Oral therapeutic MTA conveying plate

An oral treatment and conveying plate technology, applied in medical science, dentistry, protective layer, etc., can solve the problems of waste, small effective usage, and increase the clinical cost of patients, so as to avoid a lot of waste, facilitate push, and facilitate clinical use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

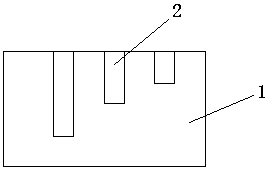

[0026] The oral cavity treatment of the present embodiment uses the MTA conveying board such as figure 1 with figure 2 As shown, the top surface of the conveyor plate body 1 is rectangular, and the top surface of the conveyor plate body 1 is provided with three grooves 2. The three grooves 2 are arranged side by side and one end is connected to the edge of the conveyor plate body. In this embodiment, the three grooves One end of 2 is connected with the same side edge of conveying plate body 1, and different grooves can also be set to communicate with different side edges of conveying plate body 1; the cross section of groove 2 is also rectangular, and the longitudinal section of groove 2 It is bow-shaped, and the direction of the side of the edge of the conveyor plate body 1 communicating with the groove is perpendicular to the setting direction of the groove 2 .

[0027] In this embodiment, the depths of the three grooves 2 are the same, the widths of the top surfaces are a...

Embodiment 2

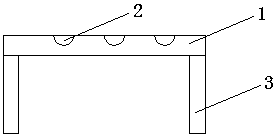

[0030] The oral cavity treatment of the present embodiment uses the MTA conveying board such as image 3 with Figure 4 As shown, the top surface of the conveyor plate body 1 is circular, and the top surface of the conveyor plate body 1 is provided with two grooves 2. The two grooves 2 are located on the same diameter and are oppositely arranged. The edge of the conveyor plate body 1 is connected; the cross section of the groove 2 is also rectangular, and the longitudinal section of the groove 2 is rectangular.

[0031] In this embodiment, the depths of the two grooves 2 are the same, the widths of the top surfaces are both 1.5 mm, and the lengths of the top surfaces are 3 mm and 5 mm respectively.

[0032] In this embodiment, a support foot 3 is provided in the middle of the bottom surface of the conveying plate body 1, and a boss is provided at the bottom of the support foot 3, which is convenient for the conveying plate to stand on a desktop or other places.

Embodiment 3

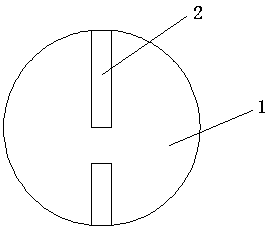

[0034] The oral cavity treatment of the present embodiment uses the MTA conveying board such as Figure 5 with Image 6 As shown, the top surface of the conveyor plate body 1 is trapezoidal, and the top surface of the conveyor plate body 1 is provided with a groove 2, and one end of the groove 2 communicates with the short edge of the top surface of the conveyor plate body; the cross section of the groove 2 is also in the shape of Rectangular, the longitudinal section of the groove 2 is arcuate, and the side direction of the edge of the conveying plate body 1 at the point where it communicates with the groove is perpendicular to the installation direction of the groove 2 .

[0035] In this embodiment, the width of the top surface of the groove 2 is 1 mm, and the length of the top surface is 4 mm. In this embodiment, two legs 3 are provided on the bottom surface of the conveyor plate body 1, and the two legs 3 are located at both ends of the bottom surface of the conveyor plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com