Durable icephobic surfaces

A durable, interfacial technology that can be used in other chemical processes, coatings, chemical instruments and methods to solve problems such as low ice adhesion strength, increased ice adhesion strength, and impracticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

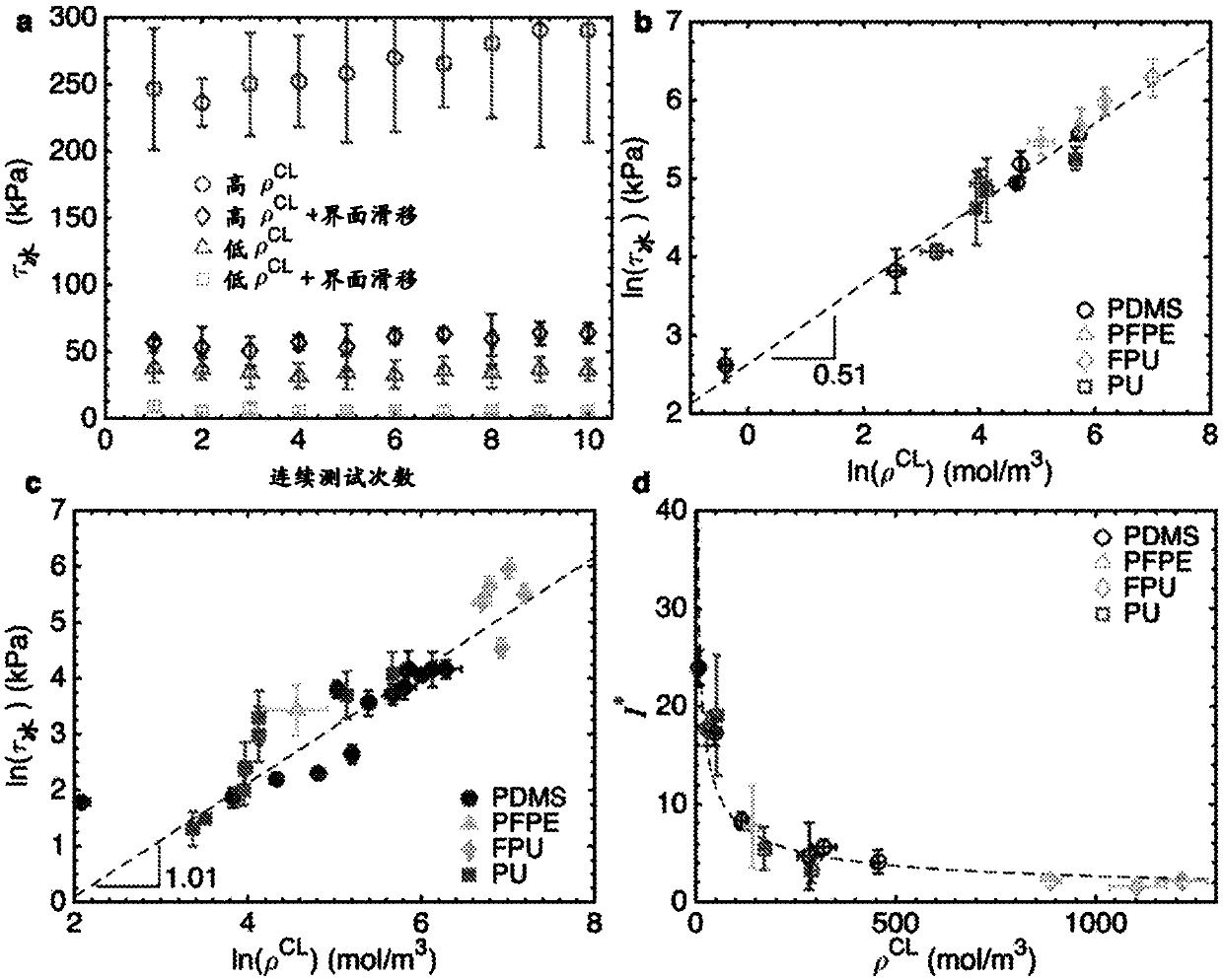

[0102] Polydimethylsiloxane (SYLGARD TM 184 or SYLGARD TM 527, ex Dow Corning), silicone oil (viscosity from 5 cP to 10,000 cP, ex Sigma Aldrich) and polymethylhydrogensiloxane (PMHS, ex Sigma Aldrich) were used as received. SYLGARD TM 184 is the basic component: cross-linking agent ratio of 10:1 cross-linked PDMS, SYLGARD TM 527 is a crosslinked PDMS with a base:crosslinker ratio of 1:1. The cross-linking agent used for both products contains effective control of the cross-link density ρ CL Copolymer of PDMS and PMHS. The mixing of these two formulations can change ρ without deviating from the stoichiometry CL , as described in Palchesko, R. et al., "Development of Polydimethylsiloxane substrate with tunable elastic modulus to study cell mechanobiology in muscle and nerve." PLoS One 7, p.e51499, (2012), which is incorporated herein by reference. In order to increase the crosslink density ρ CL , PMHS can be added with high temperature (150°C) curing.

[0103] Curin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com