41, a magnet group and a U-shaped coil group 42. This structure bends the coil group 42 by 180° to reach the coil group 42. The two arc transitions are completely parallel. At the same time, the magnet group of the motor has also changed. In this example, the fan-shaped magnet has been changed to a common rectangular magnet, which is easy to manufacture and easy to produce.

[0074] Figure 9 It is the electromagnetic structure diagram of the two-degree-of-freedom linear motor in this embodiment. The motor is mainly composed of a first magnet group 431, a second magnet group 432, a third magnet group 433, a fourth magnet group 434, and a fifth magnet group 435. The pole pitches of the group magnet groups are equal, and they are all composed of Helen Baker magnet groups. N and S in the diagram represent the magnetic pro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap